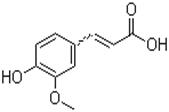

Method for separating and extracting natural ferulic acid from rice bran oil nigre containing oryzanol

A technology of rice bran oil and oryzanol, which is applied in the field of plant extraction and separation, can solve the problems of low efficiency of natural ferulic acid, environmental pollution and complicated processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for separating and extracting natural ferulic acid from rice bran oil soapstock containing oryzanol is:

[0048] (1) Saponification: Add 3 times the weight of sodium hydroxide according to the weight of rice bran oil saponin oryzanol, add water to make the concentration of lye 25%, calculate with the total volume of water added and the water in the raw material, and add a mass volume ratio of 1 % sodium metabisulfite, and ammonium sulfate with a mass volume ratio of 2% are stirred and dissolved; rice bran oil soapstock containing oryzanol content is put into a heating reaction kettle, and the temperature is adjusted to 95°C, while carbon dioxide is pressurized to maintain a pressure of 4kgf / m2, and high-speed stirring Lower saponification for 4 hours;

[0049] (2) Extraction: After saponification, recover carbon dioxide gas for the next cycle, add 3 times the volume of raw material purified water, stir and extract for 30 minutes, filter naturally with a 100-mes...

Embodiment 2

[0057] A method for separating and extracting natural ferulic acid from rice bran oil soapstock containing oryzanol is:

[0058] (1) Saponification: add 3 times the weight of sodium hydroxide according to the weight of rice bran oil saponin oryzanol, add water to make the concentration of lye 28%, and calculate based on the total volume of the added water and the water in the raw material, the added mass volume ratio is 2 % sodium pyrosulfite, and ammonium sulfate with a mass volume ratio of 2% are stirred and dissolved; rice bran oil soapstock containing oryzanol content is put into a heating reaction kettle, and the temperature is adjusted to 95-98°C, while carbon dioxide is pressurized to maintain a pressure of 3kgf / m2, Saponification under high-speed stirring for 3 hours;

[0059] (2) Extraction: After saponification, recover carbon dioxide gas for the next cycle, add 2 times the volume of raw material purified water, stir and extract for 30 minutes, filter naturally with ...

Embodiment 3

[0067] A method for separating and extracting natural ferulic acid from rice bran oil soapstock containing oryzanol is:

[0068] (1) Saponification: Add 4 times the weight of sodium hydroxide according to the weight of rice bran oil saponin oryzanol, add water to make the concentration of the lye 30%, calculate based on the total volume of the added water and the water in the raw material, and add a mass volume ratio of 2 % sodium metabisulfite, and ammonium sulfate with a mass volume ratio of 1% are stirred and dissolved; rice bran oil soapstock containing oryzanol content is put into a heating reaction kettle, and the temperature is adjusted to 95-100°C, while carbon dioxide is pressurized to maintain a pressure of 5kgf / m2, Saponification under high-speed stirring for 5 hours;

[0069] (2) Extraction: After saponification, recover carbon dioxide gas for the next cycle, add 4 times the volume of raw material purified water, stir and extract for 30 minutes, filter naturally wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com