A crash selection method for thrown lead acid accumulator and special tower gravity selector

A waste lead-acid battery, gravity separation technology, applied in battery recycling, recycling technology, waste collector recycling and other directions, can solve the problems of high operating costs, expensive equipment, high sulfuric acid concentration, to solve corrosion problems, equipment stability Reliable and effective in eliminating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

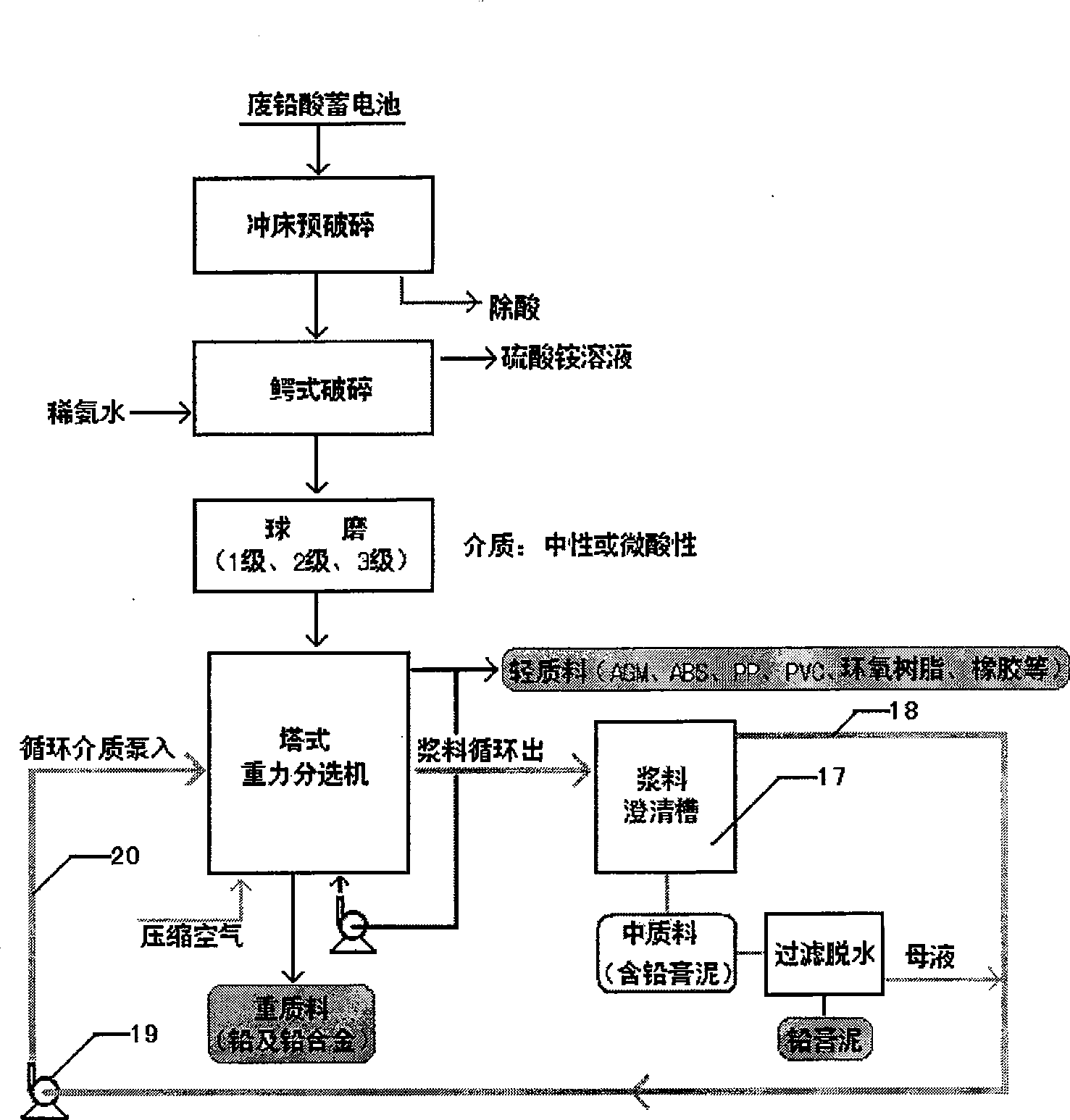

Method used

Image

Examples

Embodiment 1

[0032] The crushing equipment selected impact bed (provided by Zhejiang University of Technology), crocodile crusher (Shanghai Yuanhua Machinery Factory, PE-150×250) and horizontal ball mill (provided by Zhejiang University of Technology), with a processing capacity of 1 ton of waste batteries / h .

