Colorless transparent polyimide composite film and its production method

一种聚酰亚胺、复合薄膜的技术,应用在该复合薄膜的制备领域,能够解决不能适用、薄膜不良表面平滑度、薄膜不良可塑性等问题,达到优良耐热性和机械性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

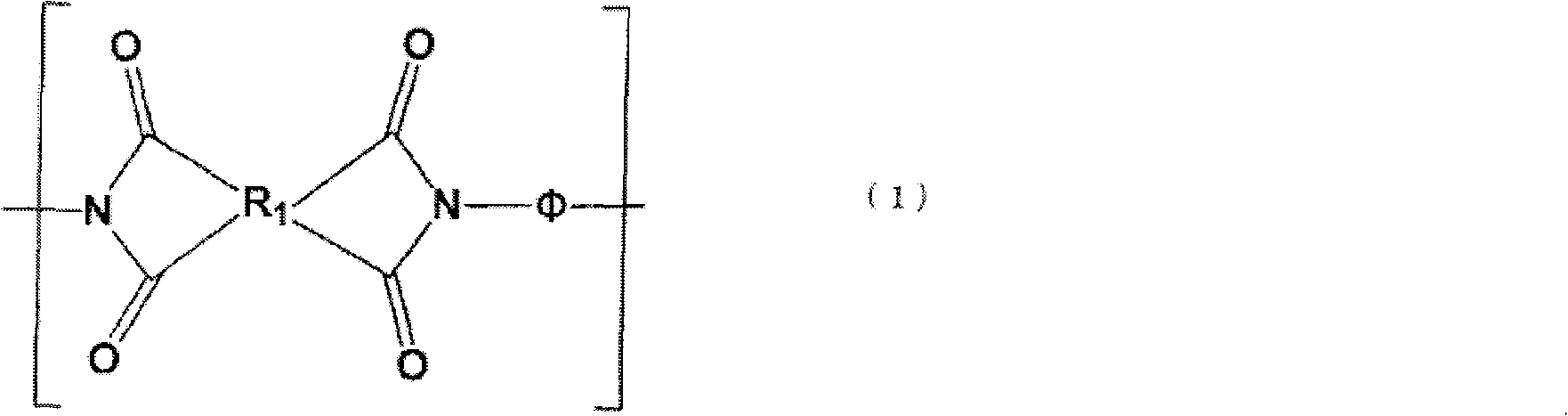

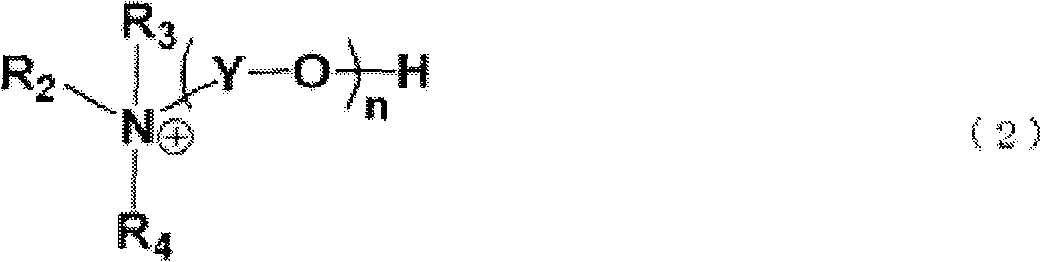

[0038] The colorless transparent polyimide composite film of the present invention contains the polyimide (A) that has the repeating unit represented by formula (1) and by treating with the organic onium ion represented by formula (2) or (3) The obtained organically treated layered silicate (B). The preparation method of the colorless and transparent polyimide composite film of the present invention comprises: by the layered silicate (B) that contains polyimide (A), organic treatment and have the organic solvent (C) of specific SP value The three-component liquid mixture of is extruded or applied on a carrier to form a film-form mixture; the organic solvent (C) is subsequently removed from the film-form mixture.

[0039] The polyimide (A) having a repeating unit represented by formula (1) used in the present invention is obtained by a reaction between an aliphatic tetracarboxylic acid or a derivative thereof and a diamine.

[0040] Examples of the aliphatic tetracarboxylic ac...

Embodiment

[0088] The present invention will be described in detail below by means of examples, and it should not be understood that the present invention is limited to these examples.

[0089] The physical properties of polyimides, two-component liquid mixtures (each containing an organically treated layered silicate and an organic solvent) and polyimide composite films obtained in Examples and Comparative Examples were measured by the following methods .

[0090] Evaluation method of polyimide

[0091]

[0092] Polyimide (0.1 g) was dissolved in N-methyl-2-pyrrolidone (20 ml), and at 30° C., the inherent viscosity of polyimide was measured by a Canon-Fenske viscometer . The inherent viscosity (μ) was calculated by using the following formula.

[0093] μ=[ln(t s / t o )] / C

[0094] t o : Solvent flow time

[0095] t s : dilute polymer solution flow time

[0096] C: 0.5 g / dl

[0097]

[0098]

[0099] The turbidity of a two-component liquid mixture containing an organical...

preparation Embodiment 1

[0114]

[0115] Oxydianiline (20.12 g, 0.1 mol) and an organic solvent, namely, γ-butyrolactone (51.65 g) with an SP value of 12.6 and N, N-dimethylacetamide (12.92 g) with an SP value of 10.8 ) into a 500-milliliter five-neck flask equipped with a thermometer, a stirrer, a nitrogen introduction tube and a condenser with a fractionator, followed by dissolving oxydianiline in an organic solvent. The solution obtained above was cooled to 5°C by means of an ice-water bath. While keeping the solution at the same temperature as above, 1,2,4,5-cyclohexanetetracarboxylic dianhydride (22.62 g, 0.1 mol) and triethylamine (0.50 g , 0.005 mol) were added to the above solution together. After the addition was complete, the resulting mixture was heated to 180°C and refluxed for three hours, the distillate was removed if necessary, then heated to 200°C to complete the reaction. After air cooling until the internal temperature was 100°C, N,N-dimethylacetamide (107.6 g) serving as a dilue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com