Method for producing heat-insulating fire-proofing material of calcium silicate by pouring-shaping

A fireproof material, casting molding technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of heat-resistant temperature not exceeding 650 ℃, waste of water resources and energy, not exceeding 650 ℃, etc. The effect of less amount and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

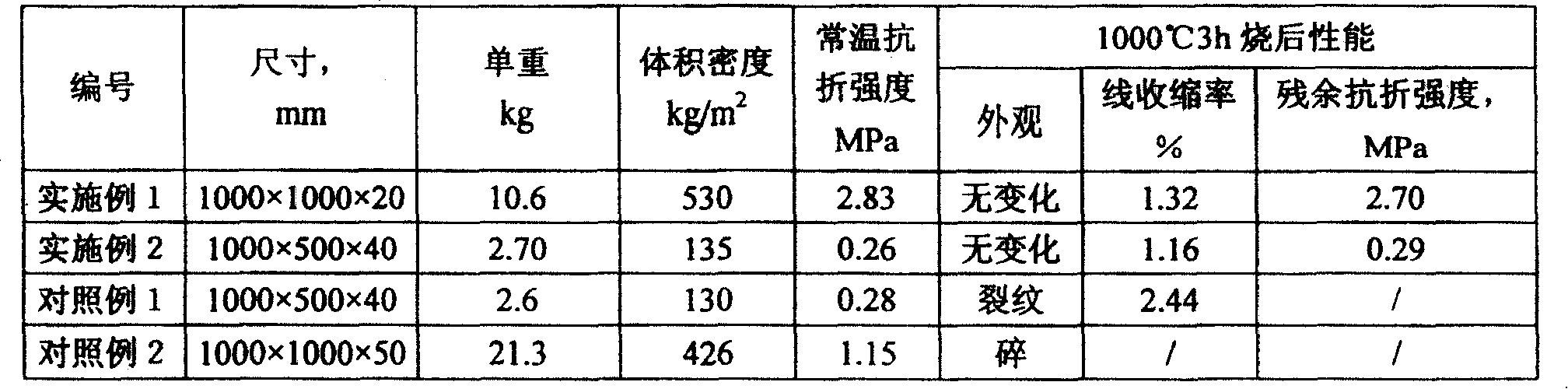

[0035] Grind the quartz powder until all of it passes through a multi-hole sieve, add slaked lime powder with a CaO content of 72.2%, stir well, the C / S of the slurry=0.99, then add 6% cotton fiber and 4% wollastonite powder by dry weight, Stir well, pour it into a mold of 1010×1010×400 (length×width×height, mm), put the mold and trolley with materials into the steam curing kettle, heat it to 1.8MPa with steam, and keep it between 1.8~2.0MPa Continue for 24 hours, cool down to normal pressure, take out the kettle, open the mold, dry the block to constant weight in a drying kiln at about 140°C, cut it into 1010×1010×21 (mm) boards with a diamond saw, and then It is processed into finished boards of 1000×1000×20 (mm) by sanding machine and trimming machine. Other related properties are shown in Table 1.

Embodiment 2

[0037] Grind the quartz powder until it passes through a million-hole sieve (0.061 mm), add the dispersed silica fume, the weight ratio of quartz and silica fume is 6:4, add lime milk with a CaO content of 73.1% (dry basis), and stir well. The C / S of the slurry is 1.03, then add 3% paper fiber and 12% wollastonite powder in dry weight, stir well, pump into the gelling tank with stirring, heat to 130-140°C with steam and last for 20 hours, and then cooled down to normal pressure. Inject the slurry into a mold of 1010×1010×400 (mm), put it into the kettle, and continue for 16 hours under the pressure of 2.3-2.5MPa, cool down and leave the kettle, open the mold, dry, slice, sand, trim, and process into 1000×500×40 (mm) plate. Other properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com