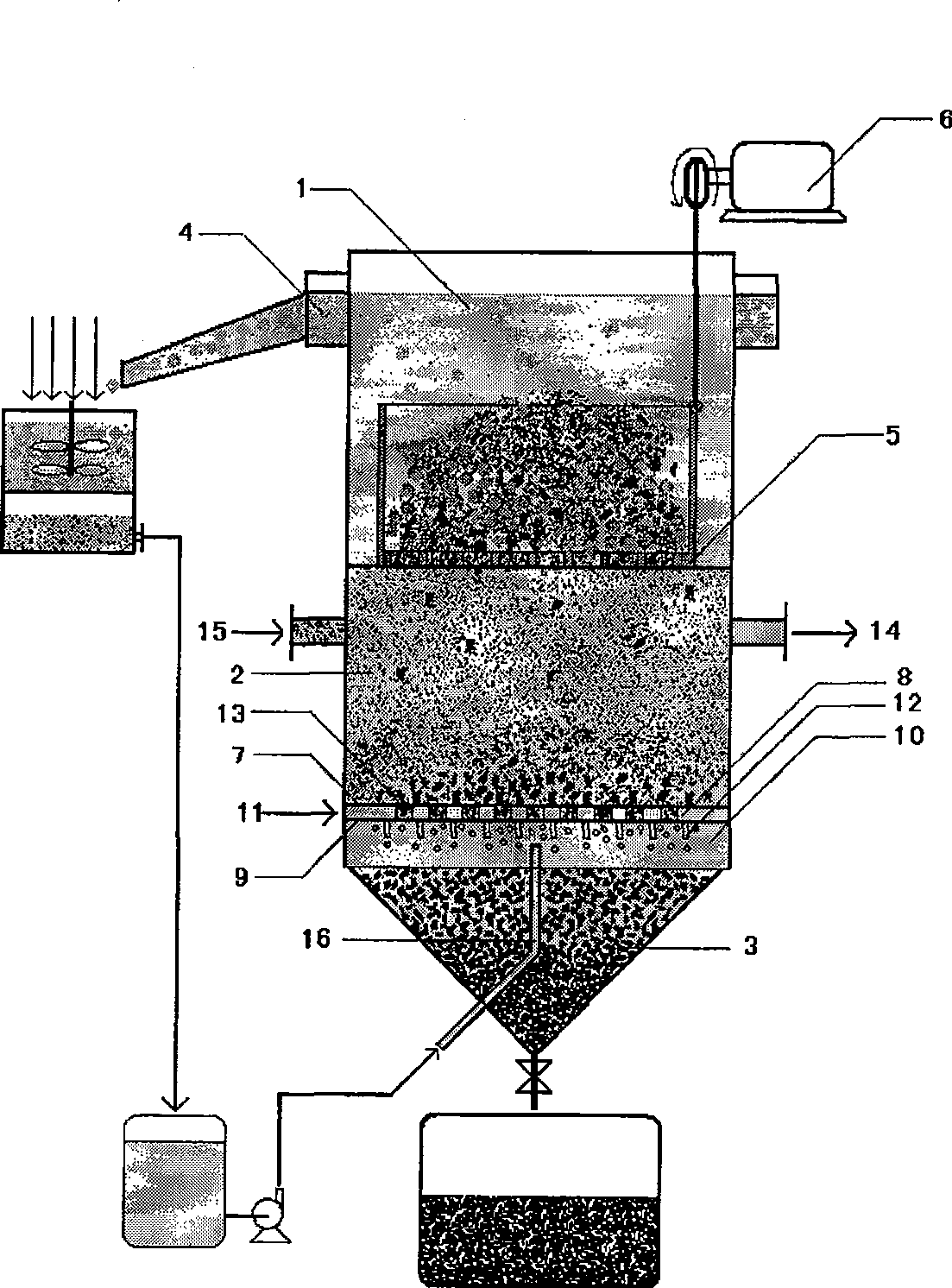

[0033] The sorting equipment adopts the tower gravity sorter, the structure see figure 1, the top of the feed chamber 1 is provided with a light material outlet 4, and the bottom of the feed chamber is connected to the slurry circulation chamber 2. A porous vibrating frame 5 is provided, and the porous vibrating frame is connected with the curved roller machine 6; the bottom of the slurry circulation chamber is connected to the A fluid flow uniform distribution plate 7 is arranged at the junction of the heavy material collection tank 3, and the fluid flow uniform distribution plate is composed of an air chamber 8, a screening plate 9 and a gas transition chamber 10, and the air cha...

Embodiment 2

[0038] Used device is the same as embodiment 1, and the flow rate of the pump that conveys liquid at the bottom of the tower is 75m 3 / h, the flow rate of the pump conveying the bypass circulating liquid in the middle of the tower is 35m 3 / h, the bubbling pressure of compressed air is 2.5 atmospheres.

[0039] The actual operation has been carried out in the crushing and sorting equipment mentioned above, and the process is as follows.

[0040] Take 1000kg of waste batteries and put them into a punching machine for primary crushing. The primary crushed materials are then put into a crocodile crusher. While mechanically crushing, inject 15% ammonia water to adjust the pH of the medium to 5-6. After the medium is purified and treated to remove metal ions, it is treated with lime water and converted into dilute ammonia water for recycling.

[0041] After the crushed materials are finely ground step by step by a ball mill, the particle size of the lead-containing paste mud mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com