Electroplating method for negative pole case of mercury-free alkaline battery

A technology for alkaline batteries and negative poles of batteries, which is applied in the field of electroplating of negative shells of mercury-free alkaline batteries, can solve problems such as rough appearance, high inflation rate, and environmental pollution, and achieves easy popularization and application, prevention of gas expansion, and simple method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

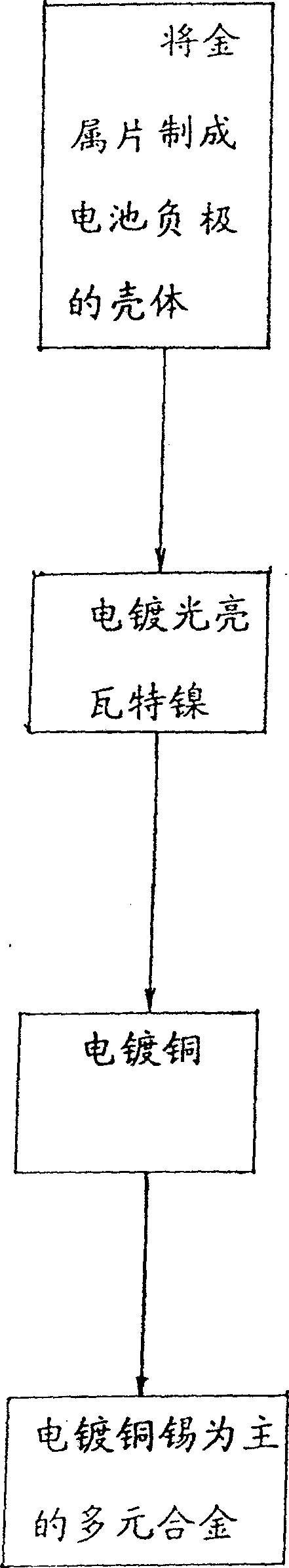

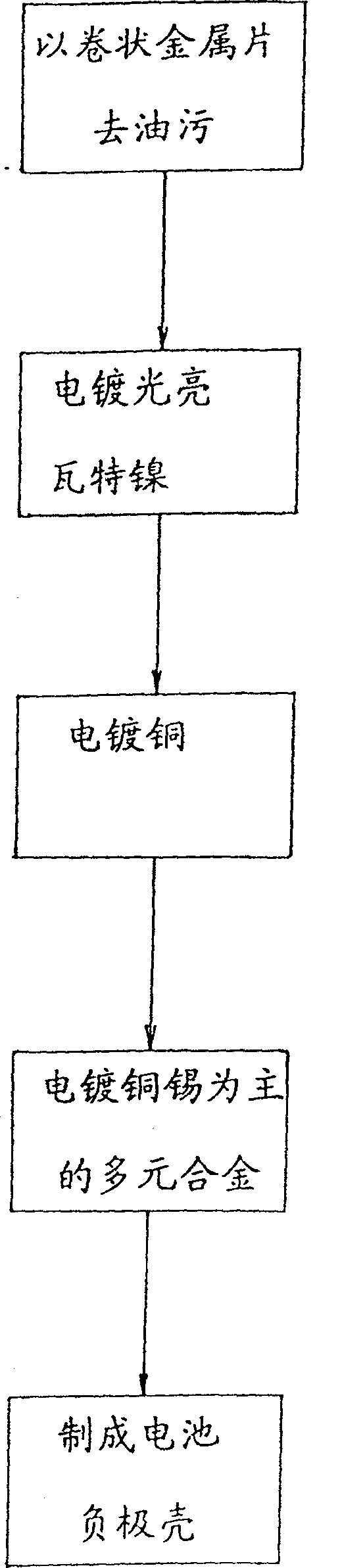

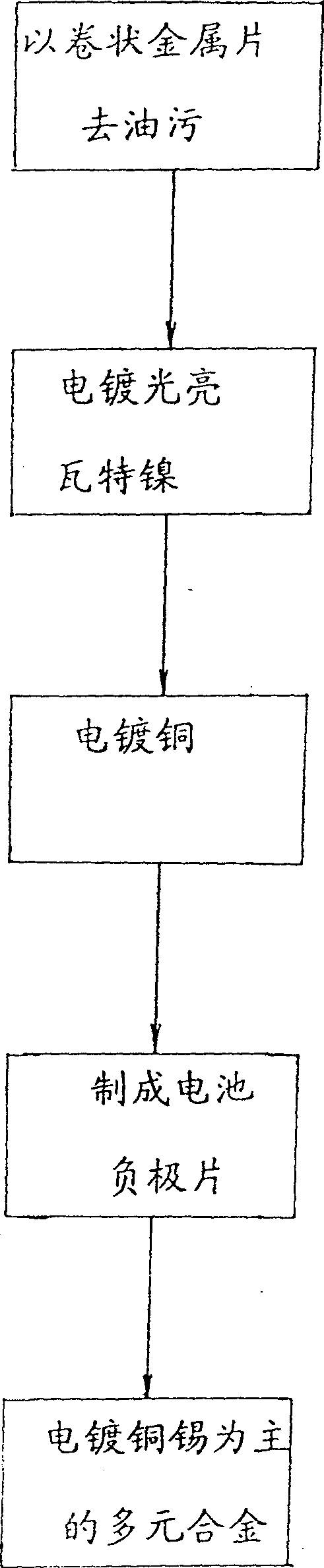

Method used

Image

Examples

specific Embodiment approach 2

[0067] Carry out according to specific embodiment one, just: the electroplating method of described a kind of mercury-free alkaline battery negative electrode case, in the multi-element alloy plating bath based on one liter of copper-tin alloy, contain:

[0068] 6 grams of copper ions provided by cuprous cyanide,

[0069] 20 g of free cyanogen provided by potassium cyanide,

[0070] 10 g of tin ions provided by potassium stannate,

[0071] Sodium hydroxide 0.71 g,

[0072] Provided by sulfates, oxides, organic salts, halogen compounds, amphoteric metal salts, nitrates, hydroxides and containing indium, zinc, cobalt, nickel, zirconium, molybdenum, palladium, lead, Trace metal ions of bismuth ions 500PPM,

[0073] 0.01 g of organic matter provided by the nonionic surfactant;

[0074] Follow the steps below:

[0075] ①. Select the metal sheet of stainless steel sheet to make the battery negative shell;

[0076] ②. Plating bright watt nickel on the battery negative shell;

...

specific Embodiment approach 3

[0082] Carry out according to specific embodiment one, just: the electroplating method of described a kind of mercury-free alkaline battery negative electrode case, in the multi-element alloy plating bath based on one liter of copper-tin alloy, contain:

