Light emitting device and method of manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[Embodiment 1]

This embodiment describes the structure of a light emitting of light emitting device according to the present invention. The description is given with reference to FIG. 6.

In FIG. 6, reference symbol 501 denotes a lower electrode, which is a film of a metal such as platinum (Pt), chromium (Cr), tungsten (W), or nickel (Ni). The lower electrode 501 corresponds to an anode. The role of the lower electrode 501 in this embodiment is to inject holes to an organic compound layer when a voltage is applied. Therefore, the material of the lower electrode 501 is required to be higher in HOMO level than the organic compound that forms the orgasmic compound layer. In other words, the lower electrode is desirably formed from a material having a large work function.

Next, a hole generating layer 504 is formed by co-evaporation of an electron acceptor 502 and a low molecular weight material 503. In this embodiment, the material of the electron acceptor 502 can be the same material give...

embodiment 2

[Embodiment 2]

This embodiment describes a case of forming a mixture layer in the light emitting element of Embodiment 1. The description will be given with reference to FIG. 7.

In FIG. 7, reference symbol 601 denotes a lower electrode and 602 denotes a hole generating layer that is formed by co-evaporation of an electron acceptor and a low molecular weight material.

A hole injection layer 603, a hole transporting layer 604, a light emitting layer 605, and an electron transporting layer 606 are laminated on the hole generating layer 602 to form an organic compound layer 607. Details about the methods of forming these layers may refer to Embodiment 1.

In this embodiment, the interface between the hole transporting layer 604 and the light emitting layer 605 and the interface between the electron transporting layer 606 and the light emitting layer 605 each have a mixture layer.

In this embodiment, the mixture layer formed at the interface between the light emitting layer 605 and the hole tr...

embodiment 3

[Embodiment 3]

