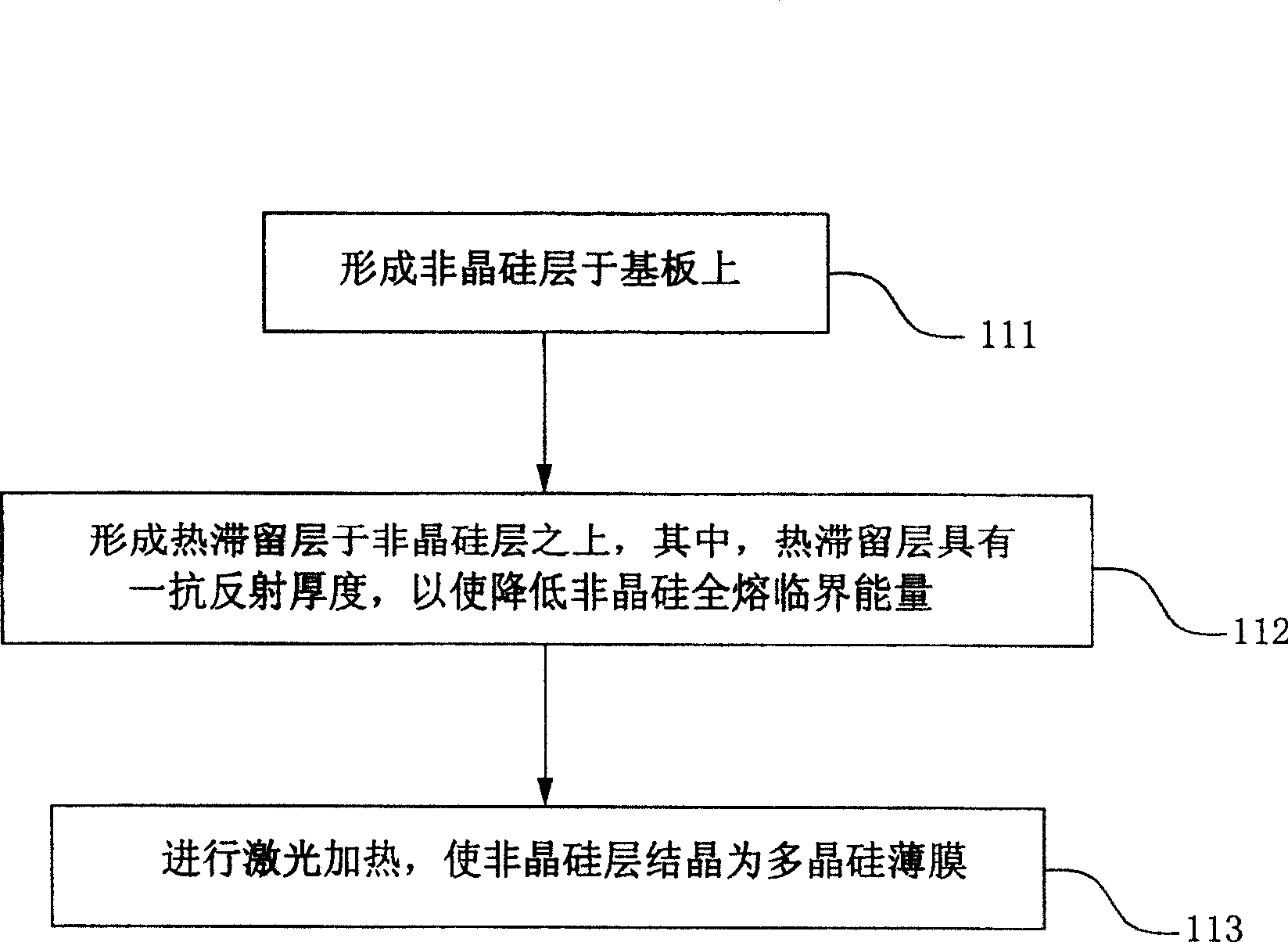

Auxiliary laser crystallization method for making polysilicon

An auxiliary laser, polysilicon technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of small laser operation energy process window, increased production cost, unstable energy output, etc., to achieve good laser crystal quality, Improved distribution uniformity and increased process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

