Production method of lubricating grease

A production method and technology of lubricating grease, applied in the directions of lubricating composition, petroleum industry, etc., can solve the problem of not realizing large-scale, continuous production, etc., and achieve the effects of being conducive to civilized production, large operation flexibility, and delicate appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

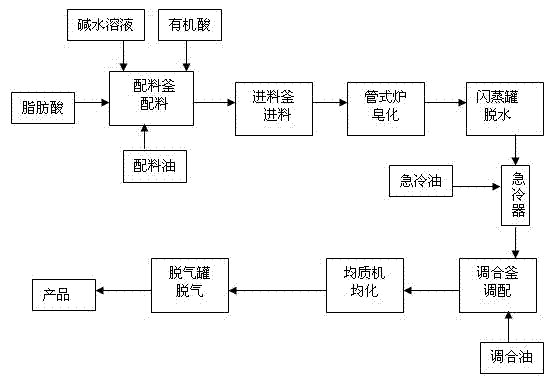

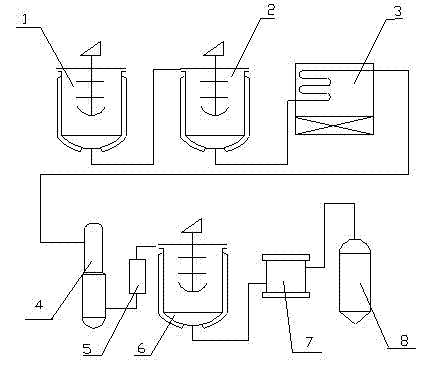

[0050] The production method of the lubricating grease that the present embodiment enumerates comprises the following processing steps:

[0051] (1) Ingredients:

[0052] Heat up about 2 / 3 base oil (2500kg of ingredient oil), 480kg of lauryl hydroxystearic acid, 120kg of azelaic acid, 32kg of boric acid and 136kg of lithium hydroxide monohydrate aqueous solution (the mass ratio of water to alkali is 2:1) to 60-85°C, stir in the batching tank for 20-30 minutes to mix evenly, after the material is transferred to the feeding tank (at the same time, the second tank material is prepared in the batching tank to ensure continuous feeding production), start the pump cycle, and the feeding The material in the feed kettle is pumped into the tube furnace.

[0053] (2), saponification reaction:

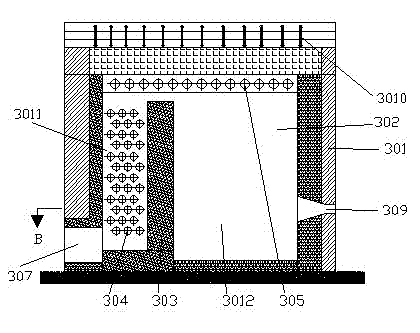

[0054] The mixed material is subjected to saponification reaction and high-temperature compounding and refining in a tube furnace (heat convection coil, heat radiation coil). The time is 8-10 ...

Embodiment 2

[0063] raw material: Dodecyl hydroxystearic acid 400 kg, adipic acid 76 kg, boric acid 20 kg, lithium hydroxide monohydrate 112 kg, about 2 / 3 of the base oil (2300 kg of ingredient oil) saponification, about 1 / 3 of the base oil (blend oil 1500 kg) adjustment The consistency of grease product; Technology is with embodiment 1, and additive is with embodiment 1.

[0064] The saponification rate of the lubricating grease in this embodiment is 99.6%, and the performance testing indexes are shown in Table 4.

Embodiment 3

[0066] raw material: Lauryl hydroxystearic acid 400 kg, sebacic acid 112 kg, boric acid 28 kg, lithium hydroxide monohydrate 116 kg, about 2 / 3 of base oil (2500 kg of ingredient oil) saponification, about 1 / 3 of base oil (blend oil 1500 kg) adjustment The consistency of grease product; Technology is with embodiment 1, and additive is with embodiment 1.

[0067] The saponification rate of the lubricating grease of this embodiment is 99.4%, and the performance testing indexes are shown in Table 4.

[0068]

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com