High performance, thin metal lined, composite overwrapped pressure vessel

a composite overwrapped and pressure vessel technology, applied in the field of composite overwrapped pressure vessels, can solve the problems of not being able to fabricate a liner with the proper characteristics, not being able to withstand the weight of non-composite overwrapped metal tanks, and several failures, and achieve high ductility and high f.sup.ty/e

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

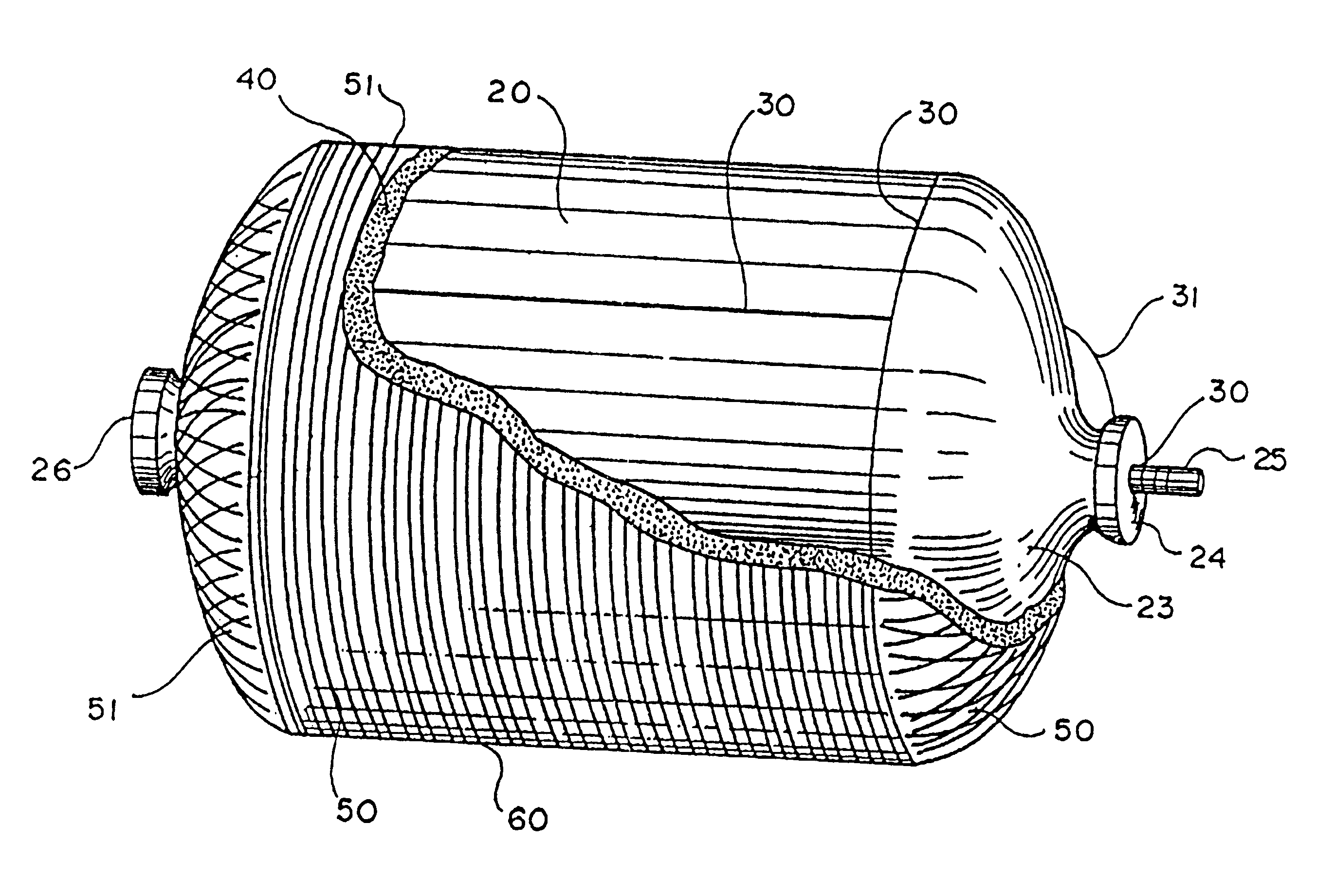

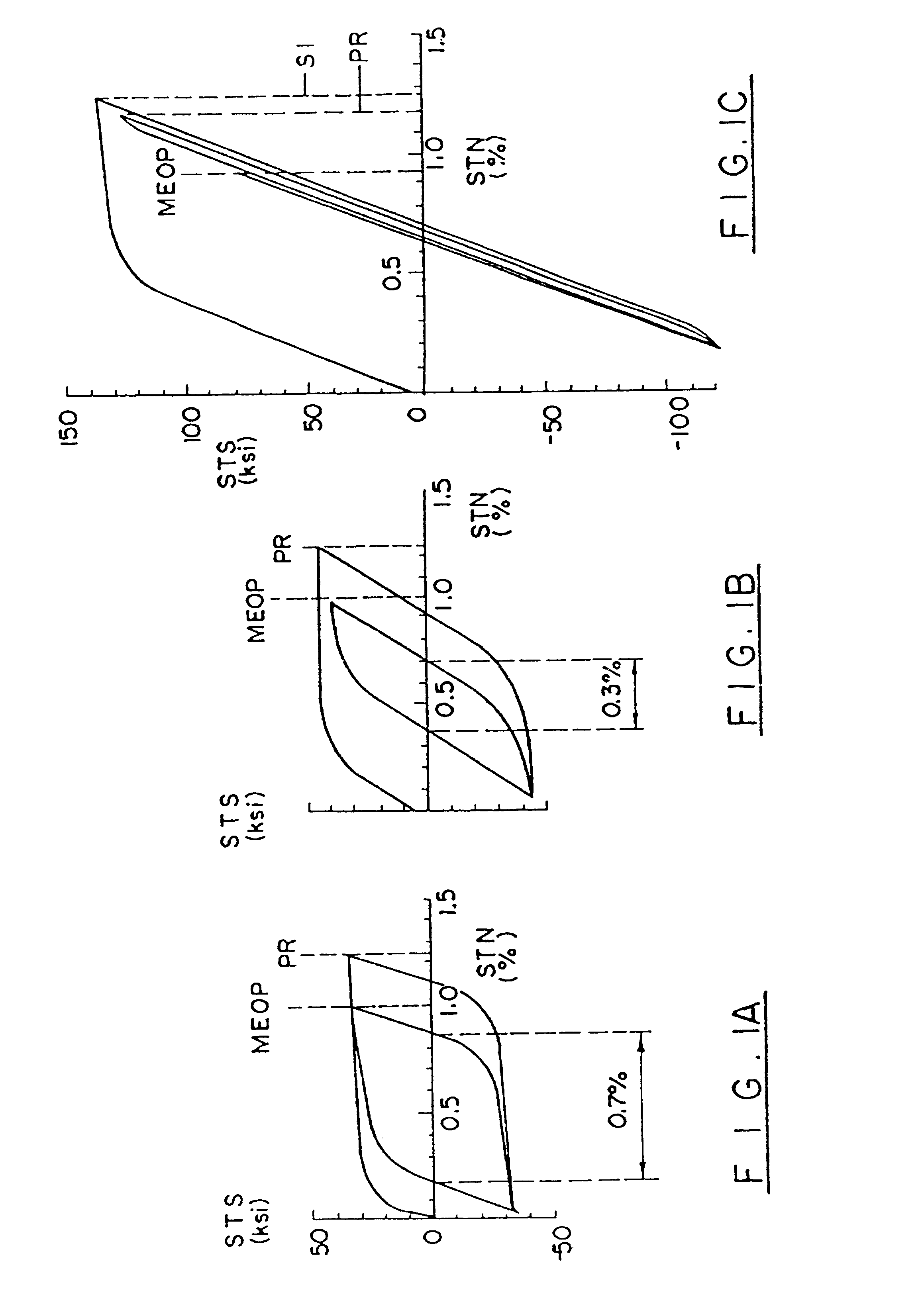

