Preparation method for carbon nano-tube enhanced aluminum nitride composite material

A carbon nanotube and composite material technology, which is applied in the field of composite material preparation, can solve the problems of high synthesis cost of aluminum nitride ceramic powder, difficult low-temperature densification and sintering, insufficient mechanical properties, etc., to solve the problem of carbon nanotube dispersion and Effects of low temperature sintering, lower sintering temperature, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

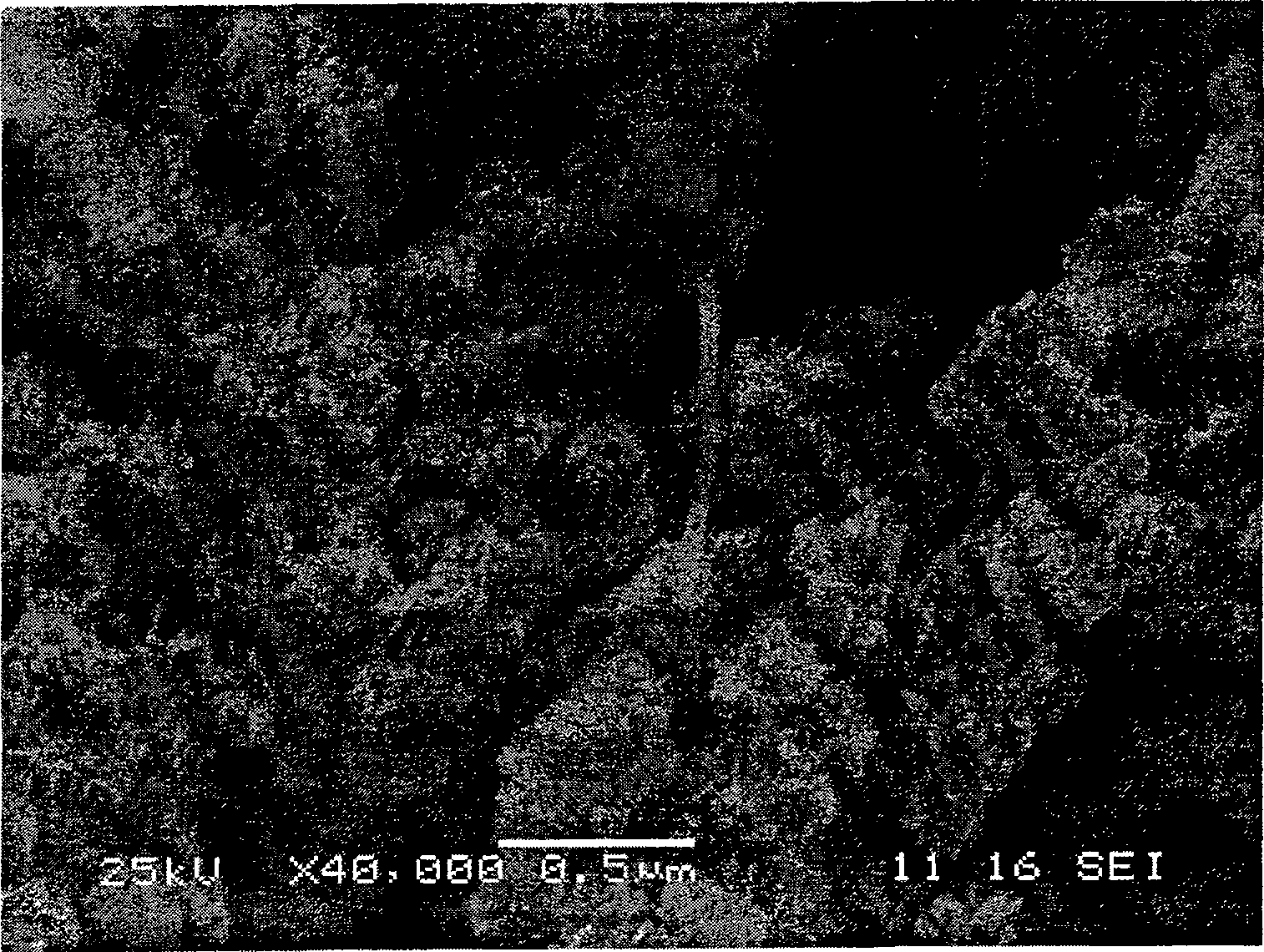

[0026] Embodiment 1: the preparation of CNTs (1wt%) / AlN composite material

[0027] 1. Chemical purification of carbon nanotubes: the multi-walled carbon nanotubes with a diameter of 20 to 40 nm, a length of 5 to 15 μm and a purity of 95% are placed in sodium hydroxide ( NaOH) solution for 1 hour, filtered, washed with distilled water and dried; then the dried carbon nanotubes were placed in nitric acid (HNO 3 ) solution for 1 hour, washed with distilled water and dried to obtain purified carbon nanotubes. (The sodium hydroxide solution can be replaced by sodium carbonate solution or ammonia water, and the nitric acid solution can be replaced by sulfuric acid.)

