Samarium-iron-nitrogen and iron-platinum double phase nano magnetic material and its preparing method

A nano-magnetic material, samarium-iron-nitrogen technology, applied in the direction of magnetism of inorganic materials, can solve the problems of no magnetic performance, no exchange coupling effect, etc., and achieve the effect of easy operation, simple equipment and high magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

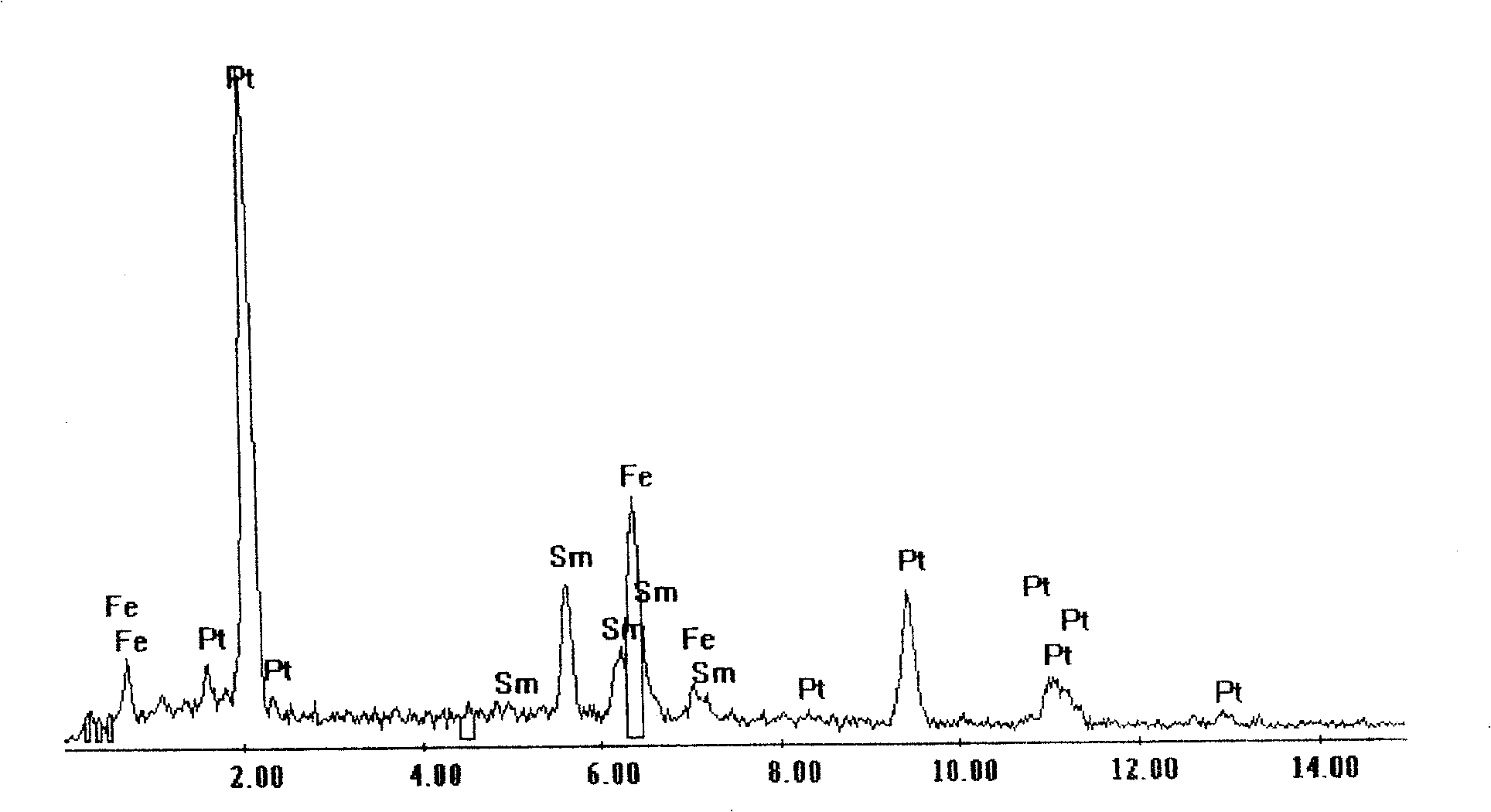

[0033] (1) Melting of master alloy

[0034] Use iron, samarium, and platinum with a purity greater than 99.9% as raw materials, and the mass ratio is Sm:Fe:Pt=10:86:4. The raw materials that are batched according to the ratio are placed in a non-consumable vacuum electric arc furnace, also known as a button furnace. The master alloy was melted under the protection of pure argon, smelted twice, each time for 3 minutes, and the current was 50A, and the iron samarium platinum master alloy Sm was obtained. 10 Fe 85 Pt 1 .

[0035] (2) Alloy throwing belt

[0036] Put the iron samarium-platinum master alloy prepared in step (1) into a quartz tube, place the quartz tube in the high-frequency induction coil in the cavity of the vacuum single-roller melt stripping machine, the bottom of the quartz tube is away from the copper roller The distance between them is 2mm, and argon gas is introduced to control the pressure difference Δp between the gas storage pressure tank and the cavi...

