Polyureas microcapsule and its preparation method

A technology of microcapsules and polyurea, which is applied in the field of preparation of polyurea microcapsules, can solve the problems of insufficient safety, unfriendly environment, high toxicity and volatility, and achieve high safety, low toxicity and volatility, Quick and thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 0.45g of Tween 80 (Tween80) was completely dissolved in 75ml of distilled water, and it was divided into two portions of 62.5ml and 12.5ml for later use.

[0023] A mixture of 4,4-diphenylmethane diisocyanate and 2,4-diphenylmethane diisocyanate, wherein the weight of 2,4-diphenylmethane diisocyanate is 40±5%,

[0024] Add 25ml of organic solvent cyclohexane and 2g of diphenylmethane diisocyanate to 62.5ml of the above-mentioned Tween 80 aqueous solution, and transfer all the solution into a three-necked flask, stir, emulsify into emulsion A, and use the remaining 12.5ml Add Tween 80 aqueous solution and 0.5g diethylenetriamine (DETA) to form solution B, add B to emulsion A, and initiate interfacial polymerization reaction on the water-oil interface.

[0025] The reaction temperature was 25° C., and the reaction was carried out for 4 hours.

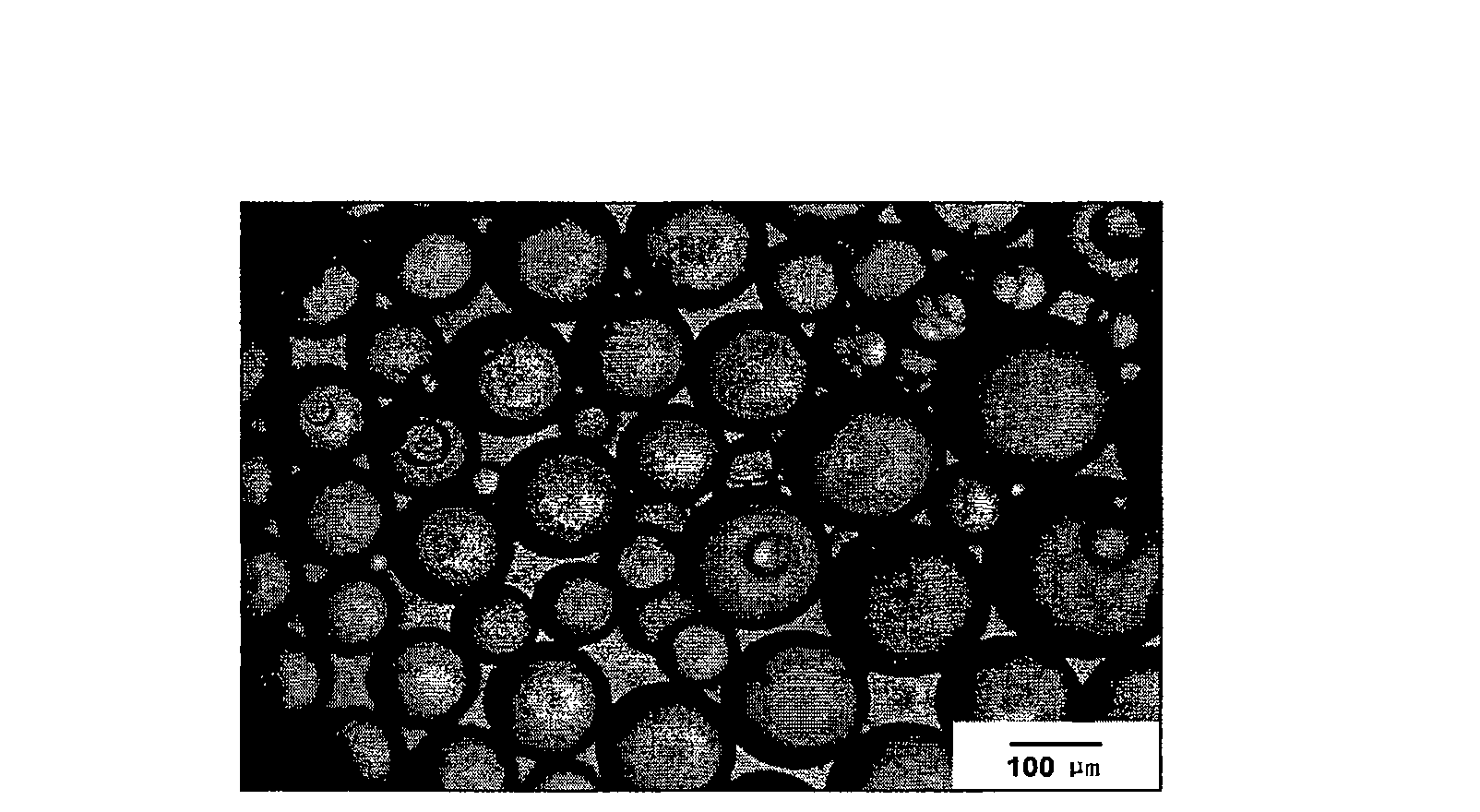

[0026] After the reaction is completed, take a fresh microcapsule suspension sample to observe and take pictures under an optica...

