Polypropylene block copolymer and its preparation process and use

A polypropylene block and copolymer technology, which is applied to the polypropylene block copolymer and its preparation and application fields, can solve the problems of harsh conditions, difficult reaction control, and difficulty in product purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

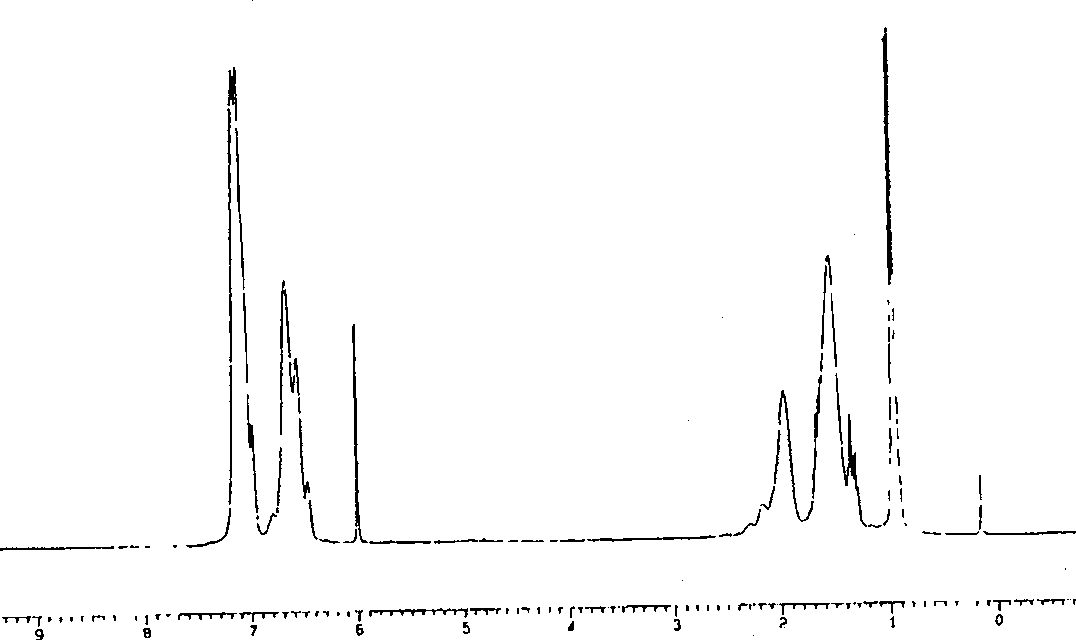

Image

Examples

Embodiment 1

[0072] Example 1. Preparation of polypropylene block polystyrene copolymer

[0073] 1. Preparation of polypropylene terminated with styrene monomer units

[0074] The polymerization was carried out in a stainless steel reactor equipped with mechanical stirring. First, it was pumped with nitrogen gas for three times, and then with propylene gas for two times. Then, 100 ml of toluene, 2 ml of styrene, 2.5 mmol of methylaluminoxane (MAO), 2.5 μmol of dimethylsilyl bis(2-methyl) were added in sequence. -4-naphthyl-indenyl) zirconium dichloride, firstly feed 0.1MPa hydrogen, then feed propylene gas at a certain pressure, and finally keep the pressure of propylene at 0.7MPa, and the polymerization reaction is continued at 35°C for 30 minutes. Then, the material was discharged, precipitated with hydrochloric acid and ethanol, and filtered to obtain a white solid, which was then washed twice with tetrahydrofuran, and vacuum-dried at 60° C. to obtain a polypropylene with a styrene mon...

Embodiment 2

[0079] Example 2. Preparation of polypropylene block poly-p-methyl polystyrene copolymer

[0080] The polymerization was carried out in a stainless steel reactor equipped with mechanical stirring. First, it was pumped with nitrogen gas three times, and then with propylene gas for two times. Then, 100 ml of toluene, 0.1 ml of styrene, 0.01 mmol of methylaluminoxane (MAO), and 0.3 μmol of dimethylsilyl bis(2-methyl) were added in sequence. (base-4-naphthyl-indenyl) zirconium dichloride, first pass 0.1 MPa of hydrogen, and then pass into a certain pressure of propylene gas, and finally keep the pressure of propylene at 0.7 MPa, and the polymerization reaction is continued at 35 ° C for 30 min. Then, the material was discharged, precipitated with hydrochloric acid and ethanol, and filtered to obtain a white solid, which was then washed twice with tetrahydrofuran, and vacuum-dried at 60° C. to obtain a polypropylene containing styrene structural units at the end.

[0081] In a 250...

Embodiment 3

[0084] Example 3. Preparation of polypropylene block polyvinyl acetate copolymer

[0085]The polymerization was carried out in a stainless steel reactor equipped with mechanical stirring. First, evacuated three times with nitrogen gas, and then evacuated twice with propylene gas, and sequentially added 100 ml of hexane, 10 ml of styrene, 50 mmol of methylaluminoxane (MAO), and 50 μmol of dimethylsilyl bis(2-methyl) -4-naphthyl-indenyl) zirconium dichloride, firstly, 0.1MPa hydrogen was introduced, and then a certain pressure of propylene gas was introduced. Finally, the pressure of propylene was kept at 0.7MPa, and the polymerization reaction was continued at 35° C. for 10 minutes. Then, the material was discharged, precipitated with hydrochloric acid and ethanol, and filtered to obtain a white solid, which was then washed twice with tetrahydrofuran, and vacuum-dried at 60° C. to obtain a polypropylene containing styrene structural units at the end.

[0086] In a 250ml three-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com