Preparation method of phospholipid functional photoluminous reinforced type nuclear shell structure quantum point

A core-shell structure, photoluminescence technology, applied in the field of composite materials, can solve the problems of no biological and chemical stability, no stable chemical bond connection, etc., achieve good colloidal stability, enhance photoluminescence performance, and have wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

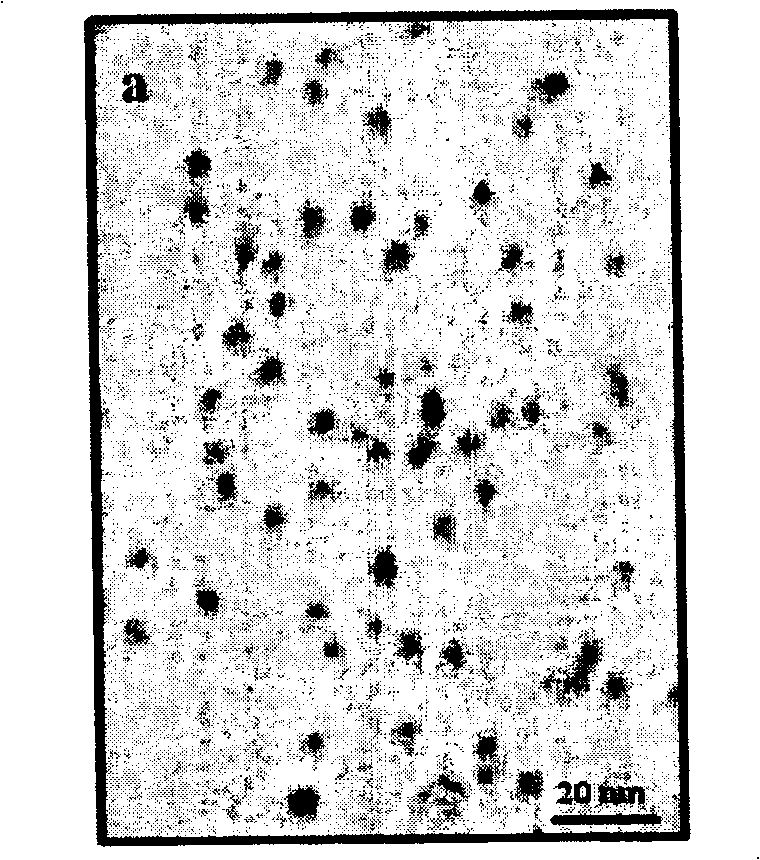

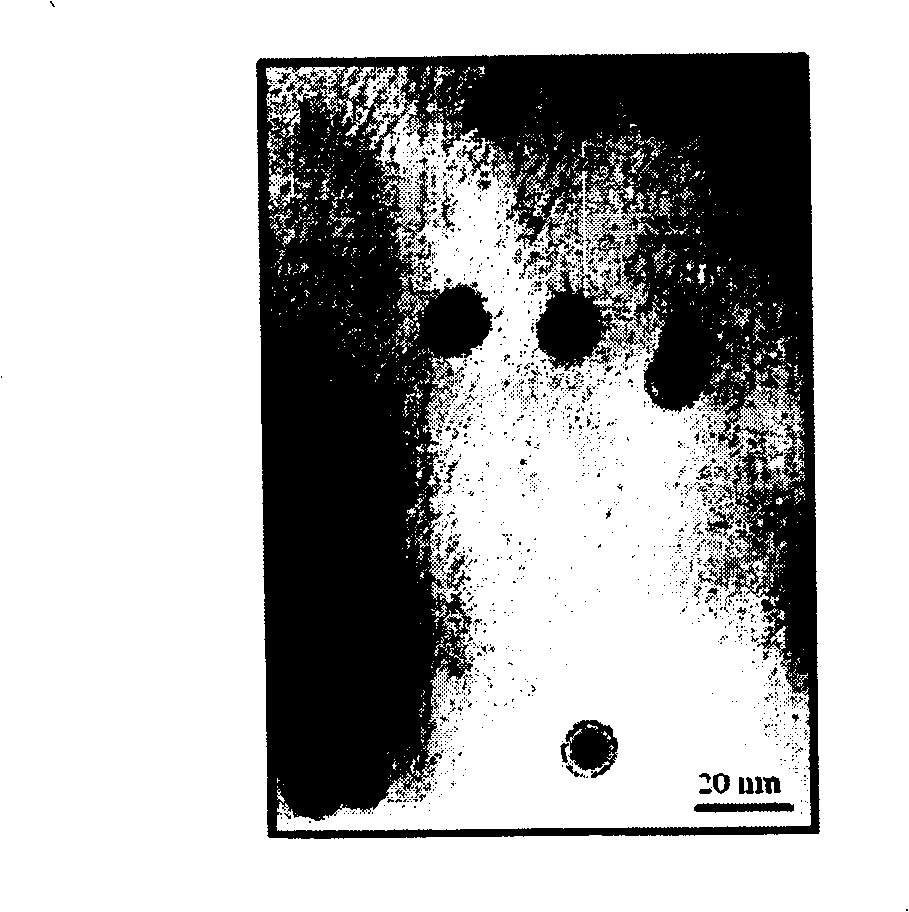

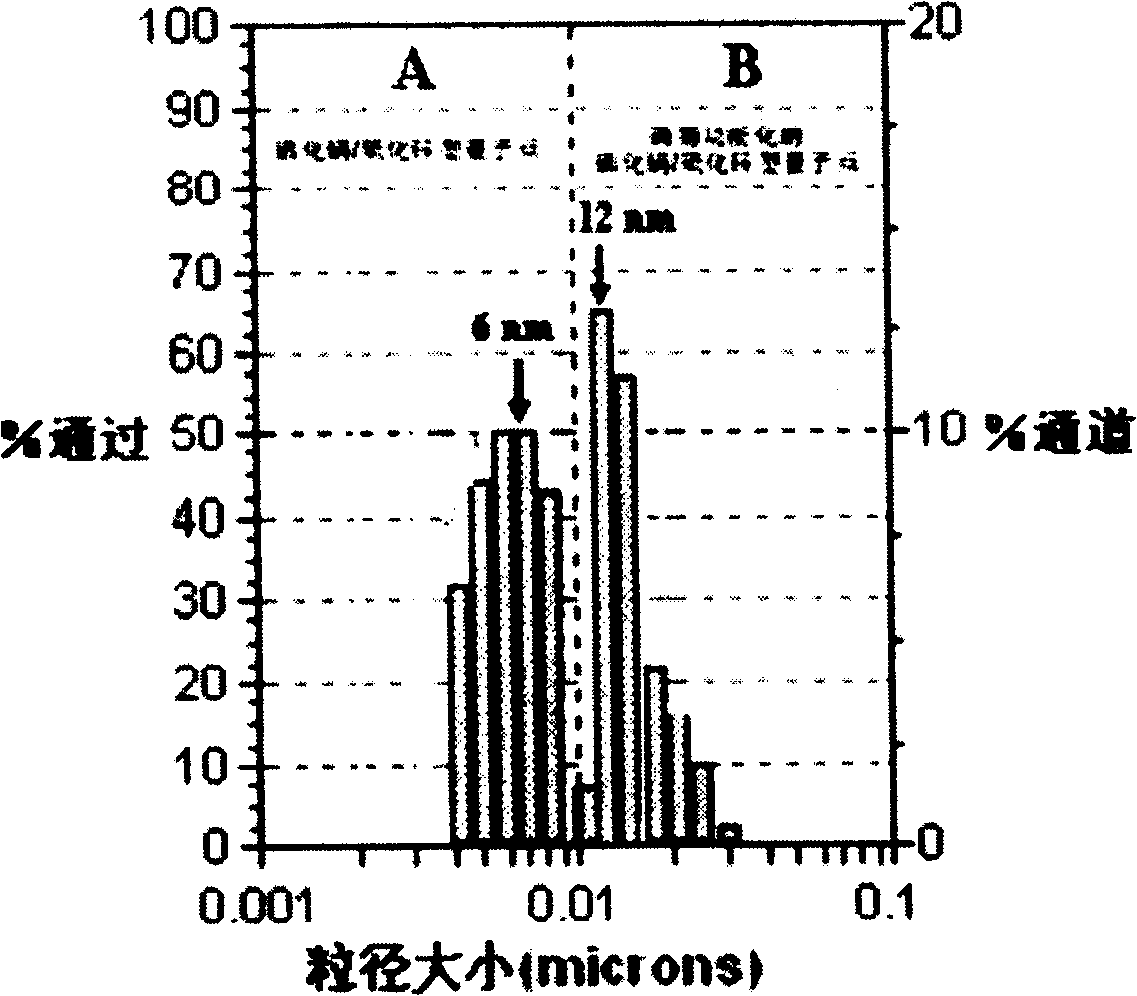

[0027] Using cadmium oxide, selenium, dimethyl zinc and bistrimethyl silicon sulfide as the initial raw materials, cadmium selenide / zinc sulfide type core-shell structure quantum dots are formed after solution cooling and crystallization at high temperature, and then react with phospholipids with mercapto groups, through The interaction between zinc and sulfur to prepare phospholipid-functionalized photoluminescence-enhanced core-shell quantum dots.

[0028] Step a: Add 0.0615 grams of cadmium oxide, 0.2211 grams of tetradecyl phosphonic acid and 3.7750 grams of trioctylphosphine oxide in a 25 ml flask, seal and feed into argon for protection, heat to 320 degrees Celsius, let the cadmium oxide Fully melt in the mixed solution of tetraalkylphosphonic acid and trioctylphosphine oxide.

