Rare earth hydroxide catalyst for moderate/low temperature carbonyl sulfur hydrolysis and preparation method thereof

A rare earth hydroxide and catalyst technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of decreased activity, low COS content and space velocity of raw gas, and need for regular regeneration, and achieves medium and low temperature. The effect of high activity, simple preparation method and large operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh La 2 o 3 Add 100ml of deionized water to 10g of the sample, hydrothermally treat it at 95°C for 2.5 hours until it becomes colloidal, let it stand for 2 hours, then dry it at 110°C for 24 hours, press into tablets and sieve to take a lanthanum hydroxide sample of 40-60 mesh;

[0030] (2) Install lanthanum hydroxide in a fixed bed quartz reactor (Φ8 x 300mm) at a temperature of 100°C and a space velocity of 5,000hr -1 , COS conversion rate is 94% under the condition of COS content 150ppm.

Embodiment 2

[0032] (1) Take 0.25g of KOH sample and dissolve it in 30ml deionized water, add the KOH solution to the La(OH) prepared in Example 1 3 In the colloid, stir for 2 hours, let stand for 2 hours, then dry at 120°C for 24 hours, take a 40-60 mesh sample after tableting and sieving;

[0033] (2) The two-component catalyst is installed in the reactor as described in Example 1, at a temperature of 80° C. and a space velocity of 5,000 hr -1 , under the condition of COS content 150ppm, the conversion rate of COS is 92.2%.

Embodiment 3

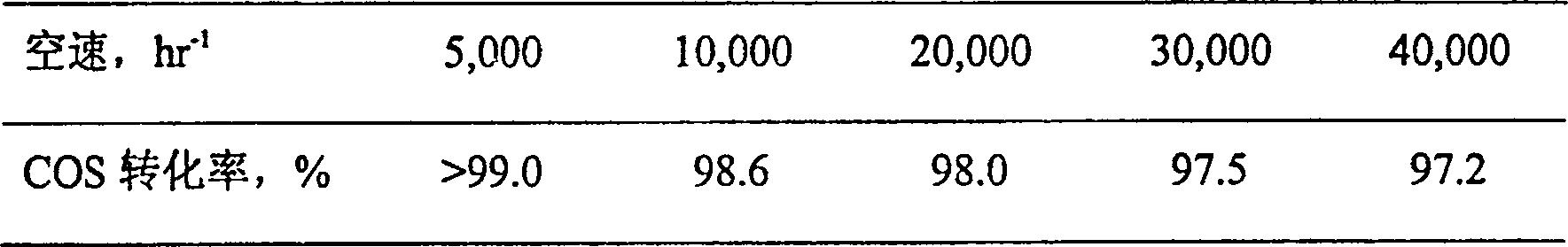

[0035] Get the La(OH) prepared by embodiment 1 3 , at a temperature of 125°C and a space velocity of 5,000-40,000hr -1 , COS conversion rate is shown in Table 1 under the condition of COS content 150ppm:

[0036] Table 1 Space velocity versus La(OH) 3 Effect of Catalyst on COS Hydrolysis Activity

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com