Magnesium compound, solid catalyst component, catalyst for ethylene polymerization and method of producing ethylene polymer

a technology of ethylene polymerization and magnesium compound, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, chemical/physical process, etc., can solve the problems of letting the polymerization reactor be unstable, the flowability decreases, and the trouble of blocking the powder transport lin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

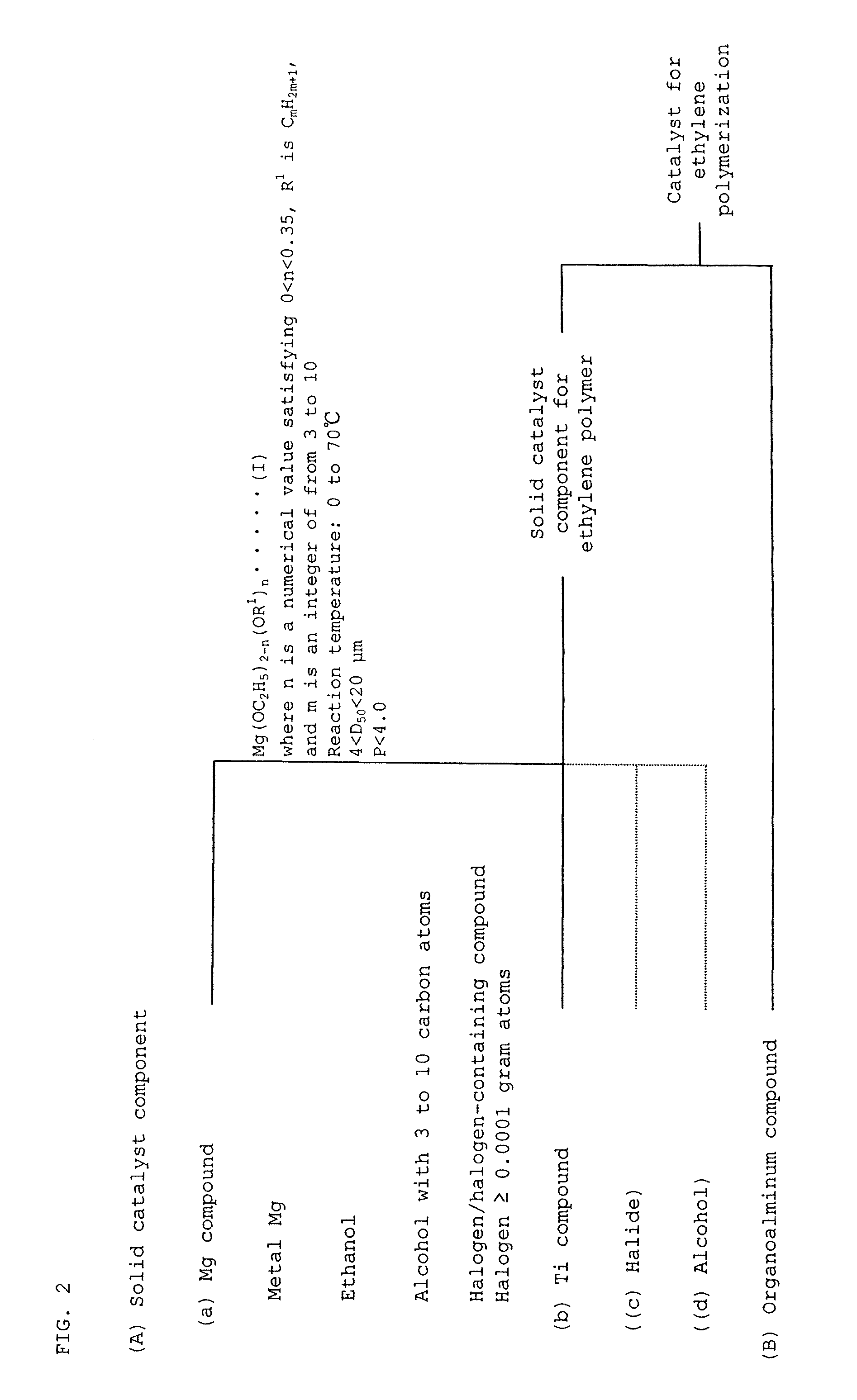

Method used

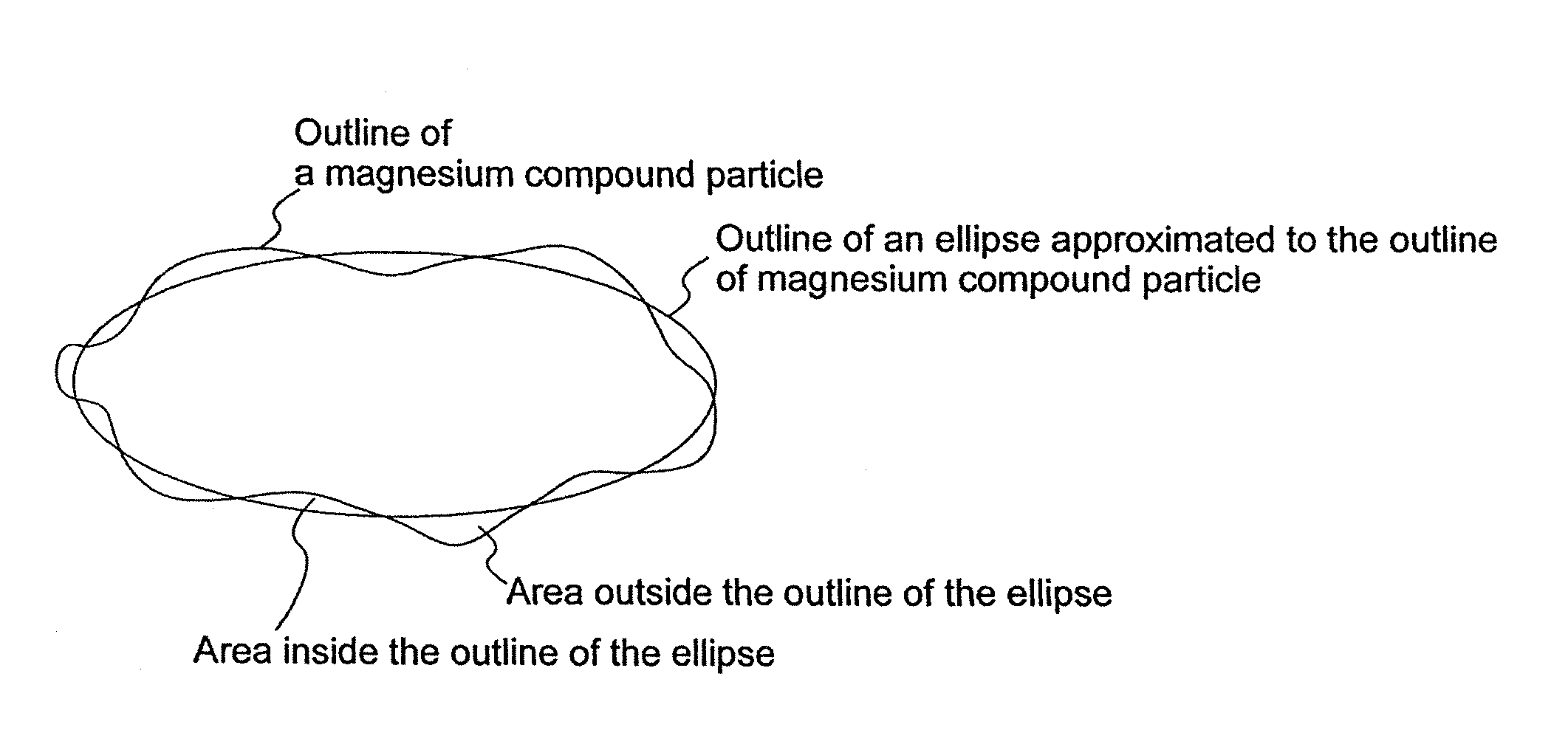

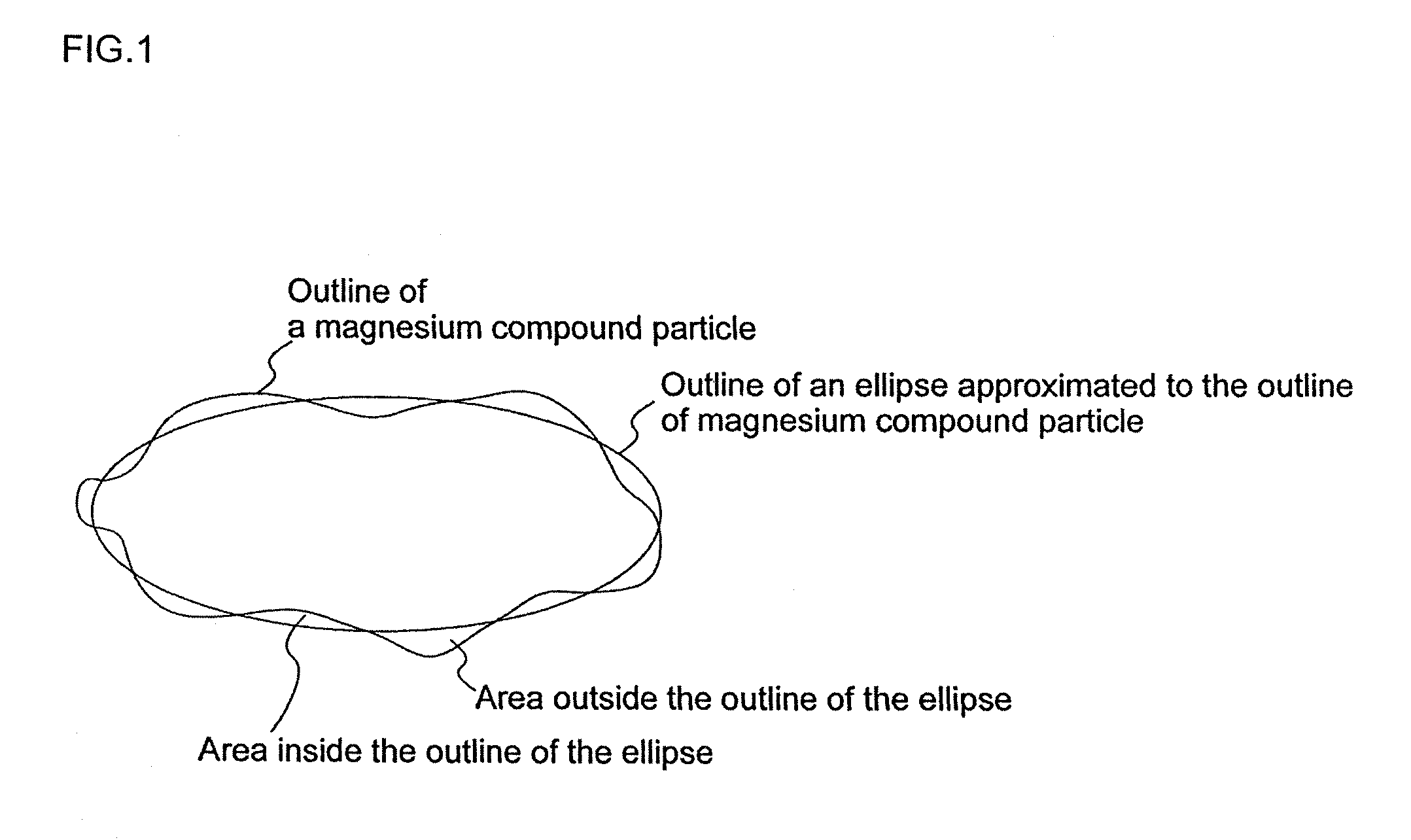

Image

Examples

example 1

(1) Preparation of Magnesium Compound

[0086]A reactor with max blend wing having an internal volume of 1 liter was flushed with nitrogen, and 608 ml (10.4 mole) of dehydrated ethanol, 67.7 ml (0.74 mole) of n-butanol, 0.18 g (1.4 milligram atom) of iodine and 36.0 g (1.48 milligram atom) of