Bainite ductile iron grinding ball and its producing process

A technology of nodular cast iron and bainite, applied in the field of bainite nodular cast iron grinding balls and its production process, can solve the problems of easy pollution of the quenching medium, high production cost, unstable quality, etc., and achieve large-scale industrial production , Improve the performance of the grinding ball, and the production process is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Smelting in an intermediate frequency induction furnace to obtain ductile iron with the following mass ratio (wt.%): C 3.4%; Si 3.1%; Mn 3.0%; Mg 0.05%; Re 0.05%; P≤0.1%; S≤0.04 %; the rest is Fe. Before being released from the furnace, a rare earth ferrosilicon-magnesium alloy is added as a nodulizer according to 1.5% of the mass of molten iron, and then a ferrosilicon alloy with a mass ratio of 75% is added as an inoculant according to 1% of the molten iron mass, and the temperature of the molten iron is controlled at 1450-1480 ℃;

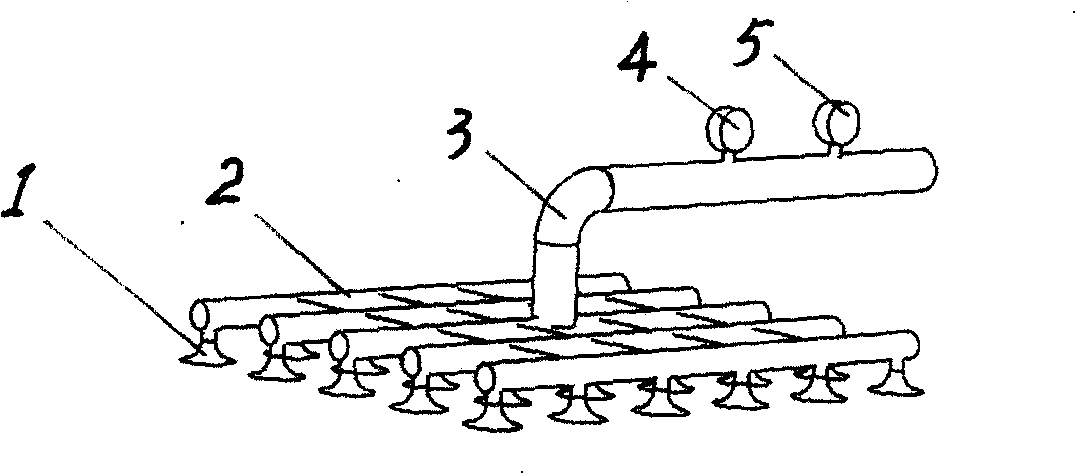

[0031] (2) The molten iron in step (1) is cast into shape according to the following method: the casting of the grinding ball adopts vacuum solid mold casting (EPC). First bond the shape of the grinding balls into strings, then coat with EPC special paint about 1mm thick, bake at 50-60℃ for 2-4 hours; when modeling, first put the sand box on the vibration table, fill Put in the bottom sand, after vibrating for 30s, scrape the bottom ...

Embodiment 2

[0039] (1) Smelting in an intermediate frequency induction furnace to obtain ductile iron with the following mass ratio (wt.%): C 3.8%; Si 2.8%; Mn 3.3%; Mg 0.03%; Re 0.03%; P≤0.1%; S≤0.04 %; the rest is Fe. Melting process is identical with embodiment 1;

[0040] (2) casting process is identical with embodiment 1, and the diameter of prepared grinding ball is 100mm;

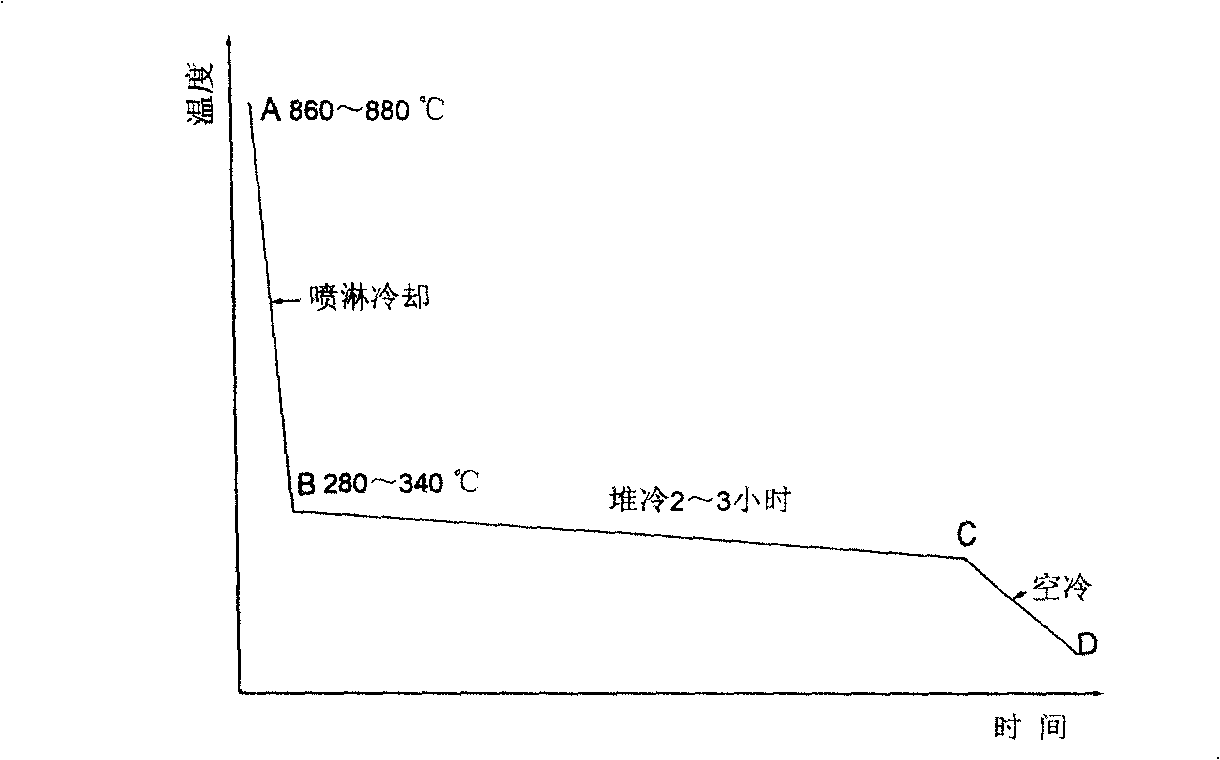

[0041] (3) Perform the following heat treatment on the cast ductile iron grinding ball:

[0042] a. Heat the grinding ball to the austenite zone, select the temperature as 880°C, and keep it warm for 2 hours;

[0043] b. Atomize the water, then spray it continuously on the ball for cooling, and control the pressure of the water flow to 0.16MPa, until the temperature of the ball reaches 280°C, stop spraying;

[0044] c. Pile the spray-cooled grinding balls in a closed container, and use the waste heat of the grinding balls to keep warm for 3 hours;

[0045] d. Take the grinding ball out of the container and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com