Embodiment 2

[0029] 0.45g of polyvinyl alcohol (PVA) was dissolved in 75ml of distilled water, and it was divided into two parts of 62.5ml and 12.5ml for later use.

[0030] Add 25ml of the prepared organic solvent butyl acetate and 0.5g of diphenylmethane diisocyanate to 62.5ml of the above-mentioned PVA aqueous solution, and transfer all the solution into a three-necked flask, stir, and emulsify into a water-in-oil emulsion A , the remaining 12.5ml of PVA distilled water plus 0.2g of diethylenetriamine (DETA) was made into a solution, slowly added to the emulsion system, and interfacial polymerization was initiated on the water-oil interface.

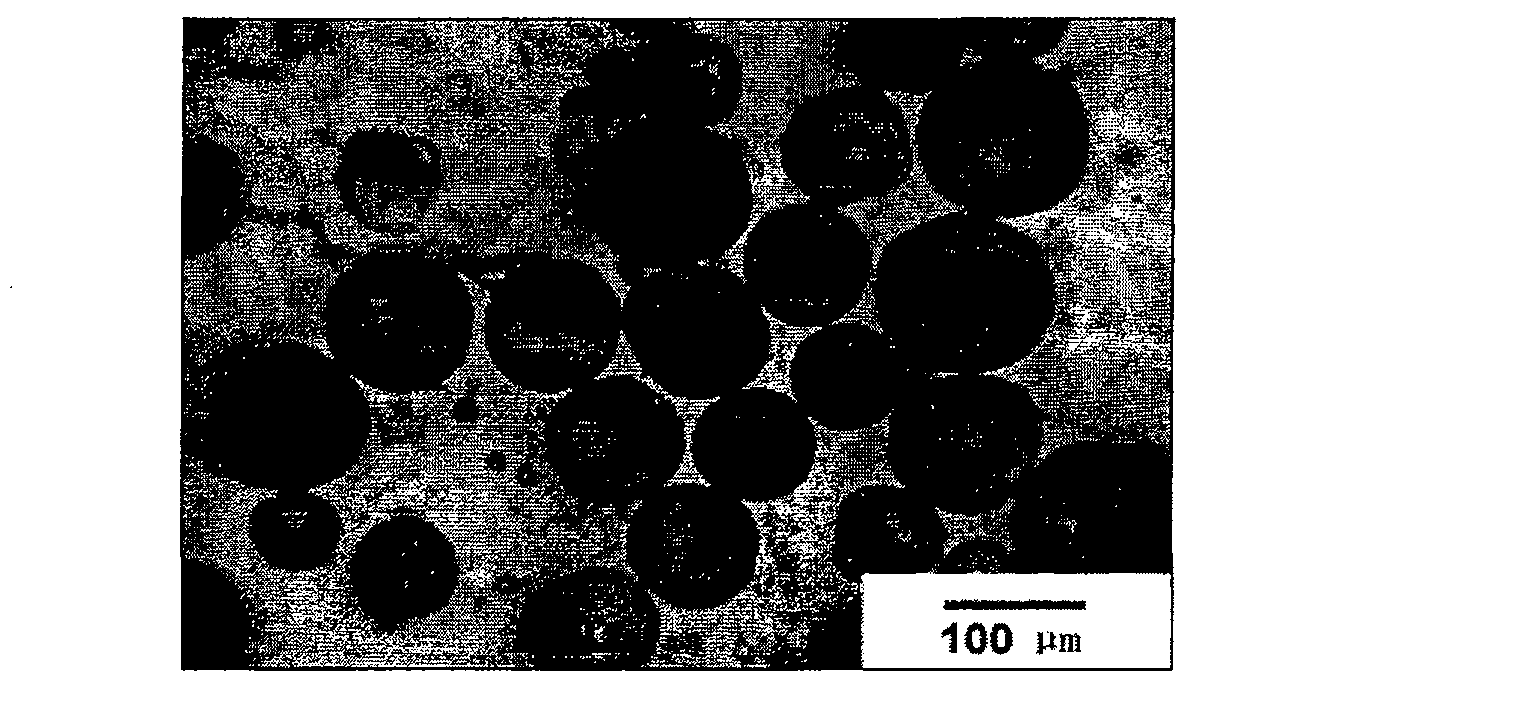

[0031] The reaction temperature was controlled at 30° C., and the reaction was carried out for 3.5 hours. The processing after completion of the reaction is the same as in Example 1. figure 2 Be the optical micrograph of the polyurea microcapsule suspension of embodiment 2.

[0032] The average particle size of the microcapsules prepared in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com