Rareearth magnet and making method therefor

A rare earth magnet and manufacturing method technology, applied in the direction of inductor/transformer/magnet manufacturing, magnetic materials, magnetic objects, etc., can solve the problems of insufficient improvement of magnet characteristics, changes in magnetic characteristics, low production efficiency, etc. The effect of improving magnetic properties and reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

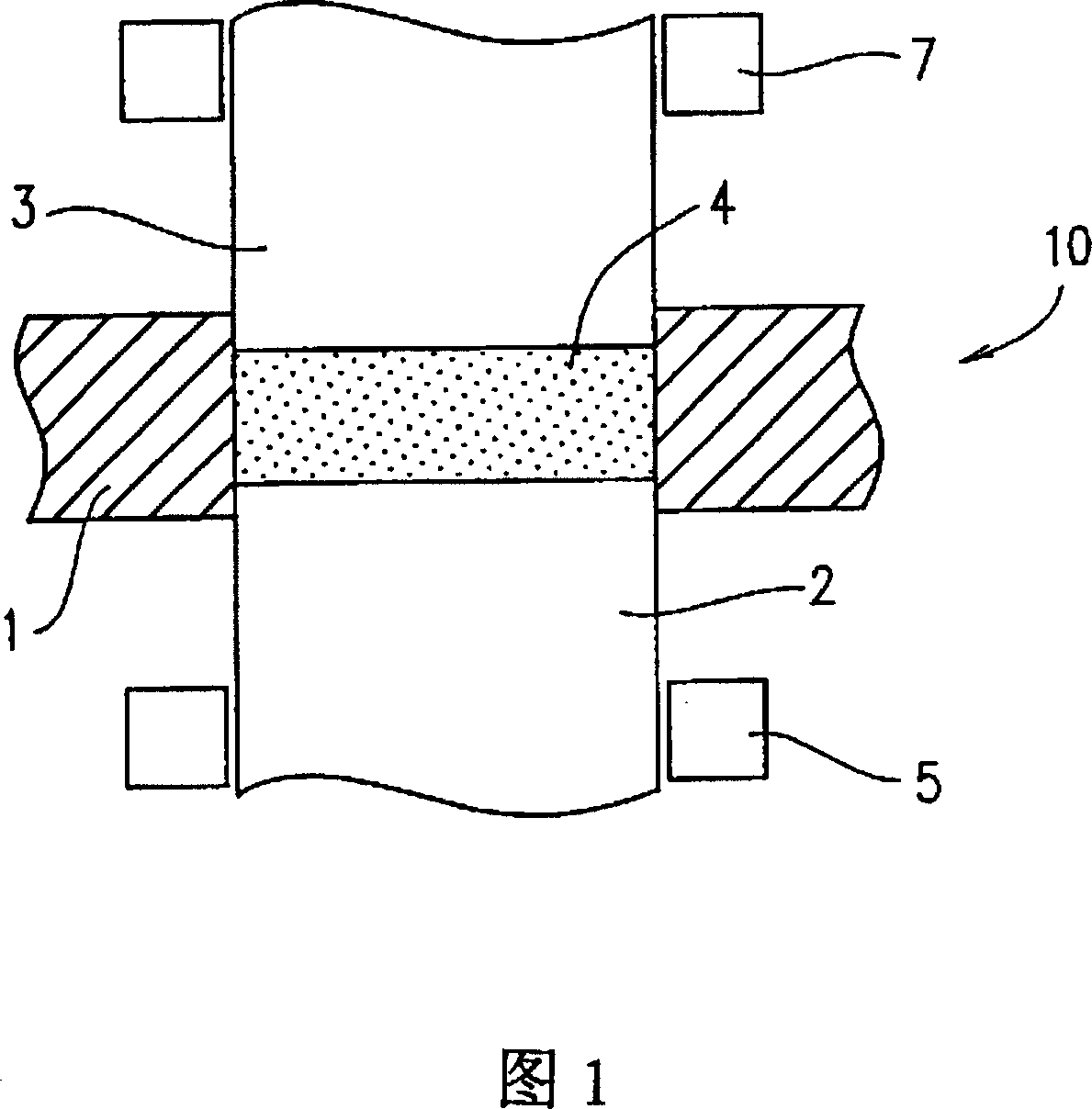

[0040] The R-Fe-B-based rare earth magnet in this embodiment has an average grain size of 3 μm to 9 μm, an oxygen concentration of 50 ppm to 4000 ppm by weight, and a nitrogen concentration of 150 ppm to 1500 ppm by weight. The "R-Fe-B-based rare earth magnet" here broadly includes a rare earth magnet in which a part of Fe is replaced by a metal such as Co and a part of B (boron) is replaced by C (carbon). The R-Fe-B series rare earth magnet has R-rich phase and B-rich phase (grain boundary phase) surrounded by R with a square crystal structure. 2 Fe 14 The organizational structure around the main phase composed of type B compounds. The structure of the R-Fe-B rare earth magnet is disclosed in US Patent No. 5,645,651.

