Atmospheric pressure plasma, generating method, plasma processing method and component mounting method using same, and device using these methods

a technology of atmospheric pressure and plasma, which is applied in the field of atmospheric pressure plasma, generating method, plasma processing method and component mounting method using same, and device using these methods. it can solve the problem that the method and device need only small electric power, and achieve the effect of high versatility and high productivity of the flat panel display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

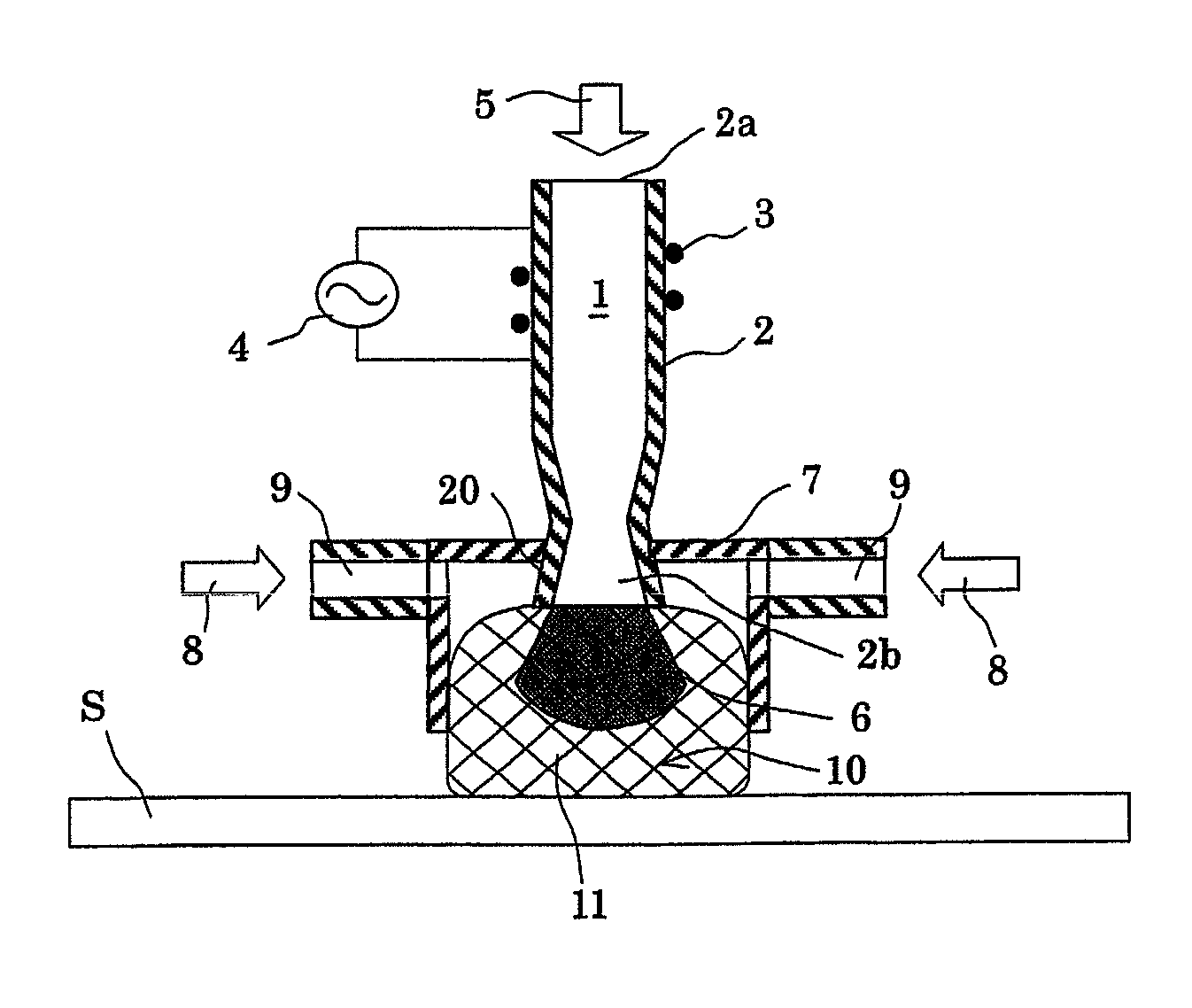

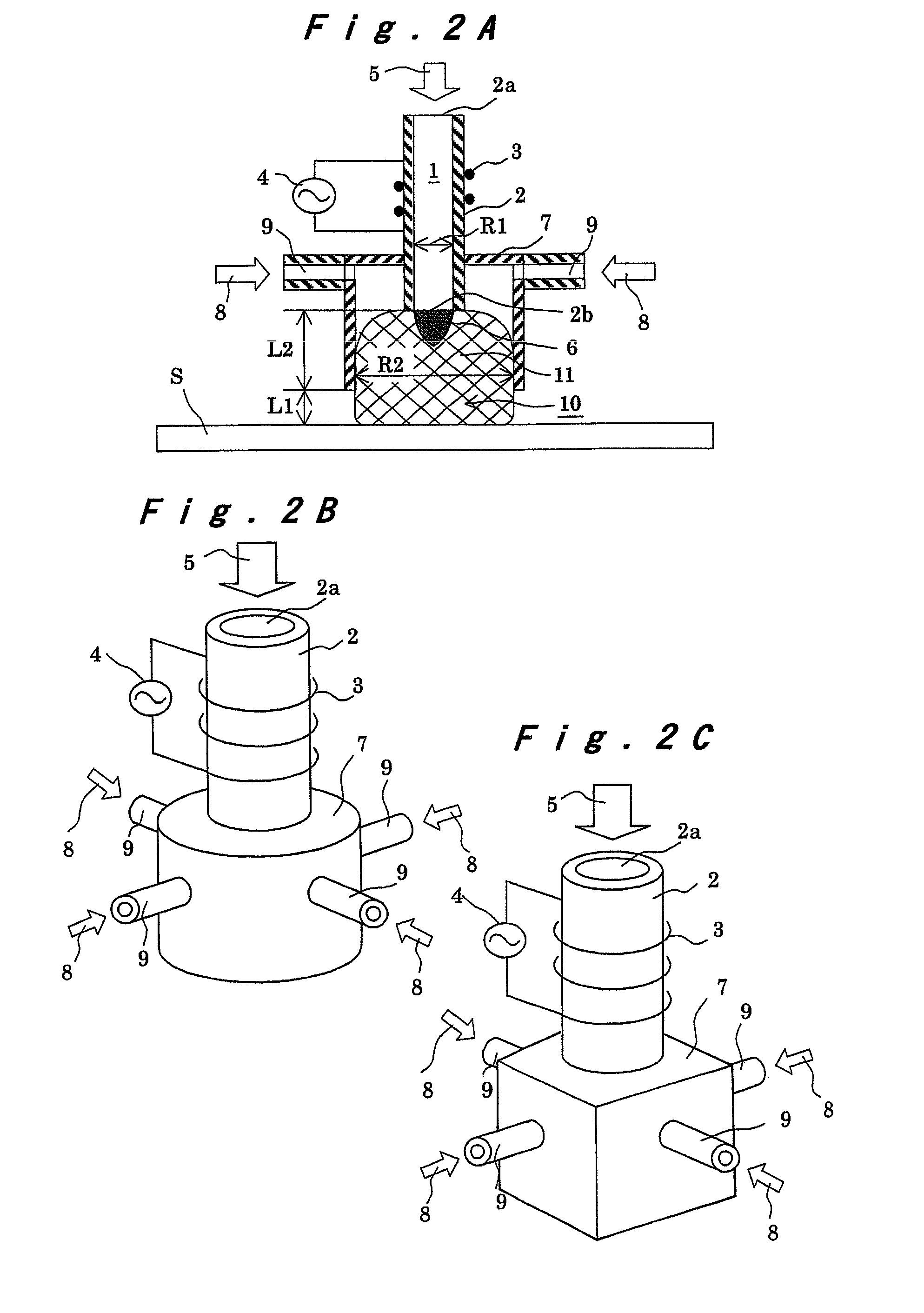

[0070]A first embodiment of an atmospheric pressure plasma generating device according to the present invention will now be described with reference to FIGS. 1 to 4B.