metal magnesium were poured into the reactor with “MAXBLEND®” blade wing and allowed to react at a reflux temperature (30° C.) with stirring (1,000 rpm) until no more hydrogen was generated from the system, to give a magnesium compound.

(2) Preparation of Solid Catalyst Component

[0087]A three-necked flask having an internal volume of 0.5 liter and equipped with a stirrer was flushed with nitrogen, and 15 g (131 mmole) of the magnesium compound obtained in the above (1) and 350 ml of hexane were placed in the three-necked flask. 4.9 mL (43 mmole) of silicon tetrachloride and 4.9 mL (64 mmole) of isopropanol were added to the mixture with stirring and reacted at 70° C. for 2 hours. Then 36 mL (0.33 m...

example 2

(1) Preparation of Magnesium Compound

[0091]Example 1 (1) was repeated except that 0.068 g (1.4 milligram atom) of anhydrous magnesium chloride was used instead of iodine.

(2) Preparation of Solid Catalyst Component

[0092]Example 1 (2) was repeated except that the magnesium compound prepared in the above (1) was used.

(3) Polymerization of Ethylene

[0093]Example 1 (3) was repeated except that the solid catalyst component prepared in the above (2) was used. Table 1 shows the results.

example 3

(1) Preparation of Magnesium Compound

[0094]Example 1 (1) was repeated except that the reaction temperature was set at 50° C.

(2) Preparation of Solid Catalyst Component

[0095]Example 1 (2) was repeated except that the magnesium compound prepared in the above (1) was used.

(3) Polymerization of Ethylene

[0096]Example 1 (3) was repeated except that the solid catalyst component prepared in the above (2) was used. Table 1 shows the results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter D50 | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| particle size distribution index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com