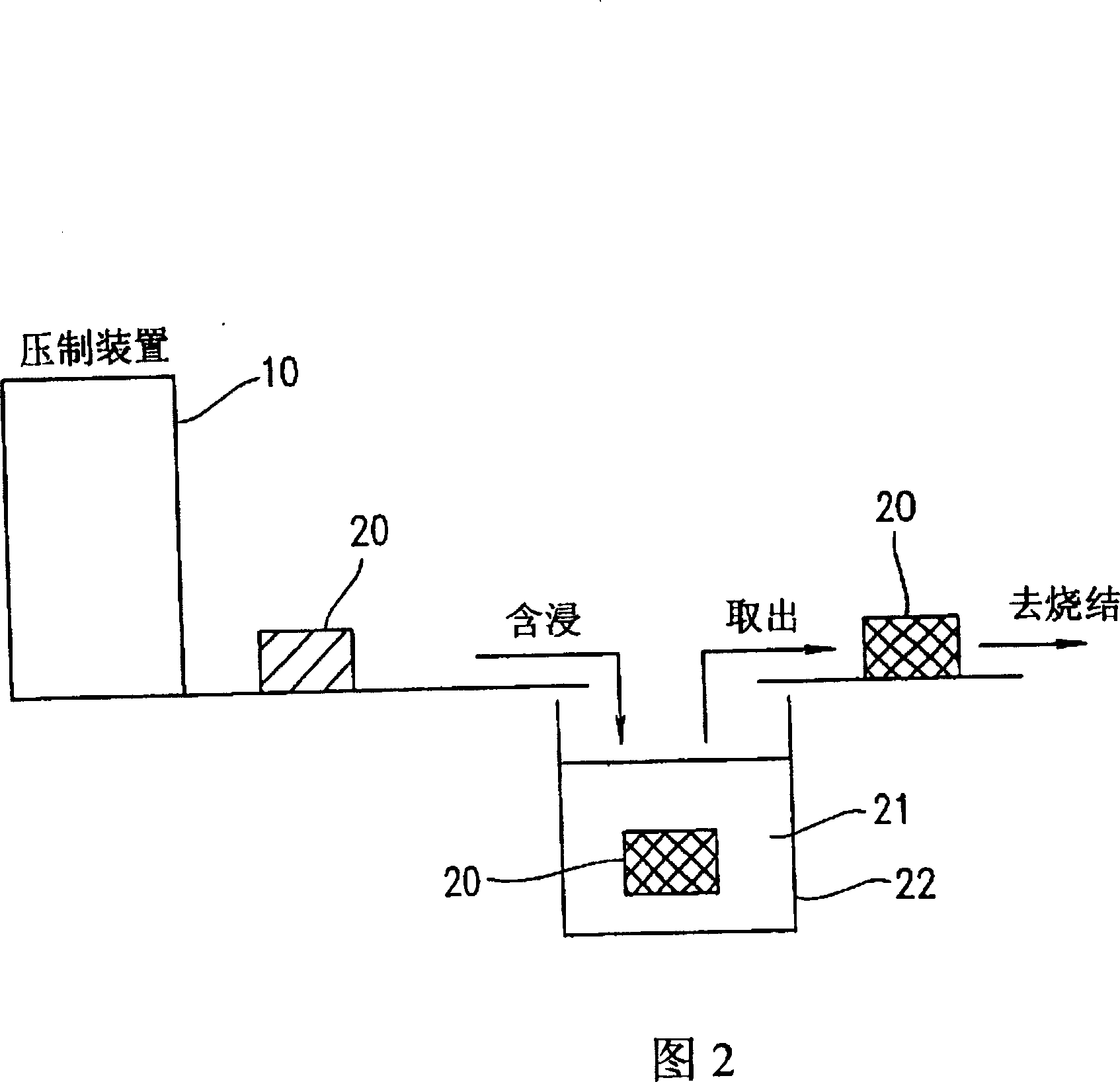

[0041] A preferred embodiment of the method for producing such a rare earth magnet will be described in detail below.

[0042] First, R- Melt of Fe-B alloy. A part of Fe may be substituted with one or both of Co and Ni, and a part of B may be substituted w...

Embodiment 1

[0063] First, an alloy molten liquid composed of Nd+Pr (30.0% by mass)-Dy (1.0% by mass)-B (1.0% by mass)-Fe (the rest) is produced in a high-frequency melting furnace, and a water-cooled roll-type strip is used The casting method cools the above-mentioned molten liquid to produce a thin plate-shaped cast piece (flaky alloy) with a thickness of about 0.5 mm. The oxygen concentration of this flaky alloy was 150 mass ppm.

[0064] Next, the flake-shaped alloy was charged into a hydrogen furnace, and after the furnace was evacuated, hydrogen gas was supplied to the furnace for 2 hours to carry out hydrogen embrittlement. The hydrogen partial pressure in the furnace was 200 kPa. After absorbing hydrogen, the flakes will naturally collapse, and after that, dehydrogenation treatment is carried out by vacuumizing while heating. Argon gas was then introduced into the furnace and cooled to room temperature. When the alloy temperature is cooled to 20°C, it is taken out from the hydro...