[0028] 2. Ultrasonic dispersion of carbon nanotubes: place the purified carbon nanotubes in absolute ethanol, which contains 2 wt% dispersant triton in the absolute ethanol, and ultrasonically disperse them for 12 hours using an ultrasonic cleaner. The dispersed carbon nanotubes are obtained. The dispersant may als...

Embodiment 2

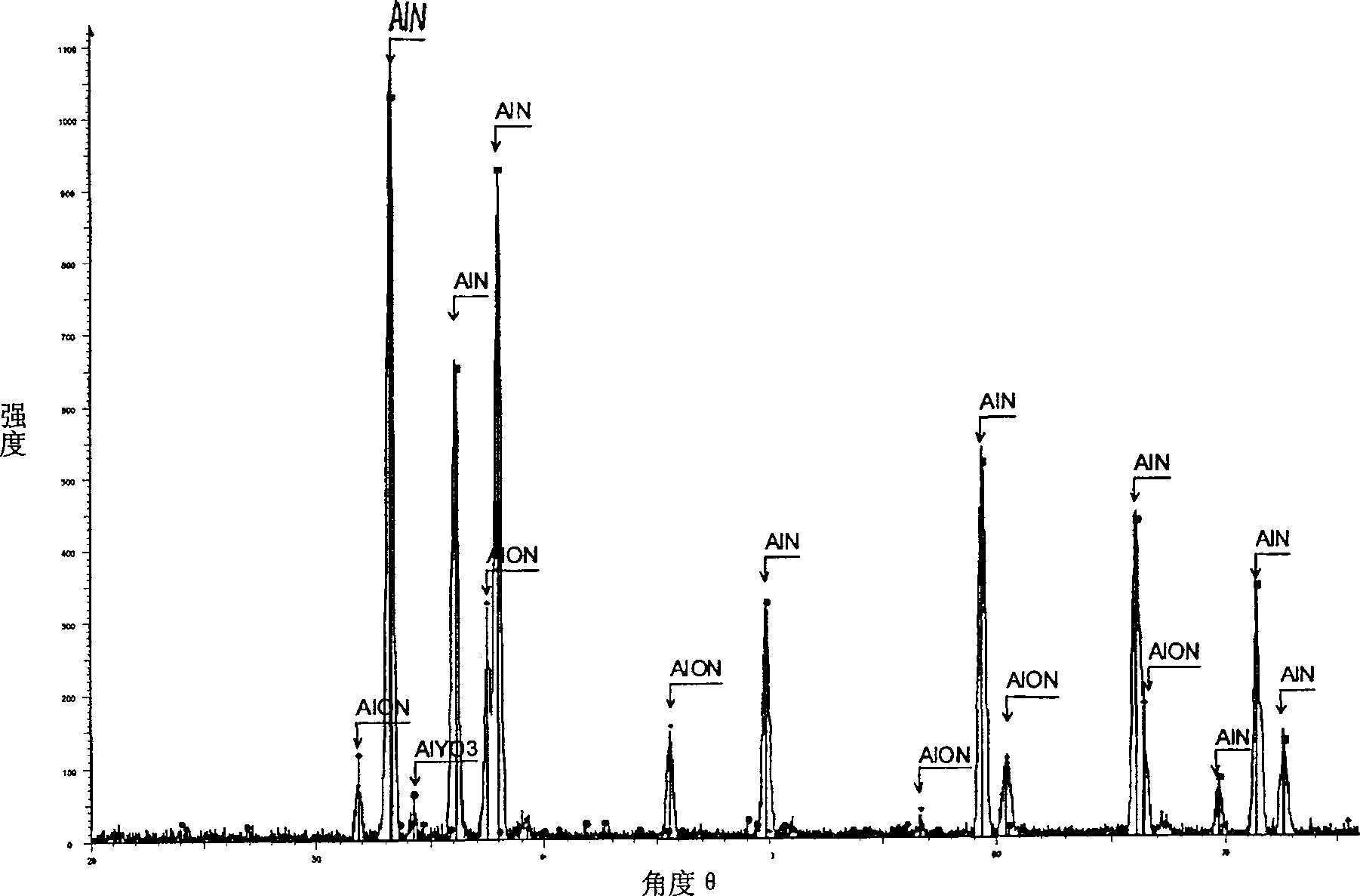

[0034] Embodiment 2: the preparation of CNTs (3wt%) / AlN composite material

[0035]1. Chemical purification of carbon nanotubes: the multi-walled carbon nanotubes with a diameter of 20 to 40 nm, a length of 5 to 15 μm and a purity of 95% are placed in a sodium hydroxide solution with a concentration of 4mol / L and a temperature of 80°C ( NaOH) for 1 hour, filtered, washed with distilled water and dried; then the dried carbon nanotubes were placed in a nitric acid solution (HNO 3 ) for 1 hour, washed with distilled water and dried to obtain purified carbon nanotubes.

[0036] 2. Ultrasonic dispersion of carbon nanotubes: place the purified carbon nanotubes in absolute ethanol, which contains a dispersant triton with a mass percentage of 2wt%, and use an ultrasonic cleaner to ultrasonically disperse for 12 hours to obtain dispersed carbon nanotubes.

