Anti-static resin composition containing fluorinated phosphonium sulfonates

a technology of phosphonium sulfonate and resin composition, which is applied in the field of anti-static resin composition, can solve the problems of affecting the appearance of smooth surfaces, affecting the transparency of articles, and accumulating static charges during processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

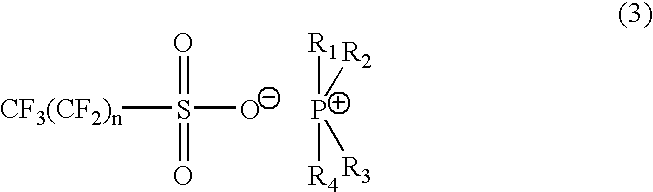

This Example describes the preparation of a fluorinated phosphonium sulfonate of this invention.

Potassium perfluorobutylsulfonate was used as the starting material. The potassium (K.sup.+ ion) was first exchanged for a H.sup.+ ion using an ion exchange column (Rohm & Haas, Amberjet 1200 H). A second step employed in this procedure was an acid-base reaction using a fluorocarbon tail sulfonic acid and tetra butyl phosphonium hydroxide resulting in a high yield and high purity fluorinated phosphonium sulfonate. The reaction is as follows: ##STR4##

tetrabutylphosphonium nonafluoro-1-butanesulfonate

example 2

This Example describes the preparation of a fluorinated phosphonium sulfonate of this invention.

Potassium nona-fluoro-ethoxyethyl sulfonate was used as the starting material. The potassium (K.sup.+ ion) was first exchanged for a H.sup.+ ion using an ion-exchange column (Rohm & Haas, Amberjet 1200 H). A second step employed in the procedure was an acid-base reaction using a fluorocarbon tail sulfonic acid and tetra butyl phosphonium hydroxide resulting in a high yield and high purity fluorinated phosphonium sulfonate.

The compound obtained had the following formula: ##STR5##

example 3

This example describes the preparation of a fluorinated phosphonium sulfonate of this invention.

Zonyl-TBS (DuPont), which is a mixture of different fluorocarbon containing sulfonic acids and fluorocarbon containing ammonium sulfonates was used as the starting material. The ammonium (NH.sup.+.sub.4 was first exchanged for an H.sup.+ - ion using an ion-exchange column (Rohm & Haas, Amberjet 1200 H). A second step employed in the procedure was an acid base reaction using the mixture of fluorocarbon tail containing sulfonic acids and tetra butyl phosphonium hydroxide. The compound mixture obtained consisted of the following components wherein y is an integer of 1-9. ##STR6##

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com