Method for producing ethyl benzene through alkylation in gas phase

A gas-phase alkylation and alkylation technology, which is applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of uneven gas flow distribution of reactants and insufficient utilization of catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

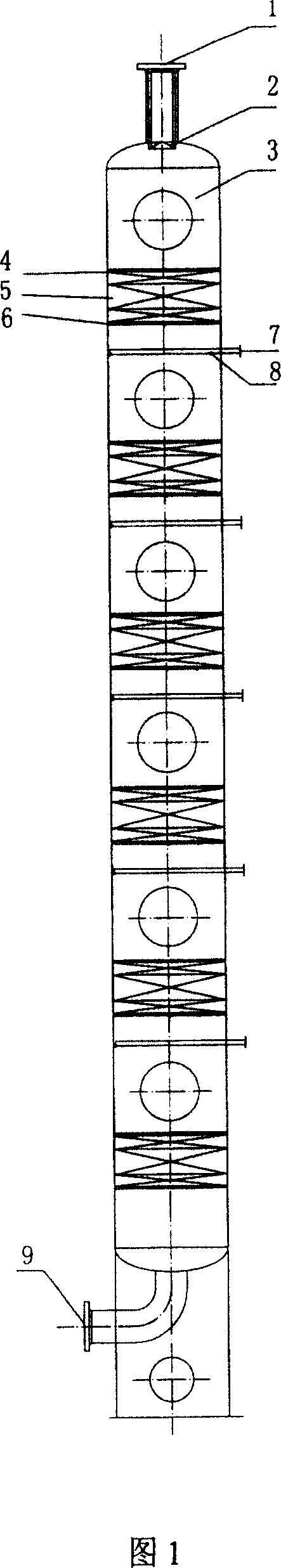

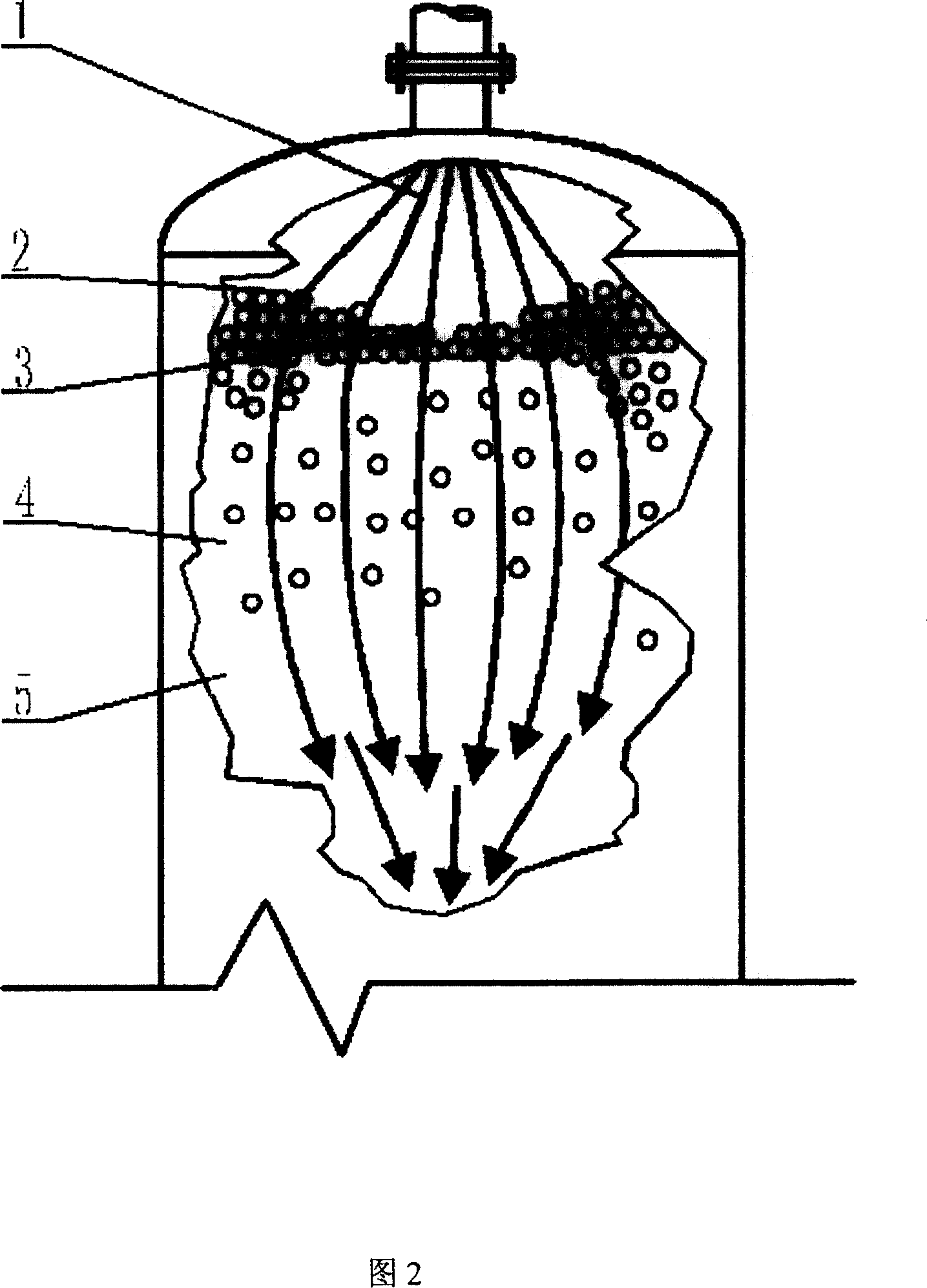

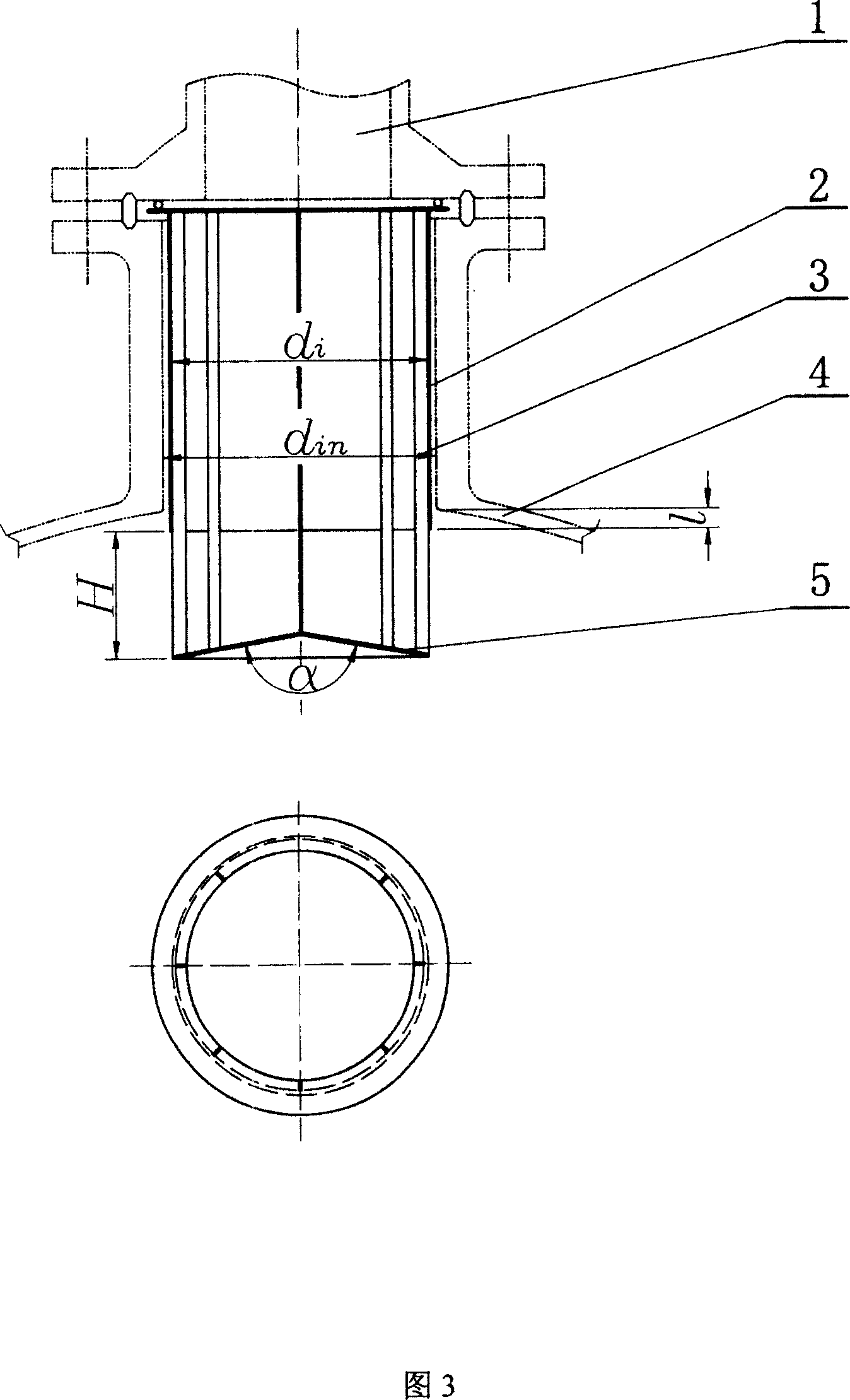

[0023] The 15,000 tons / year ethylbenzene unit in a factory adopts molecular sieve gas-phase alkylation process. The alkylation reactor is a 4-stage layered adiabatic fixed-bed reactor. The inner diameter of the reactor is φ600, and the inner diameter of the inlet pipe is d in =200 mm, adopt conical single-stage baffle type inlet gas pre-distributor as shown in Figure 3, its cylinder inner diameter d i =170 mm, cone angle α=150°, ring gap height H=50 mm. The height of the homogenization space inside the reactor is 1150 mm, and the catalyst bed heights from top to bottom are 310, 345, 380, 430, 480, and 890 mm, and the upper and lower ceramic ball layers are made of inert alumina ceramic balls. The thickness is 