Nanometer oxide porous membrane electrode and preparing method and application thereof

A nano-oxide and porous film technology, applied in capacitor electrodes, circuits, photovoltaic power generation, etc., can solve the problems of energy consumption, time-consuming, unusable, etc., and achieve the effect of uniform film layer, simple preparation process and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

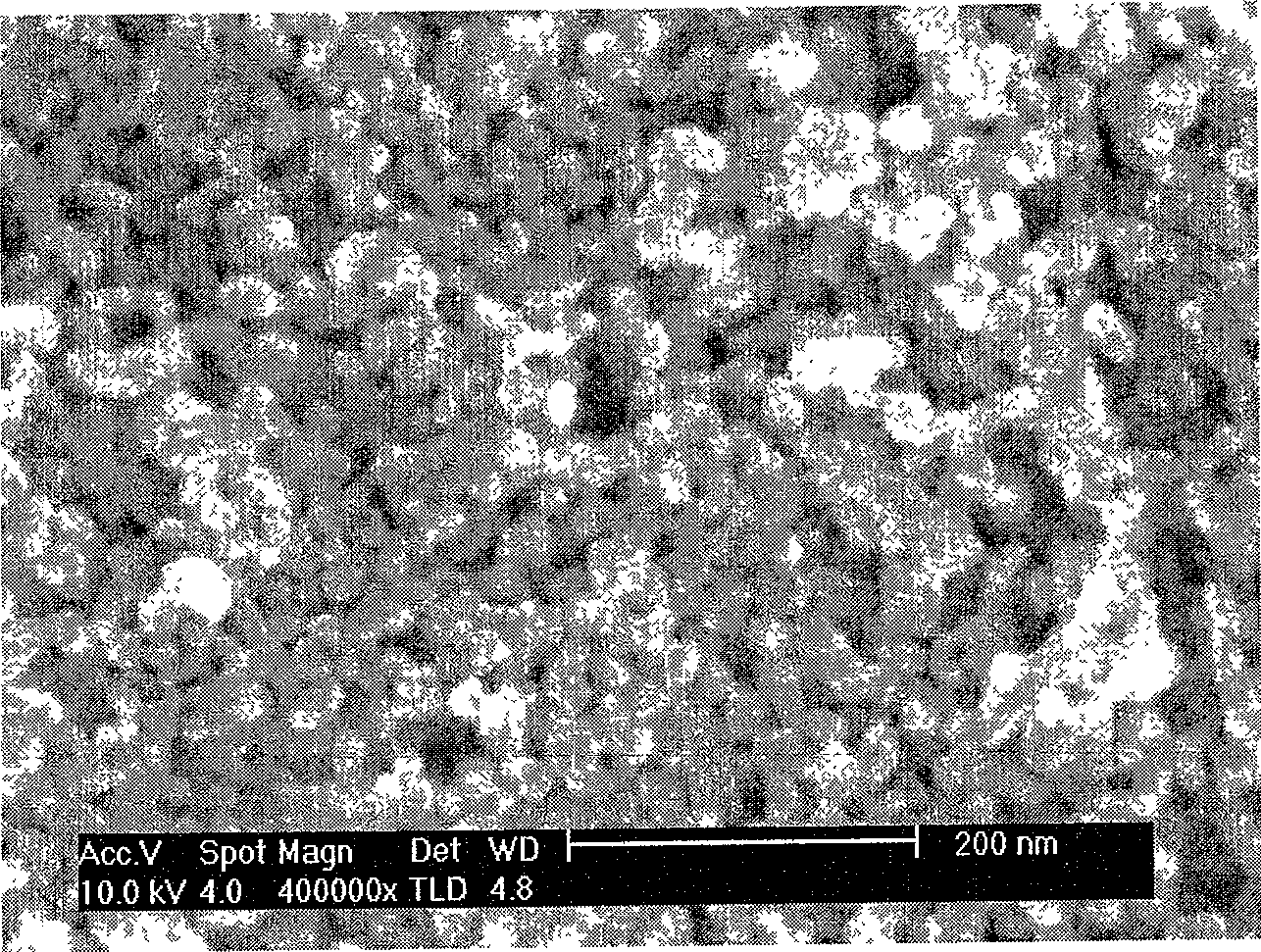

[0036] Present embodiment is made on the FTO glass substrate and is coated with 2 layers of nano-semiconductor material ZnO layers, obtains nano-semiconductor material ZnO porous film, and the aperture of irregular hole is 0.01-2 nanometer; Film thickness is at 1 micron, and film porosity is at 30% , the specific surface area can be 40 square meters per gram.

[0037] The concrete method that present embodiment makes nano-semiconductor material ZnO porous film is as follows:

[0038] 1) preparation solution concentration is the aqueous acetic acid solution of 0.2wt%;

[0039] 2) Mix 3g of ZnO nanopowder (with a particle size of 20 nanometers) with 15g of acetic acid aqueous solution, grind and mix it on a ball mill for 1 hour, then leave it at room temperature for 30 minutes to obtain a nanometer ZnO slurry;

[0040] 3) on the FTO glass substrate, apply the nano-ZnO slurry film prepared in step 2) by scraping, and apply it for 3 times to obtain a film layer with the same semi...

Embodiment 2

[0043] Present embodiment is made on the FTO glass substrate and is coated with 3 layers of nano-semiconductor material ZnO layers, obtains nano-semiconductor material ZnO porous film, and the aperture of irregular hole is 1 nanometer; Film thickness is at 4 microns, and film porosity is at 40%, ratio The surface area can be in the range of 60 m2 / g.

[0044] The concrete method that present embodiment makes nano-semiconductor material ZnO porous film is as follows:

[0045] 1) preparation solution concentration is the acetic acid aqueous solution of 1wt%;

[0046] 2) Mix 3g of ZnO nanopowder (with a particle size of 20 nanometers) with 8g of acetic acid aqueous solution, grind and mix it on a ball mill for 1 hour, then leave it at room temperature for 30 minutes to obtain a nanometer ZnO slurry;

[0047] 3) on the FTO glass substrate, apply the nano-ZnO slurry film prepared in step 2) by scraping, and apply it for 3 times to obtain a film layer with the same semiconductor. Af...

Embodiment 3

[0050] Present embodiment is made on the FTO glass substrate and is coated with 3 layers of nano-semiconductor material ZnO layers, obtains nano-semiconductor material ZnO porous film, and the aperture of irregular hole is 0.1-5 nanometer; Film thickness is at 12 microns, and film porosity is at 40% , the specific surface area can be 60 square meters per gram.

[0051] The concrete method that present embodiment makes nano-semiconductor material ZnO porous film is as follows:

[0052] 1) preparation solution concentration is the acetic acid aqueous solution of 3wt%;

[0053] 2) Mix 3g of ZnO nanopowder (with a particle size of 20 nanometers) with 3g of acetic acid aqueous solution, grind and mix on a ball mill for 1 hour, then leave at room temperature for 30 minutes to obtain a nanometer ZnO slurry;

[0054] 3) On the FTO glass substrate, apply the nano-ZnO slurry film prepared in step 2) by scraping, and apply it for 3 times to obtain a film layer with the same semiconducto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com