[0029] Step b: reduce the temperature of the reaction system to 270 degrees centigrade, add sulfur, selenium or tellurium stock solution in the flask (this solution is that 0.0609 grams of powder...

Embodiment 2

[0035] Using cadmium oxide, selenium, dimethyl zinc and bistrimethyl silicon sulfide as the initial raw materials, cadmium selenide / zinc sulfide type core-shell structure quantum dots are formed after solution cooling and crystallization at high temperature, and then react with phospholipids with mercapto groups, through The interaction between zinc and sulfur to prepare phospholipid-functionalized photoluminescence-enhanced core-shell quantum dots.

[0036] Step a: Add 0.01 gram of cadmium oxide, 0.01 gram of tetradecyl phosphonic acid and 0.01 gram of trioctylphosphine oxide in a 25 ml flask, seal it, feed it with argon for protection, heat to 320 degrees Celsius, and let the cadmium oxide Fully melt in the mixed solution of tetraalkylphosphonic acid and trioctylphosphine oxide.

[0037] Step b: reduce the temperature of the reaction system to 270 degrees centigrade, add sulfur, selenium or tellurium stock solution in the flask (this solution is to dissolve the powder of one...

Embodiment 3

[0043] Using cadmium oxide, selenium, dimethyl zinc and bistrimethyl silicon sulfide as the initial raw materials, cadmium selenide / zinc sulfide type core-shell structure quantum dots are formed after solution cooling and crystallization at high temperature, and then react with phospholipids with mercapto groups, through The interaction between zinc and sulfur to prepare phospholipid-functionalized photoluminescence-enhanced core-shell quantum dots.

[0044] Step a: add 1 gram of cadmium oxide, 1 gram of tetradecyl phosphonic acid and 10 grams of trioctylphosphine oxide in a 25 ml flask, seal and feed into argon for protection, heat to 320 degrees Celsius, let cadmium oxide Fully melt in the mixed solution of tetraalkylphosphonic acid and trioctylphosphine oxide.

[0045] Step b: reduce the temperature of the reaction system to 270 degrees Celsius, add sulfur, selenium or tellurium stock solution in the flask (this solution is to dissolve 1 gram of powder of one of the three n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com