[0037] 3. Mixing and ball milling dispersion: Take 18.6g of aluminum nitride, 0.4g of yttrium oxide, 0.4g of calcium fluoride an...

Embodiment 3

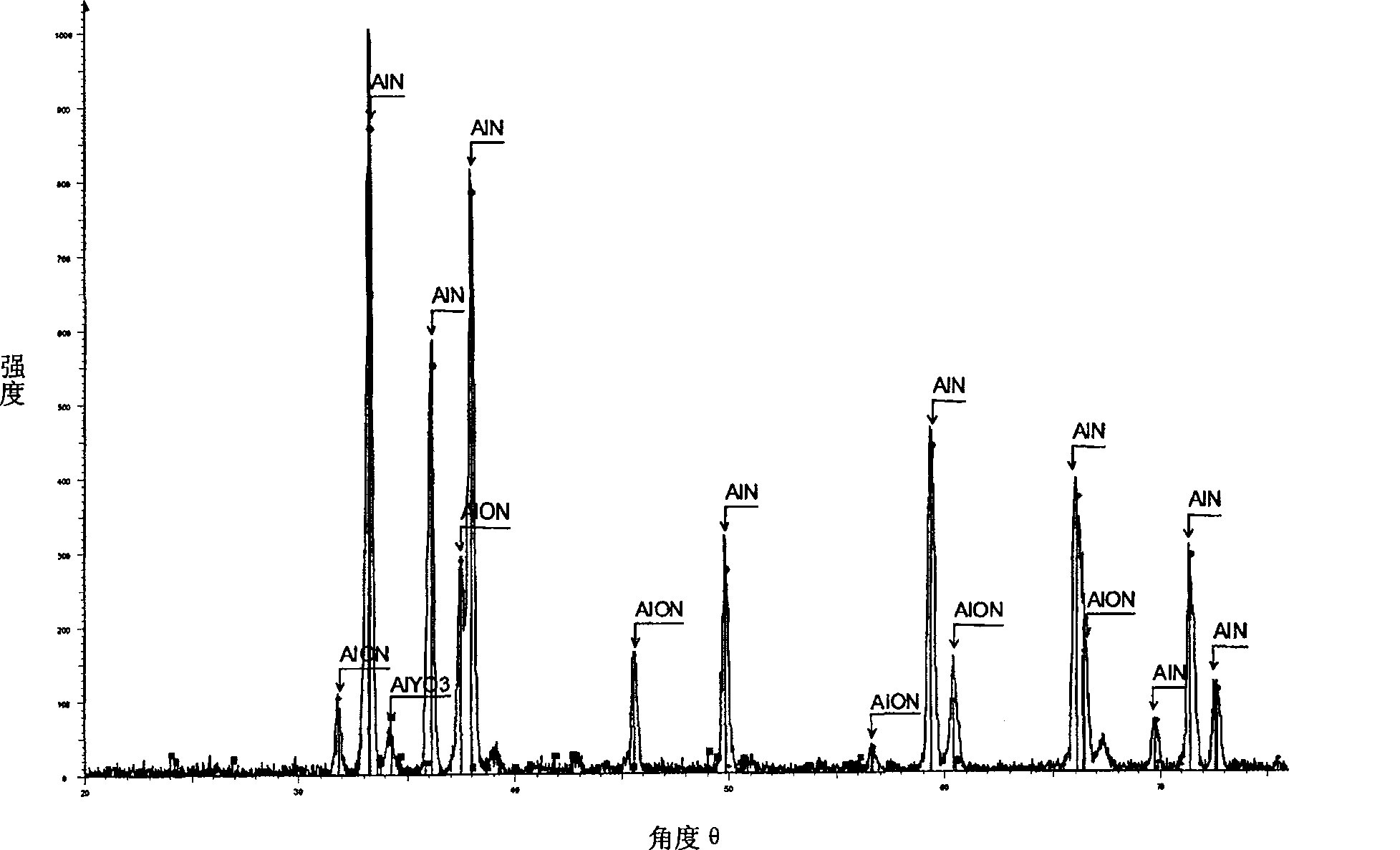

[0042] Embodiment 3: the bulk preparation of CNTs (3wt%) / AlN composite material

[0043] 1. Chemical purification of carbon nanotubes: the multi-walled carbon nanotubes with a diameter of 20 to 40 nm, a length of 5 to 15 μm and a purity of 95% are placed in a sodium hydroxide solution with a concentration of 4mol / L and a temperature of 80°C ( NaOH) for 1 hour, filtered, washed with distilled water and dried; then the dried carbon nanotubes were placed in a nitric acid solution (HNO 3 ) for 1 hour, washed with distilled water and dried to obtain purified carbon nanotubes.

[0044] 2. Ultrasonic dispersion of carbon nanotubes: place the purified carbon nanotubes in absolute ethanol, which contains a mass percentage of 2wt% dispersant triton, and use an ultrasonic cleaner to ultrasonically disperse for 12 hours to obtain a dispersed after carbon nanotubes.

[0045] 3. Mixing ball mill dispersion: take 18.6kg of raw materials aluminum nitride, 0.4kg of yttrium oxide, 0.4kg of ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com