180mm. There are 3 inter-stage calandria gas distributors, the diameter of the main pipe is φ50, 6 branch pipes, the diameter is φ20, and the number of openings is 32. The opening diameters of the 3 calandria gas distributors are 4, 4.5, 5 mm, the angle between the hole...

Embodiment 2

[0027] The 30,000 tons / year ethylbenzene unit of a factory adopts molecular sieve gas-phase alkylation process. The alkylation reactor is a 6-stage layered adiabatic fixed-bed reactor with an inner diameter of φ700 and an inner diameter of the inlet pipe d in =250 mm, adopt conical single-stage baffle type inlet gas pre-distributor as shown in Figure 3, its cylinder inner diameter d i =200 mm, cone angle α=120°, ring gap height H=50 mm. The height of the homogenization space inside the reactor is 1650 mm, and the height of the catalyst bed is 360, 395, 440, 490, 550, and 1030 mm from top to bottom. The upper and lower ceramic ball layers are made of inert alumina ceramic balls. The thickness is 150mm. There are 5 pipe-type gas distributors between sections, the diameter of the main pipe is φ70, 6 branch pipes, the diameter is φ40, and the number of openings is 50. The opening diameters of the 5 pipe-type gas distributors are 3.5, 4, 4, 4.5, 5 mm, the angle between holes is 6...

Embodiment 3

[0031] The 160,000 tons / year ethylbenzene unit of a factory adopts molecular sieve gas-phase alkylation process. The alkylation reactor is a 6-stage layered adiabatic fixed-bed reactor with an inner diameter of φ1600 and an inner diameter of the inlet pipe d in =500 mm, adopt the conical single-stage baffle type inlet gas pre-distributor as shown in Figure 3, and its cylinder inner diameter d i =470mm, cone angle α=150°, ring gap height H=120mm. The height of the homogenization space inside the reactor is 2250mm, and the height of the catalyst bed is 280, 310, 350, 395, 440, 815mm from top to bottom. The upper and lower ceramic ball layers are made of inert alumina ceramic balls. The thicknesses are 210 and 170 mm respectively. There are 5 inter-stage calandria gas distributors, the diameter of the main pipe is φ150, 12 branch pipes, the diameter is φ50, and the number of openings is 196. The opening diameters of the 5 calandria gas distributors are 4, 4.5, 5, 5.5, 6 mm, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com