[0083] 10 g of copper ions provided by copper oxide,

[0084] 30 g of free cyanide provided by sodium cyanide,

[0085] Tin ions provided by sodium stannate 15 g,

[0086] Potassium hydroxide 17 g,

[0087] Provided by sulfates, oxides, organic salts, halogen compounds, amphoteric metal salts, nitrates, hydroxides and containing indium, zinc, cobalt, nickel, zirconium, molybdenum, palladium, lead, Trace metal ions of bismuth ions 1500PPM,

[0088] 1.5 grams of organic matter provided by anions containing 6-20 carbon chains;

[0089] Follow the steps below:

[0090] ①. Select the metal sheet of the iron sheet to make the battery negative shell;

[0091] ②. Plating bright watt nickel on the battery negative shell;

[009...

specific Embodiment approach 4

[0097] Carry out according to specific embodiment one, just: the electroplating method of described a kind of mercury-free alkaline battery negative electrode case, in the multi-element alloy plating bath based on one liter of copper-tin alloy, contain:

[0098] Copper ions provided by cuprous cyanide 14 g,

[0099] 40 g of free cyanogen provided by potassium cyanide,

[0100] Tin ions provided by potassium stannate 20 g,

[0101] Sodium hydroxide 12.15 g,

[0102] Provided by sulfates, oxides, organic salts, halogen compounds, amphoteric metal salts, nitrates, hydroxides and containing indium, zinc, cobalt, nickel, zirconium, molybdenum, palladium, lead, Trace metal ions of bismuth ions 2500PPM,

[0103] 1.5 grams of organic matter provided by nonionic surfactant;

[0104] Follow the steps below:

[0105] ①. Select the metal sheet of stainless steel sheet to make the battery negative shell;

[0106] ②. Plating bright watt nickel on the battery negative shell;

[0107] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com