Copper-manganese based prealloy powder for metal-diamond soldering, and its prodn. method

A technology of pre-alloyed powder and pre-alloyed powder, applied in the field of pre-alloyed powder and its preparation, can solve the problems of increasing the degree of thermal damage of diamond, damaged mechanical properties and toughness, high price, etc. Good antioxidant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

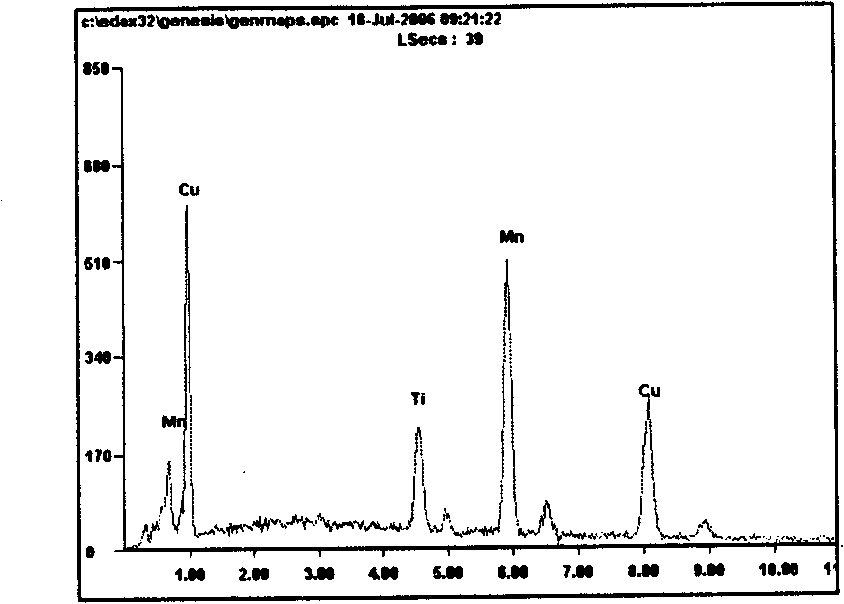

[0027] The copper-manganese-based pre-alloy powder for metal-diamond brazing in this embodiment is made of the following components by weight percentage: Cu 60%, Mn 31.7%, Ti 8%, La 0.3%.

[0028] The preparation method of the pre-alloyed powder of the present embodiment is carried out in the following steps:

[0029] (1) Take the ingredients according to the above proportioning ratio, and place them in the smelting furnace;

[0030] (2) Under the condition of vacuum degree of 10MPa, heat to 1200°C to melt the ingredients;

[0031] (3) Fill the powder collector with 6m 3 The purity is 99.999% high-purity argon;

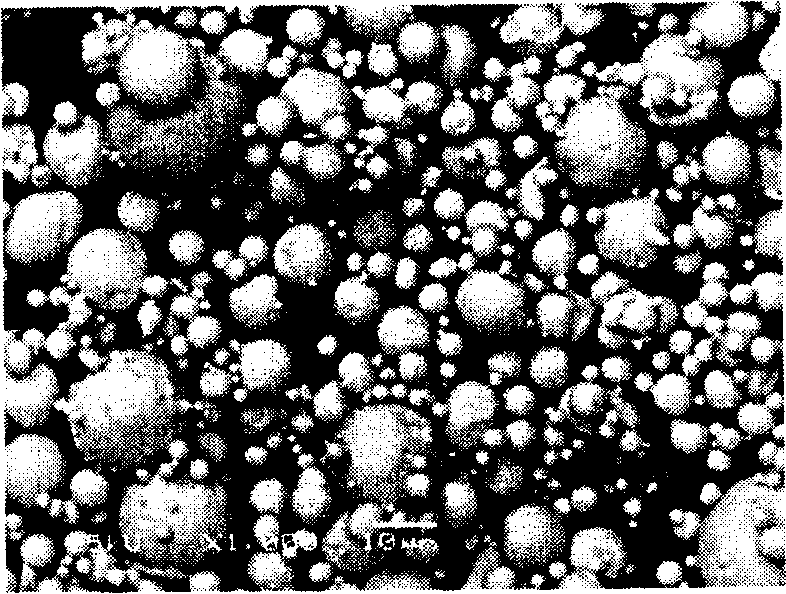

[0032] (4) Pour the melted ingredients into a thermal insulation leak bag with a temperature of 1300°C, use high-purity argon as the atomizing gas, atomize the above-mentioned melted ingredients through the atomizing nozzle, and form powder in the powder collector , the atomizing gas pressure is 4MPa, the particle size of the obtained pre-alloyed powder is less tha...

Embodiment 2

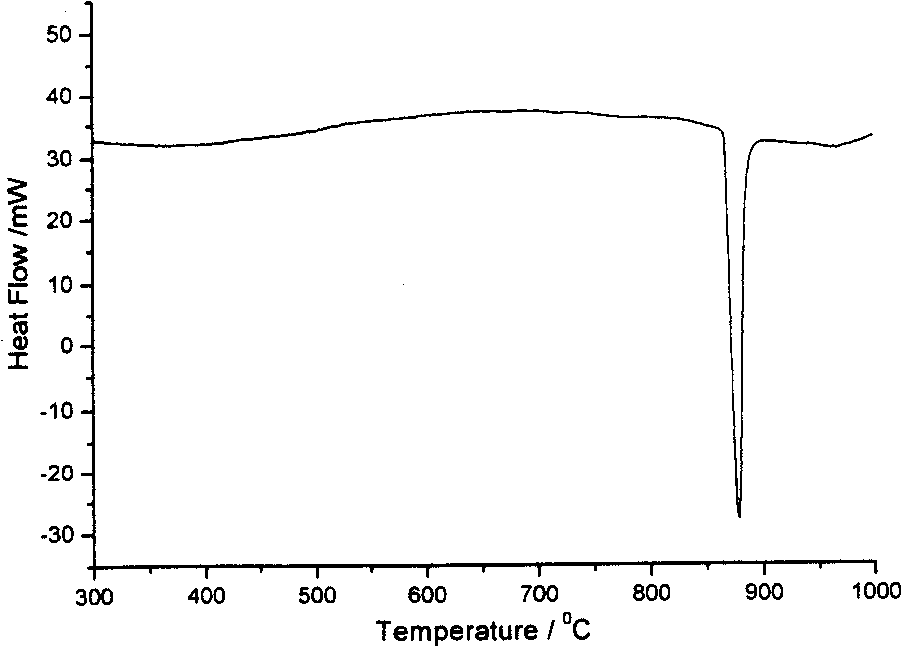

[0034] The preparation steps are the same as in Example 1, except that the weight percentage of each component is changed: Cu 62%, Mn32.9%, Ti 5%, La 0.1%, appended Figure 4 It is shown that the melting point of the pre-alloyed powder of this embodiment is between 850-880°C.

Embodiment 3

[0036] The preparation steps are the same as in Example 1, only changing the weight percentage of each component: Cu 58.6%, Mn31.2%, Ti 10%, La 0.2%, with Figure 5 It is shown that the melting point of the pre-alloyed powder of this embodiment is between 860-880°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com