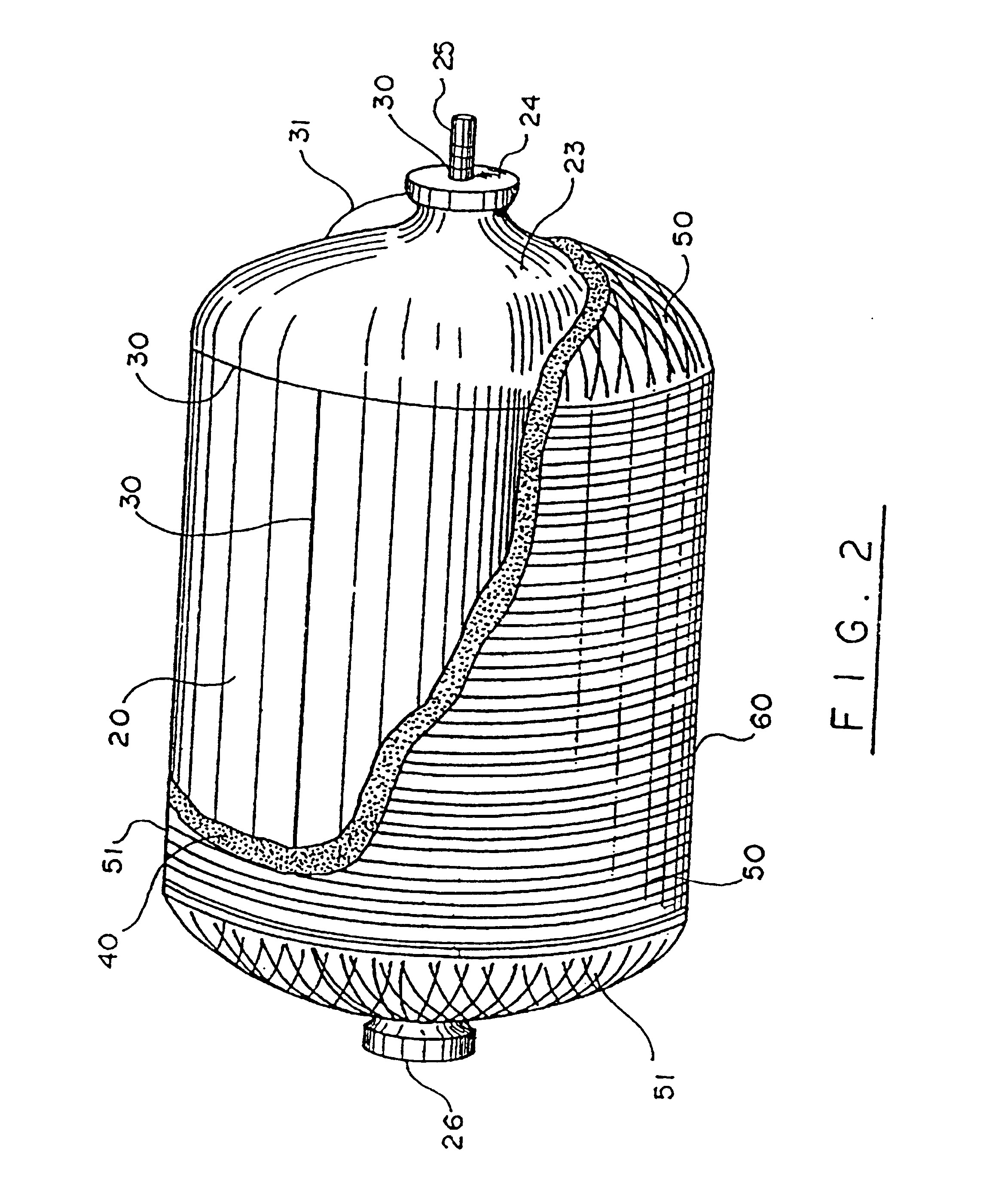

The following table lists the part numbers and part descriptions as used herein and drawings attached hereto. The preferred materials, if any, follow in parentheses.

PARTS LIST Part Number Description 10 COPV of the first embodiment of the present invention 20 liner (titanium-alloy) 20M maximum thickness of domes 21, 23 21 spun-formed dome (Ti-6Al-4V) 22 liner cylinder (Ti-6Al-4V) 23 spun-formed dome (Ti-6Al-4V) 24 machined boss (Ti-6Al-4V) 25 machined tube (Ti-6Al-4V) 26 machined boss (Ti-6Al-4V) 27 fitting used to test tank 28 holes in boss 24 29 holes in boss 26 30 EB welds 31 preferred region for boss / dome weld 40 adhesive (AF-191) 50 filament-wound graphite-epoxy overwrap (T-1000 / EPON 862- Curing Agent W) 51 graphite windings of filament-wound graphite-epoxy overwrap 50 60 epoxy coating (EPON 862-Curing Agent W) 120 liner (titanium-alloy) 120M maximum thickness of domes 121, 123 121 spun-formed dome (Ti-6Al-4V) 123 spun-formed dome (Ti-6Al-4V) 124 machined boss (Ti-6Al-4V) 126 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com