Embodiment approach 2

[0082] A second embodiment of the present invention will be described below.

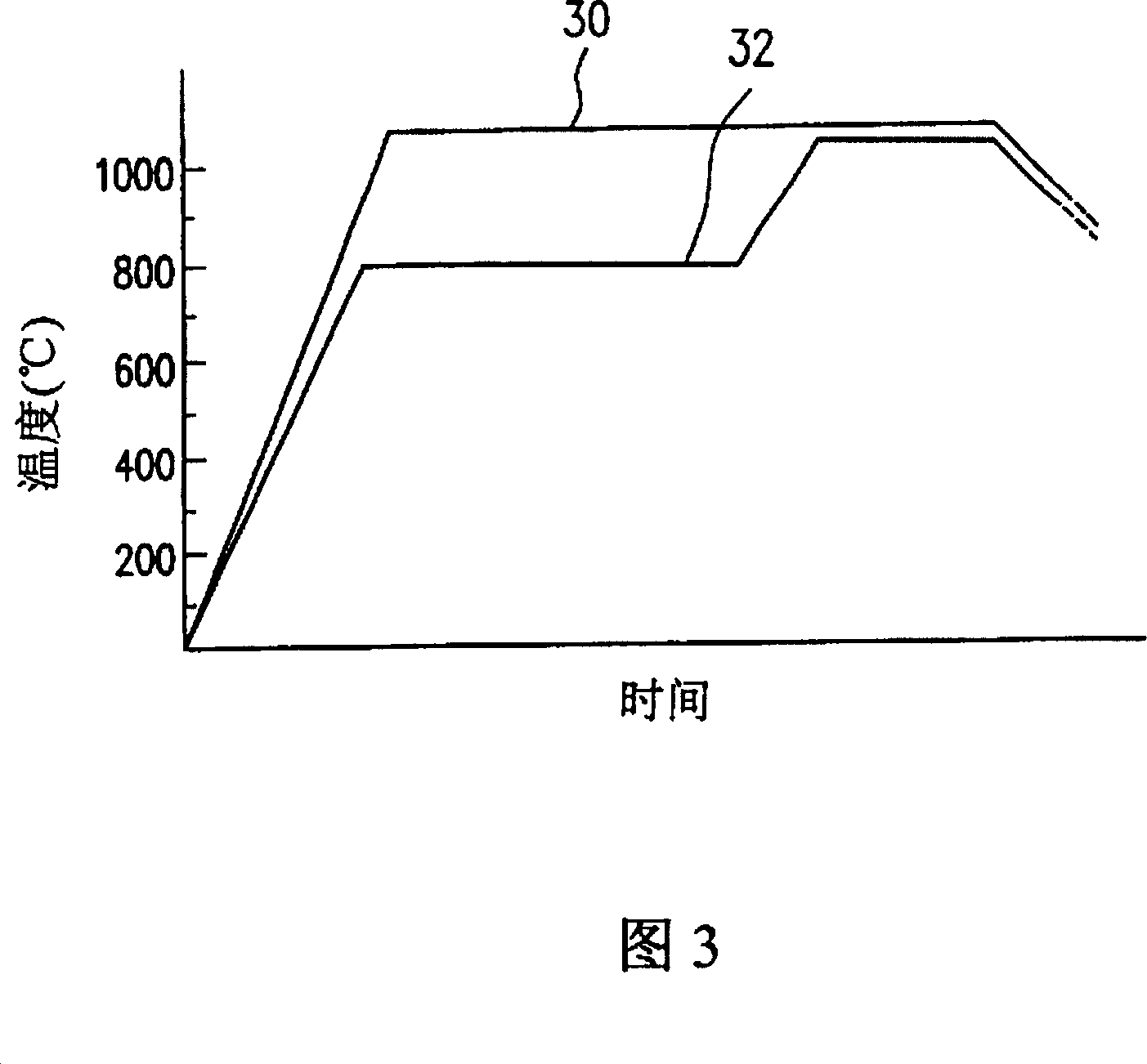

[0083] As in the above-mentioned embodiment, trying to suppress the oxygen content and obtain a high-performance R-Fe-B-based rare earth magnet, it is possible to increase the residual magnetic flux density B while maintaining a high coercive force. r . However, in the first embodiment described above, depending on the sintering conditions, the magnetic properties may be deteriorated (in particular, the coercive force may be lowered), and a sufficient sintered density may not be obtained. Such a problem remarkably exists when the amount of the rare earth element is small, for example, 32% by mass or less. In order to mass-produce the rare earth sintered magnet, the amount of the rare earth element in the magnet is preferably in the range of 29% by mass or more. And, considering the residual magnetic flux density B r and coercive force H cj , preferably in the range of 29.5 to 32% by mass. There...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com