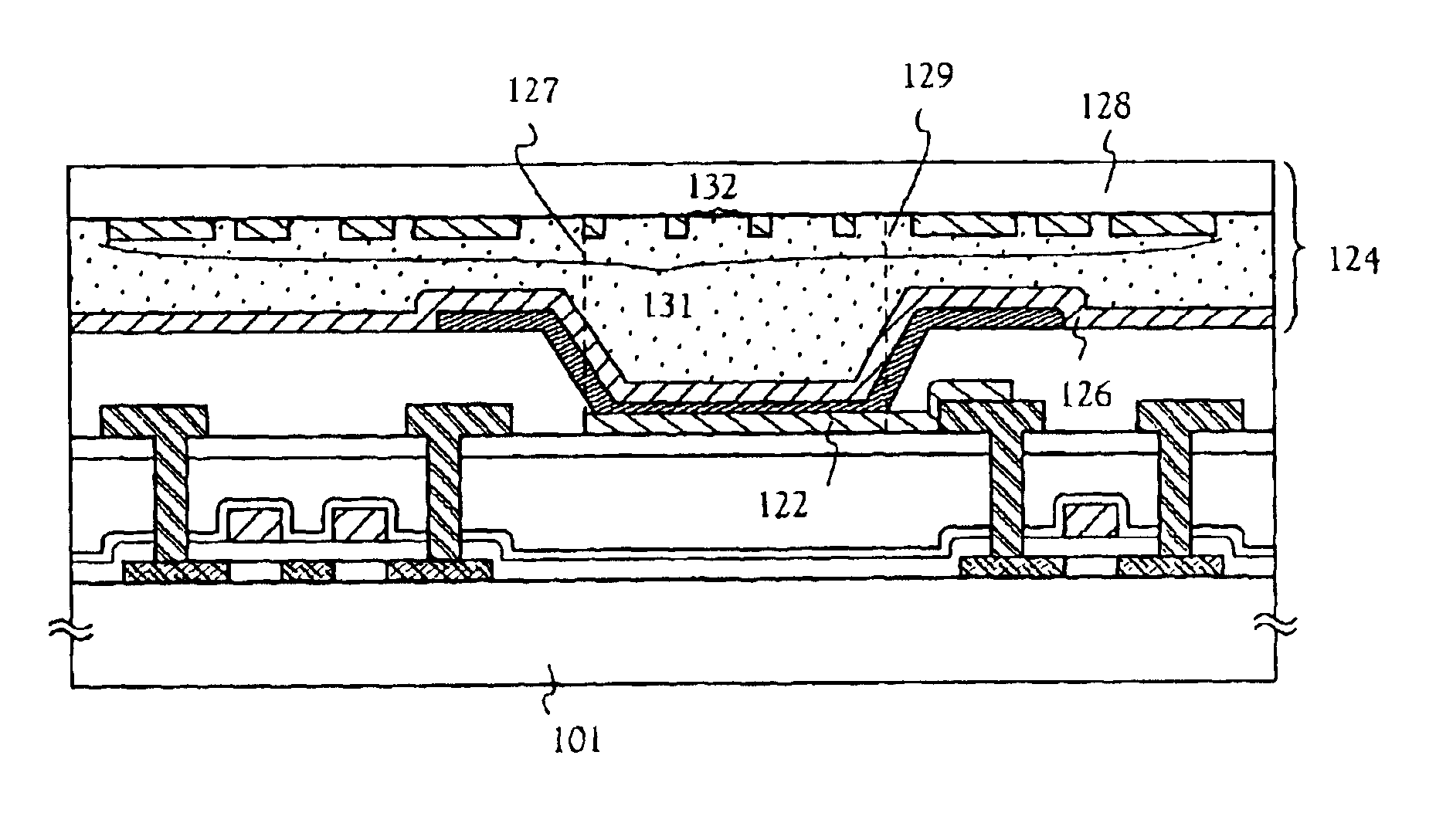

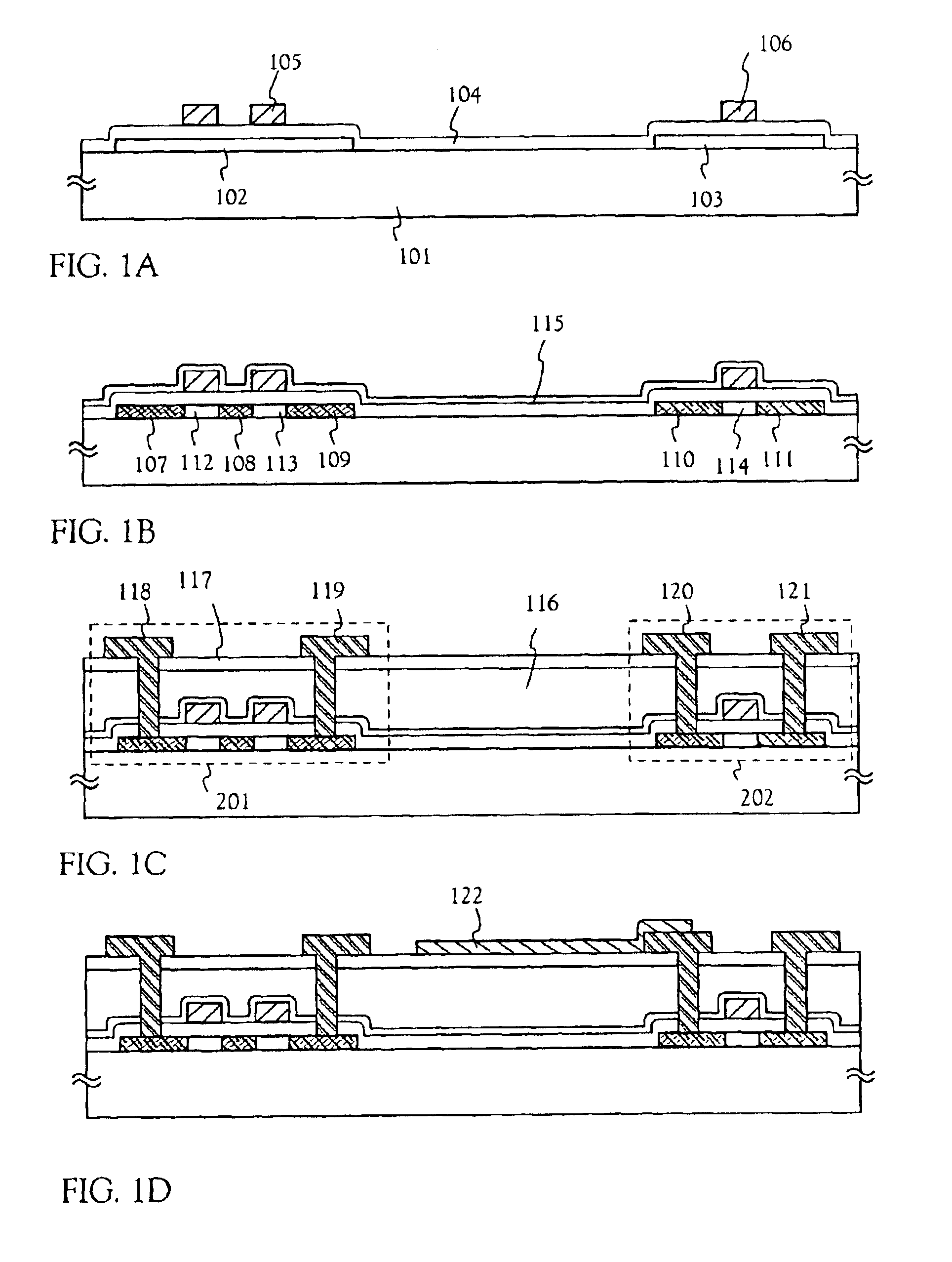

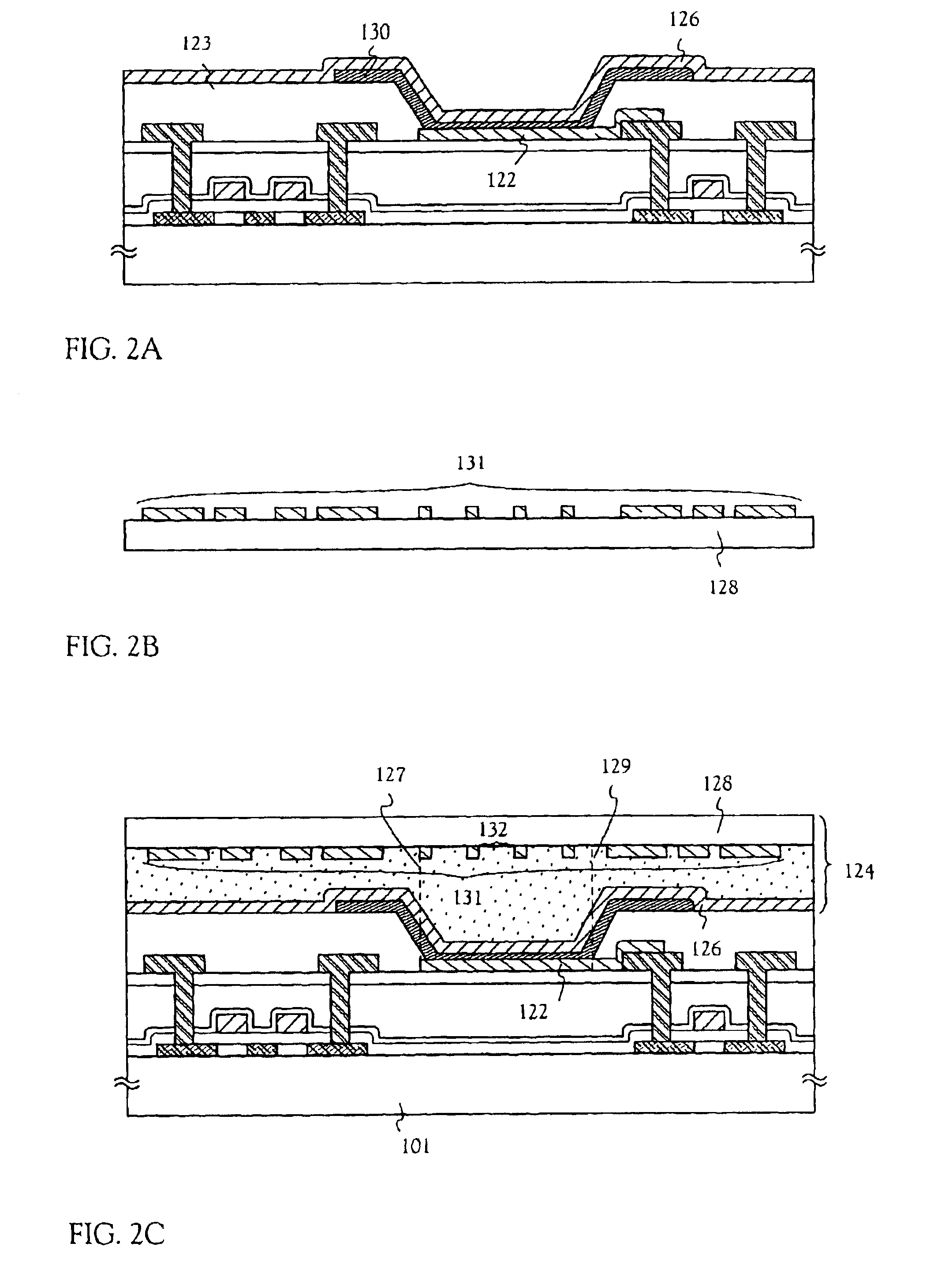

This embodiment gives a description on a light emitting device having light emitting elements that respectively emit red light, green light, and blue light. In this embodiment, a lower electrode 122 is formed as shown in FIG. 2A and then organic compound layers that emit light in different colors are formed by using different materials for their light emitting layers. All of the light emitting layers are formed by evaporation, which allows the use of metal mask in forming light emitting layers of pixels of different colors from different materials.

In this embodiment, a light emitting layer that emits light in red color (hereinafter referred to as red light emitting layer) is formed first using a metal mask. A known material can be used as the material of the red light emitting layer of this embodiment. All of the red light emitting layers to be formed in the light emitting device may be formed simultaneously. Alternatively, the red light emitting layers may be formed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com