AlxInyGa1-x-yN mixture crystal substrate, method of growing same and method of producing same

a technology of mixture crystal substrate and alxinyga1, which is applied in the direction of crystal growth process, polycrystalline material growth, chemically reactive gas growth process, etc., can solve the problems of many defects in the aln film, and achieve the effect of absorbing material gasses higher and efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

Al0.8Ga0.2N Made on Sapphire Undersubstrate, Samples A, B, C and D; FIG. 11

[0243]FIG. 11 shows steps of making an Al0.8Ga0.2N substrate as Embodiment 1. A starting undersubstrate is a sapphire C-plane wafer 51. FIG. 11(1) denotes the sapphire undersubstrate 51. Sapphire has trigonal symmetry. Al0.8Ga0.2N has hexagonal symmetry. A “substrate” is different from an “undersubstrate”, here. Don't confuse a “substrate” with an “undersubstrate”. The undersubstrate is a starting plate. The substrate is a final product.

[0244]A 2 μm thick Al0.8Ga0.2N epi-layer 52 is preliminarily made on the sapphire undersubstrate 51 by an MOCVD method. Samples have an Al0.8Ga0.2N C-plane surface.

[0245]A 100 nm thick SiO2 film is formed upon the Al0.8Ga0.2N epi-layer 52 for distributing many seeds regularly and making a seed pattern on the epi-layer 52. The seed pattern 53 is a hexagonal pattern having many round dots 53 placed at corner points of equivalent equilateral triangles having a side aligning in t...