Embodiment 2

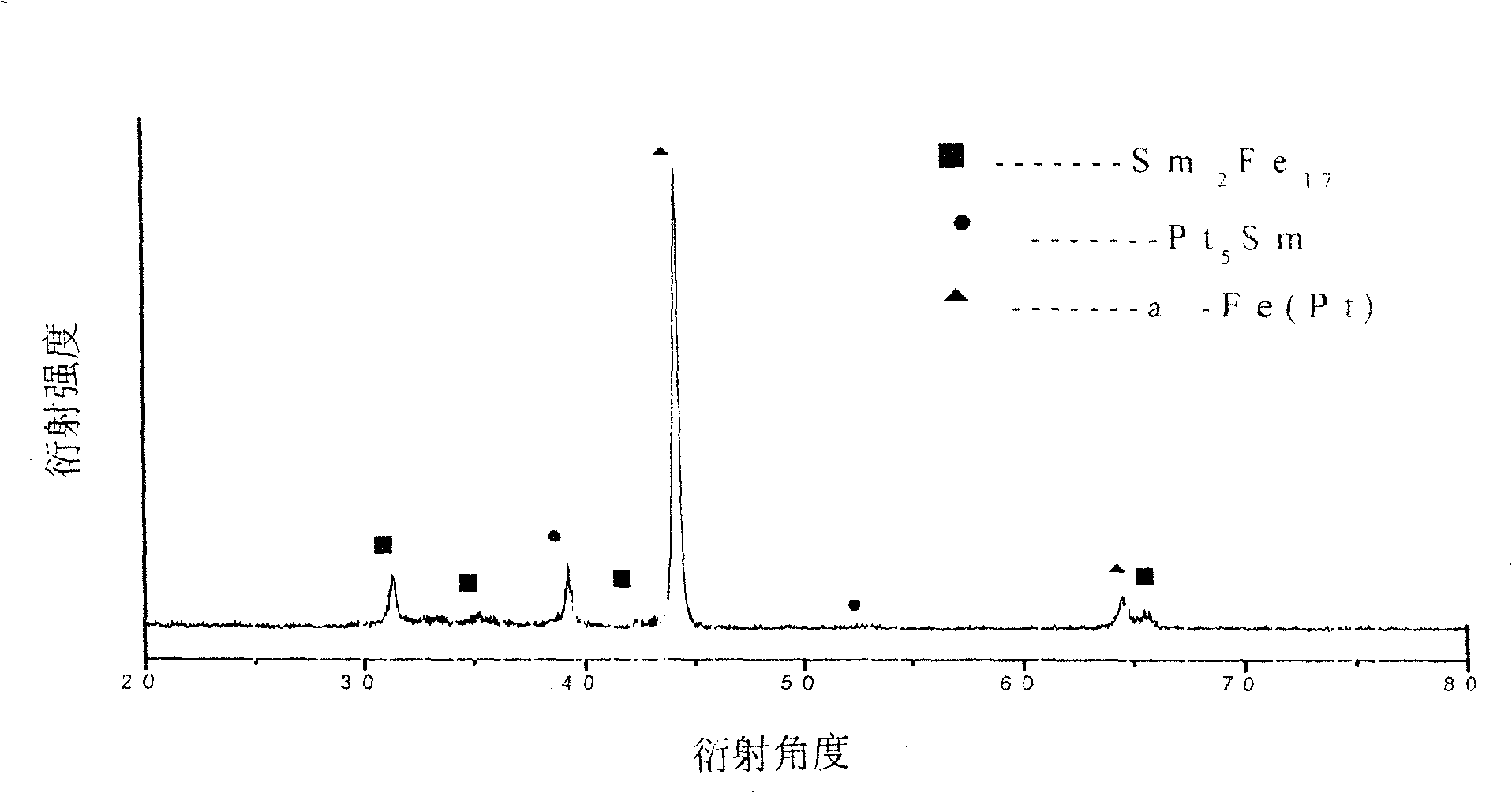

[0042] Except that step (3) was carried out at 800° C. for crystallization, the others were the same as in Example 1. Thus, Sm with grain size d≤30nm is obtained 2 Fe 17 N 3 -Fe 3 Pt dual-phase nano-magnetic material, the magnetic performance test results are shown in Table 1.

Embodiment 3

[0044] (1) Melting of master alloy

[0045] Use iron, samarium, and platinum with a purity greater than 99.9% as raw materials, and the mass ratio is Sm:Fe:Pt=9:85:6. The raw materials that are batched according to the ratio are placed in a non-consumable vacuum electric arc furnace, also known as a button furnace. Melt the master alloy under the protection of pure argon, smelt 3 times, each time for 2 minutes, and the current is 180A, and obtain the iron samarium platinum master alloy Sm 9 Fe 85 Pt 6 ;

[0046] (2) Alloy throwing belt

[0047] Put the iron samarium-platinum master alloy prepared in step (1) into a quartz tube, place the quartz tube in the high-frequency induction coil in the cavity of the vacuum single-roller melt stripping machine, the bottom of the quartz tube is away from the copper roller The distance between them is 3.5mm, and argon is introduced to control the pressure difference Δp between the gas storage pressure tank and the cavity of the strip m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com