Ergosterol preparation method

A technology for ergosterol and ethanol, applied in the field of preparation of ergosterol, can solve the problems of low extraction rate of ergosterol, unstable saponification, long time, etc., and achieves high saponification efficiency, simplified refining and filtration process, and high recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

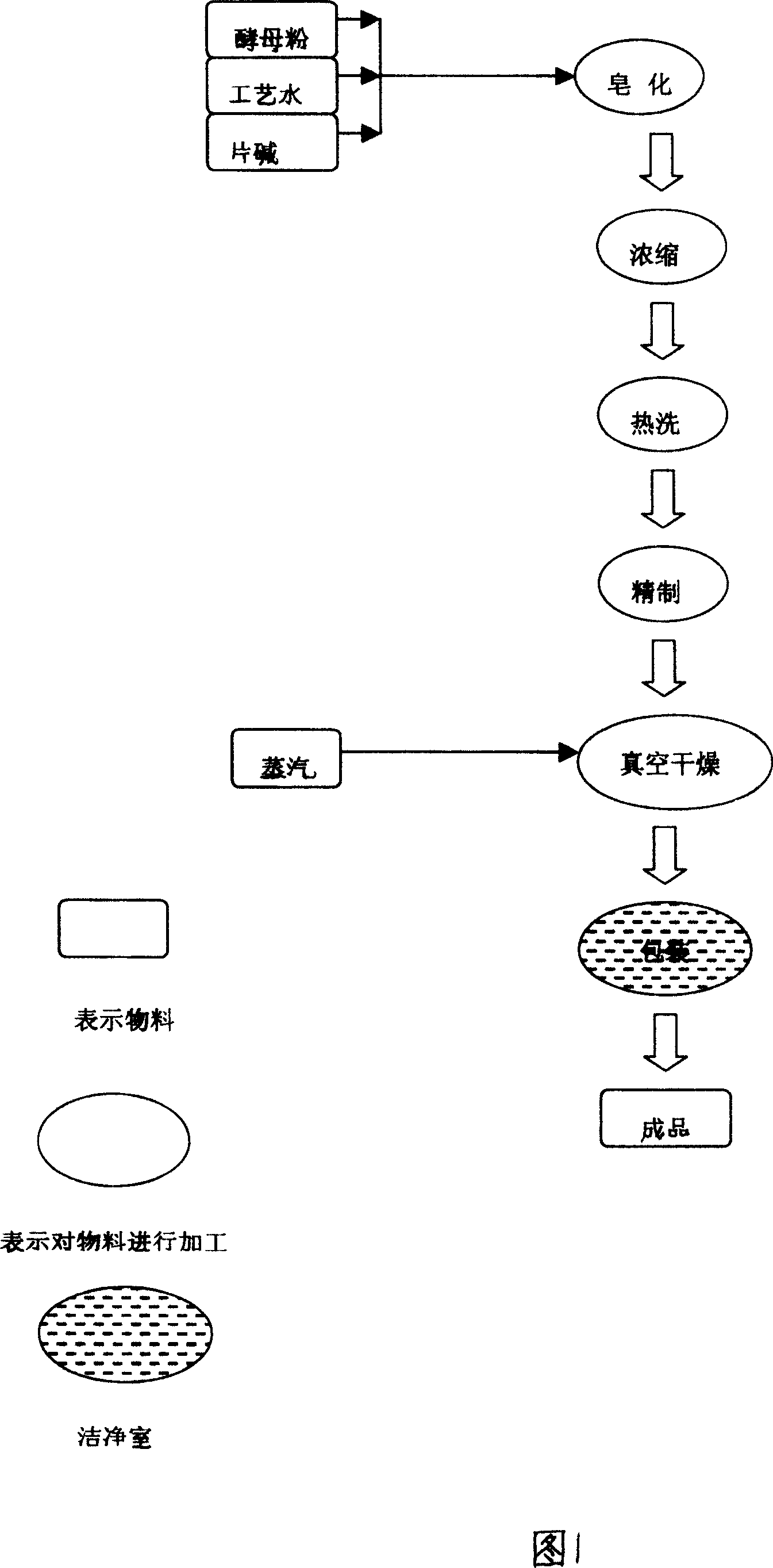

Image

Examples

Embodiment 1

[0023] raw material:

[0024] 1. Yeast powder is medicinal yeast with a total sterol content of more than 10‰.

[0025] 2. Ethanol is used for medicine and contains C 2 h 5 OH95% or more, aldehyde≤0.0030%.

[0026] 3. Toluene is industrially pure, colorless, transparent, volatile and flammable liquid, can be mixed with alcohol, aldehyde, chloroform, acetone, carbon disulfide and glacial acetic acid, etc., slightly soluble in water. The specific gravity is 0.866, the flash point is 6-10°C, the boiling point is 110.8°C, and the melting point is -9.5°C. Its steam can form an explosive mixture with air, and its explosion limit is 1.27-7% (volume);

[0027] 4. Sodium chloride NaCl;

[0028] 5. Sodium hydroxide NaOH;

[0029] 6. Activated carbon is 767 type, for injection;

[0030] Process steps:

[0031] 1) Saponification: use dry yeast powder, add sodium hydroxide according to the ratio of dry yeast powder: sodium hydroxide = 1: 0.5, add dry yeast powder: sodium chloride =...

Embodiment 2

[0040] Raw material is identical with embodiment 1.

[0041] Process steps:

[0042] 1) Saponification: use dry yeast powder, add sodium hydroxide according to the ratio of dry yeast powder: sodium hydroxide = 1: 0.7, and add in the ratio of dry yeast powder: sodium chloride = 1: 0.3 according to 500 kg per pot Sodium chloride, the saponification temperature is 118-120°C, and the saponification time is 4-6 hours;

[0043] 2) Add toluene for extraction: add 1500 liters of toluene into the saponification pot three times, 600 liters for the first time, 500 liters for the second time, 400 liters for the third time, the temperature is 60-80 °C, and the standing time is 1 hour / every time;

[0044] 3) Extraction of toluene ergosterol liquid: in the saponification pot, extract the clear layered toluene ergosterol liquid into the washing tank, wash with boiling water three times, the amount of boiling water each time is 200-300 liters, and then transfer to Concentrate in the concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific rotation | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com