embodiment 2

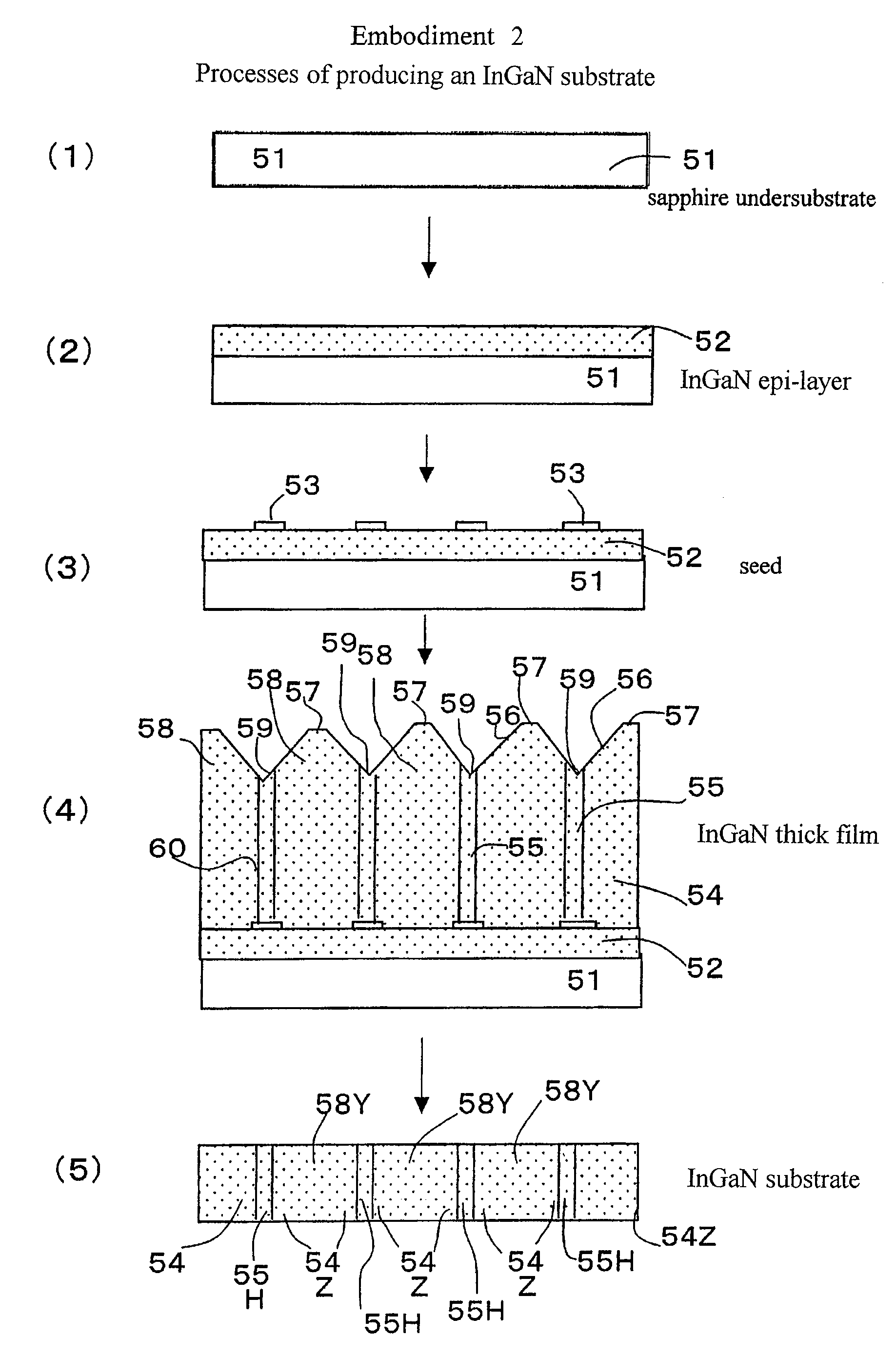

In0.9Ga0.1N on Sapphire Undersubstrate, FIG. 12

[0309]FIG. 12 shows steps of making an In0.8Ga0.1N substrate as Embodiment 2. A starting undersubstrate is a sapphire C-plane wafer 51. FIG. 12(1) denotes the sapphire undersubstrate 51. Sapphire has trigonal symmetry. In0.9Ga0.1N has hexagonal symmetry.

[0310]A 2 μm thick In0.9Ga0.1N epi-layer 52 is preliminarily made on the sapphire undersubstrate 51 by an MOCVD method. Samples have an In0.9Ga0.1N C-plane surface.

[0311]A 100 nm thick SiO2 film is formed upon the In0.9Ga0.1N epi-layer 52 for distributing many seeds regularly and making a seed pattern on the epi-layer 52. The seed pattern 53 is a hexagonal pattern having many round dots 53 placed at corner points of equivalent equilateral triangles having a side aligning in two dimensional directions without extra margin on the epi-layer. Seeds of SiO2 in the predetermined pattern are formed by etching other parts of round dots allotted on the corner points of the basic triangles by pho...

embodiment 3

Al0.3Ga0.3In0.4N: on GaAs, Si, Sapphire Substrate; Pattern A, H(=A+ELO); Samples J, K, L, M; FIG. 13

[0375]Embodiment 3 prepared three kinds of foreign material undersubstrates for making Al0.3Ga0.3In0.4N substrate crystals.

[0376]α. (111) GaAs undersubstrate

[0377]β. C-plane (0001) sapphire undersubstrate

[0378]γ. (111) Si undersubstrate

[0379]Silicon (Si) has the diamond structure of cubic symmetry group. Gallium arsenide (GaAs) has the zinc blende structure of cubic symmetry group. Al0.3Ga0.3In0.4N has hexagonal symmetry. In cubic symmetry crystals, only a (111) plane has three-fold rotation symmetry. Thus, a (111) plane is employed for Si and GaAs. Sapphire has trigonal symmetry which lacks three-fold rotation symmetry. Thought the c-axis does not have three-fold rotation symmetry, a (0001)C-plane sapphire can be utilized as an undersubstrate of Al0.3Ga0.3In0.4N growth.

[0380]FIG. 12(1), (2) and (3) show steps of the Al0.3Ga0.3In0.4N growth. Unlike Embodiments 1 and 2 Samples A to D, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| absorption light wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com