Stepped scanning photoetching machine vibration isolation system analoy experimental apparatus

A vibration isolation system and simulation test technology, which is applied in photoplate-making process exposure devices, microlithography exposure equipment, optics, etc. The effect of engraving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

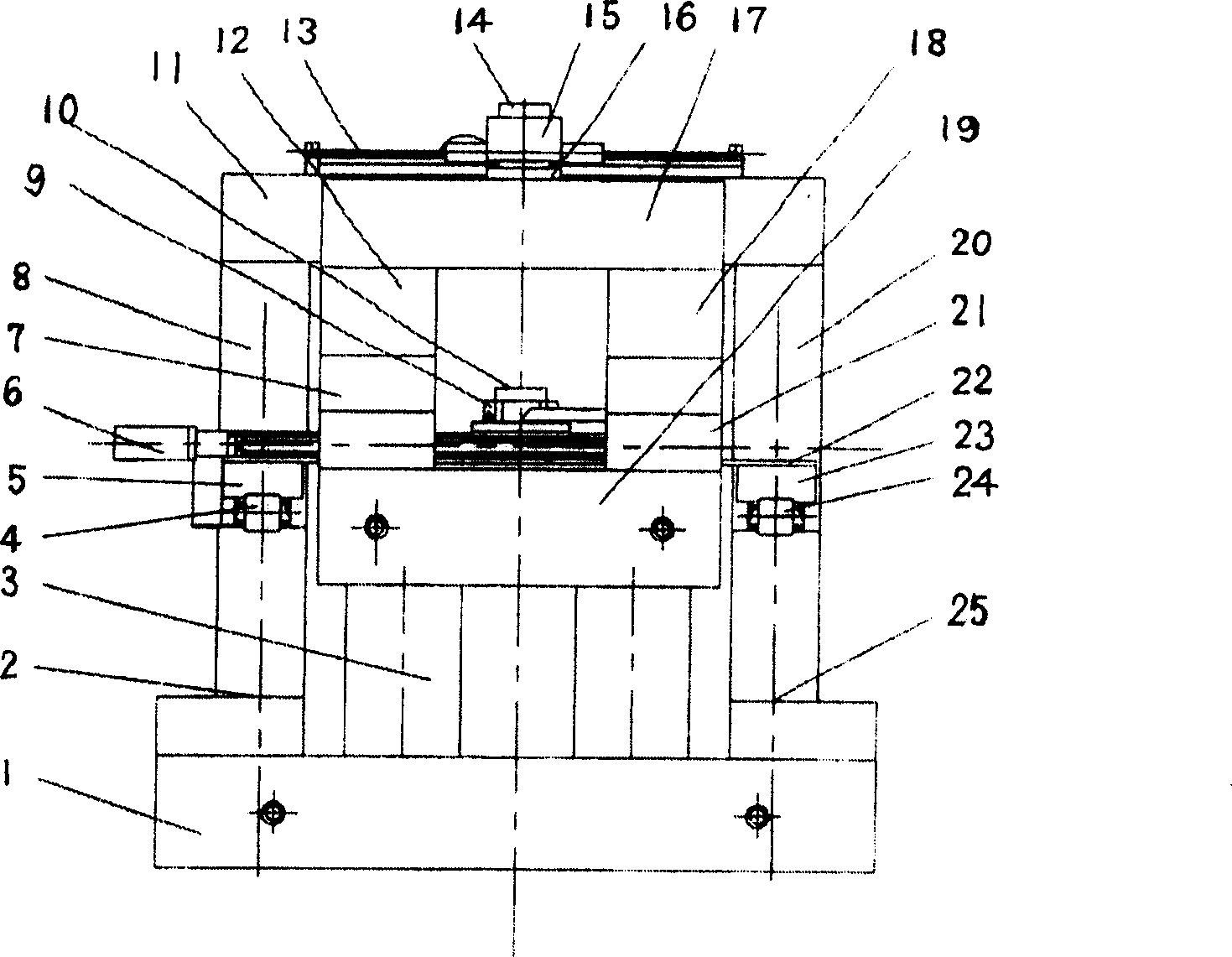

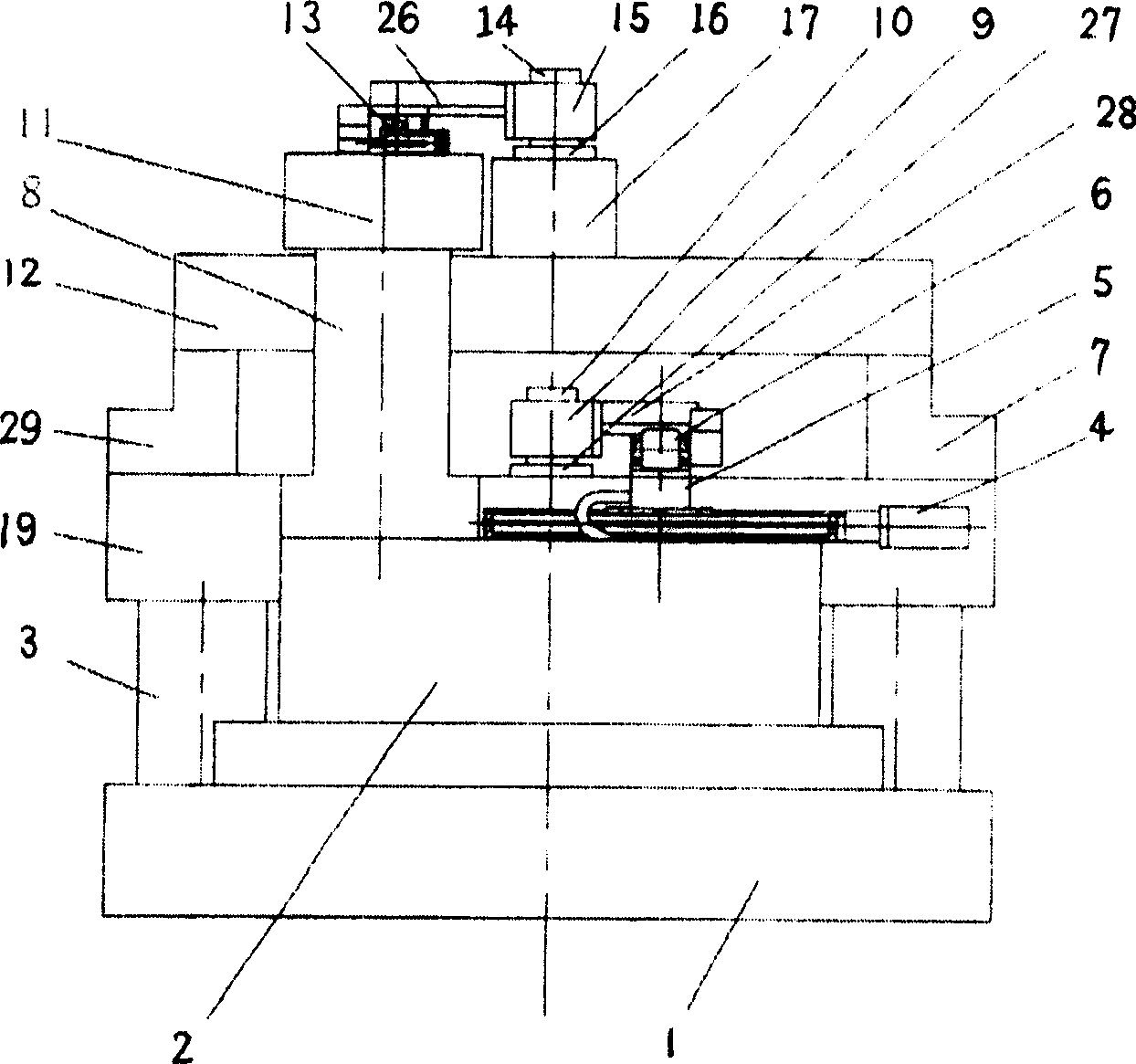

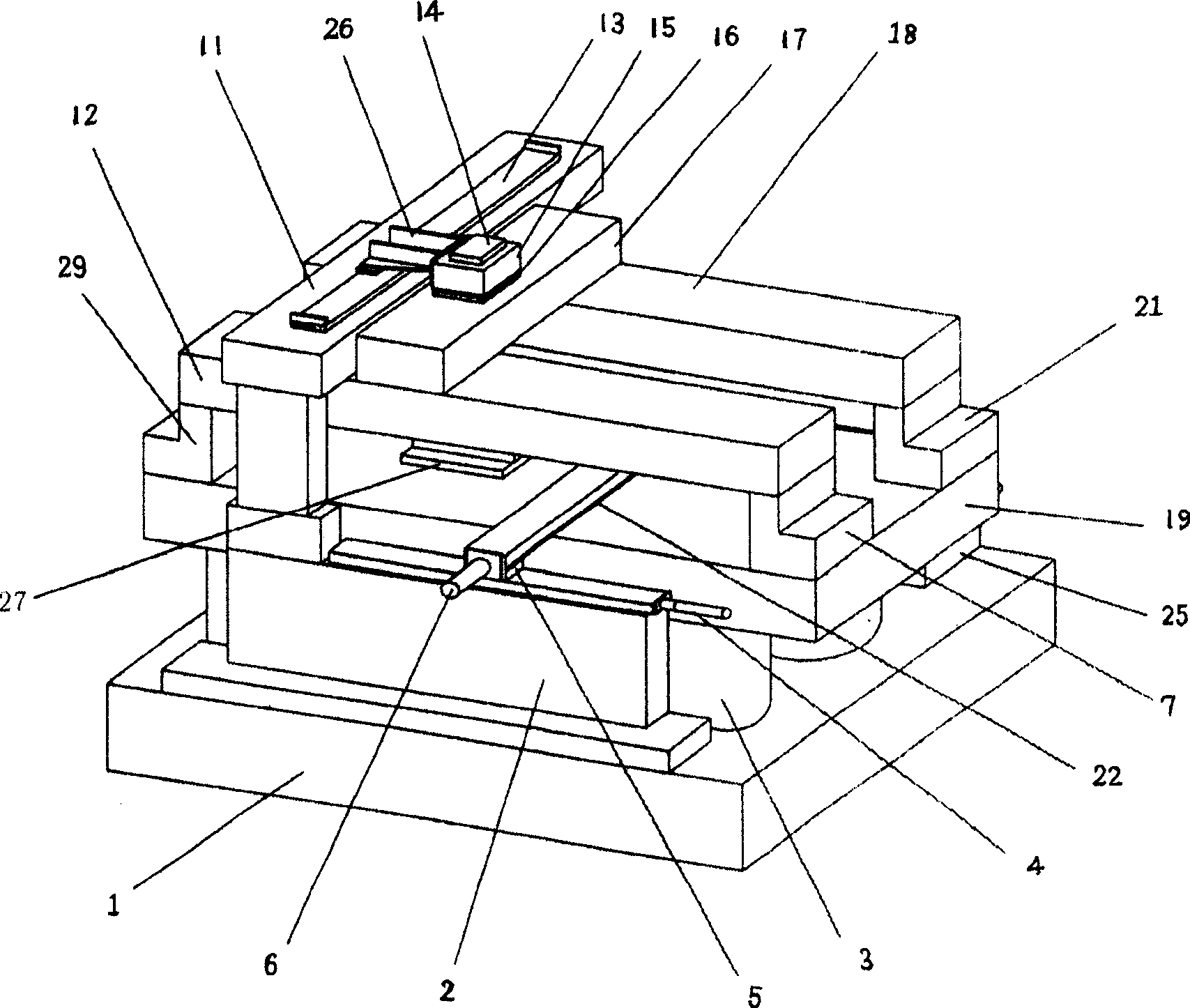

[0019] see figure 1 , figure 2 and image 3 , on the base 1, the lower left column 2 and the lower right column 25 are fixedly installed by screws, and the XA positioning platform 4 and the XB positioning platform 24 are respectively installed on one end of the upper surface of the lower left column 2 and the lower right column 25 by screws. 2 and the other end of the upper surface of the lower right column 25 are respectively equipped with the upper left column 8 and the upper right column 20 by screws, and the two ends of the linear motor mounting base 11 are respectively fixed on the upper surface of the upper left column 8 and the upper right column 20 by screws. The device 3 is installed on the upper surface of the base 1, the working platform 19 is directly on the upper surface of the four shock absorbers 3, the left front mask table column 7, the left rear mask table column 29, the right front mask table column 21, the right rear mask table The mold table column is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com