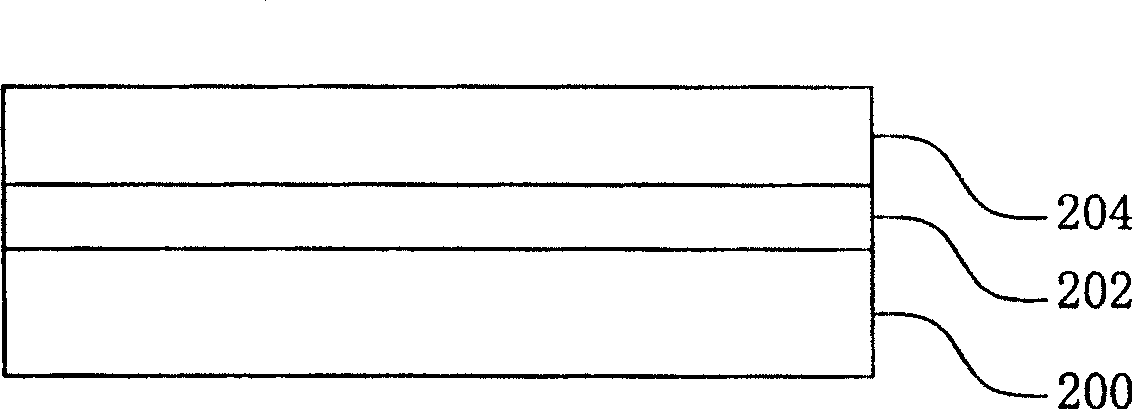

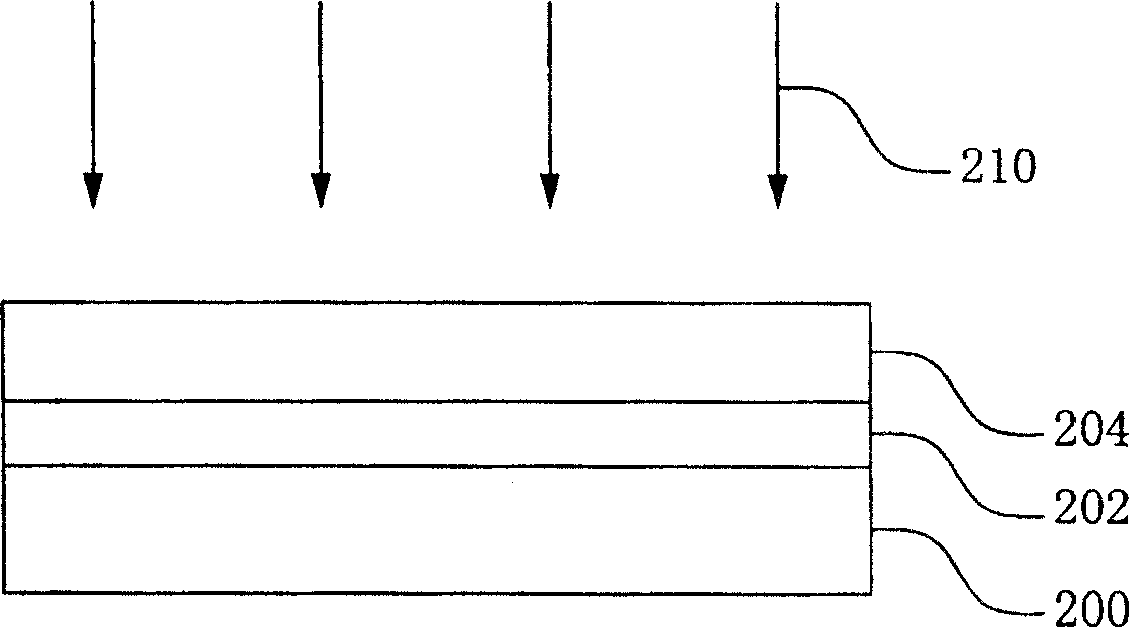

[0025] The present invention discloses a method for assisting laser crystallization of polysilicon. In the laser crystallization process of the amorphous silicon layer, in order to prolong the melting time of the amorphous silicon layer, a film material with semi-transparent properties can be selected as a heat retention layer to cover the amorphous silicon layer to be crystallized . In this way, when the laser light source is irradiated, in addition to part of the laser light source directly penetrating the amorphous silicon, there is also a part of the laser light source that can be absorbed by the heat retention layer, which has an additional heating effect on the amorphous silicon, thereby prolonging the cooling of the molten silicon. The time is in favor of the growth of large-sized crystal grains.

[0026] However, generally, the thermal stagnation layer with translucent properties also has partial light reflection properties at the same time, so the operating laser ene...

Embodiment 2

[0038] The present invention also discloses another method for assisted laser crystallization applied to the production of polysilicon, which uses two thermal retention layers that also have a thermal retention effect to cover the amorphous silicon. Control to achieve the anti-reflection effect on the laser light source. On the one hand, through the selection of the material of the thermal stagnation layer, the thermal stagnation layer has appropriate electrical properties for the fabrication of the thin film transistor element structure.

[0039] refer to Figures 4A-4B , Figures 4A-4B It is a schematic cross-sectional view of a method for assisting laser crystallization according to the second preferred embodiment of the present invention. First, refer to Figure 4A , to first form an amorphous silicon layer 402 on a substrate 400, wherein the amorphous silicon layer 402 is formed by, for example, plasma-assisted chemical vapor deposition or physical vapor deposition. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com