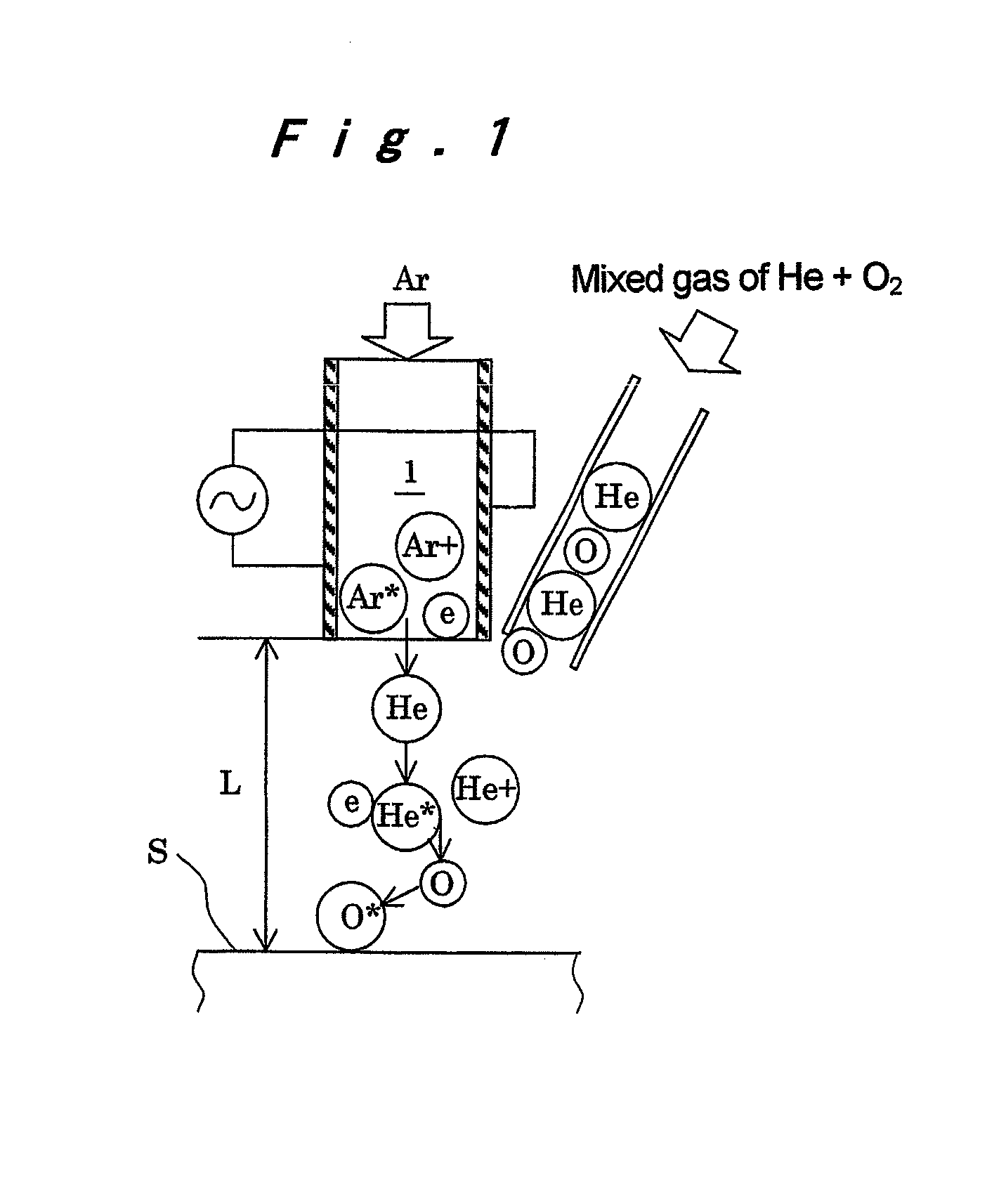

[0071]First, the principle of a method for generating an atmospheric pressure plasma according to the present invention will be described with reference to FIG. 1. FIG. 1 shows an example in which argon is used as a first inert gas, helium is used as a second inert gas, oxygen is used as a reactive gas, and a mixed gas of the second inert gas and the oxygen is supplied. Since argon is supplied and a high-frequency electric field is applied to a reaction space 1, argon atoms (Ar) in the reaction space 1 are excited or ionized by electrons (e) in a discharge plasma and become argon radicals (Ar*), argon ions (Ar+), and electrons (e). The argon radicals (Ar*) in a metastable state with high energy react with the same or different kinds of atoms in the vicinity thereof for the purpose of returning to a stable state by makin...

second embodiment

[0086]A second embodiment of the atmospheric pressure plasma generating device according to the present invention will now be described with reference to FIGS. 5A to 6B. In the description described below, the same reference numbers will refer to the same components as the foregoing embodiment and the description thereof will be omitted. Only differences will be mainly described.

[0087]The foregoing first embodiment disclosed an example in which the cylindrical reaction vessel 2 was used, the antenna 3 disposed on the periphery thereof applied the high-frequency electric field to the reaction vessel 1, and the mixed gas vessel 7 was disposed on the periphery of the lower end 2b of the reaction vessel 2. The second embodiment, as shown in FIGS. 5A and 5B, has a rectangular tube-shaped reaction vessel 14 with a slender rectangle in cross section serving as an plasma generating section, and a pair of electrodes 15a and 15b is disposed in its long walls opposite to each other. The whole ...

third embodiment

[0090]A third embodiment of the atmospheric pressure plasma generating device according to the present invention will now be described with reference to FIG. 7.

[0091]In the foregoing first and second embodiments, the mixed gas vessel 7 and 16 for supplying the mixed gas 8 was disposed on the periphery of the lower end of the reaction vessel 2 and 14. In this embodiment, as shown in FIG. 7, an inert gas vessel 18 for supplying a second inert gas 12 is disposed on the periphery or on both sides of the reaction vessel 2 and 14. A reactive gas vessel 19 for supplying a reactive gas 13 is disposed on the periphery or on both sides of the inert gas vessel 18, and a mixed gas area 10 is formed in the inside thereof by downwardly extending outside walls of the reactive gas vessel 19.

[0092]According to this structure, since a primary plasma 6 ejected from the reaction vessel 2 and 14 first collides with an atmosphere of only the second inert gas 12 supplied from the inert gas vessel 18, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com