Method for producing isopropyl myristate

A technology of isopropyl myristate and myristate is applied in the production field of isopropyl myristate, and can solve the problems of non-degradation, environmental pollution, and difficulty in controlling the production cost of pesticides and fungicides. problem, to achieve the effect of easy degradation and ensure purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

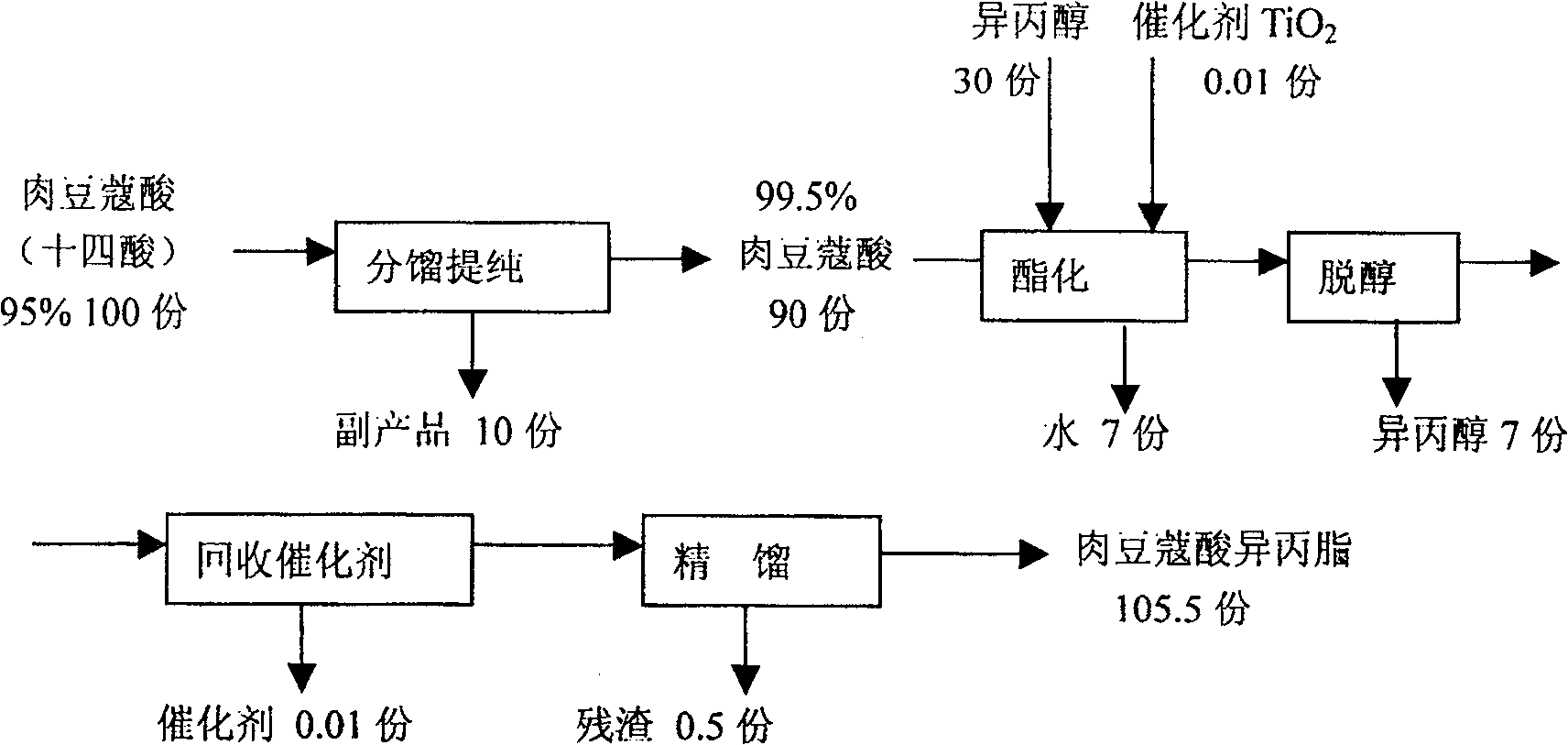

[0012] With 100 parts of 95% myristic acid (myristic acid) as raw material, adopt such as figure 1 The steps shown make 105.5 parts of isopropyl myristate of the present invention, wherein, 10 parts of by-products of fractional distillation and purification gained are a mixture of 3 parts of lauric acid, 5 parts of palmitic acid and 2 parts of myristic acid.

Embodiment approach 2

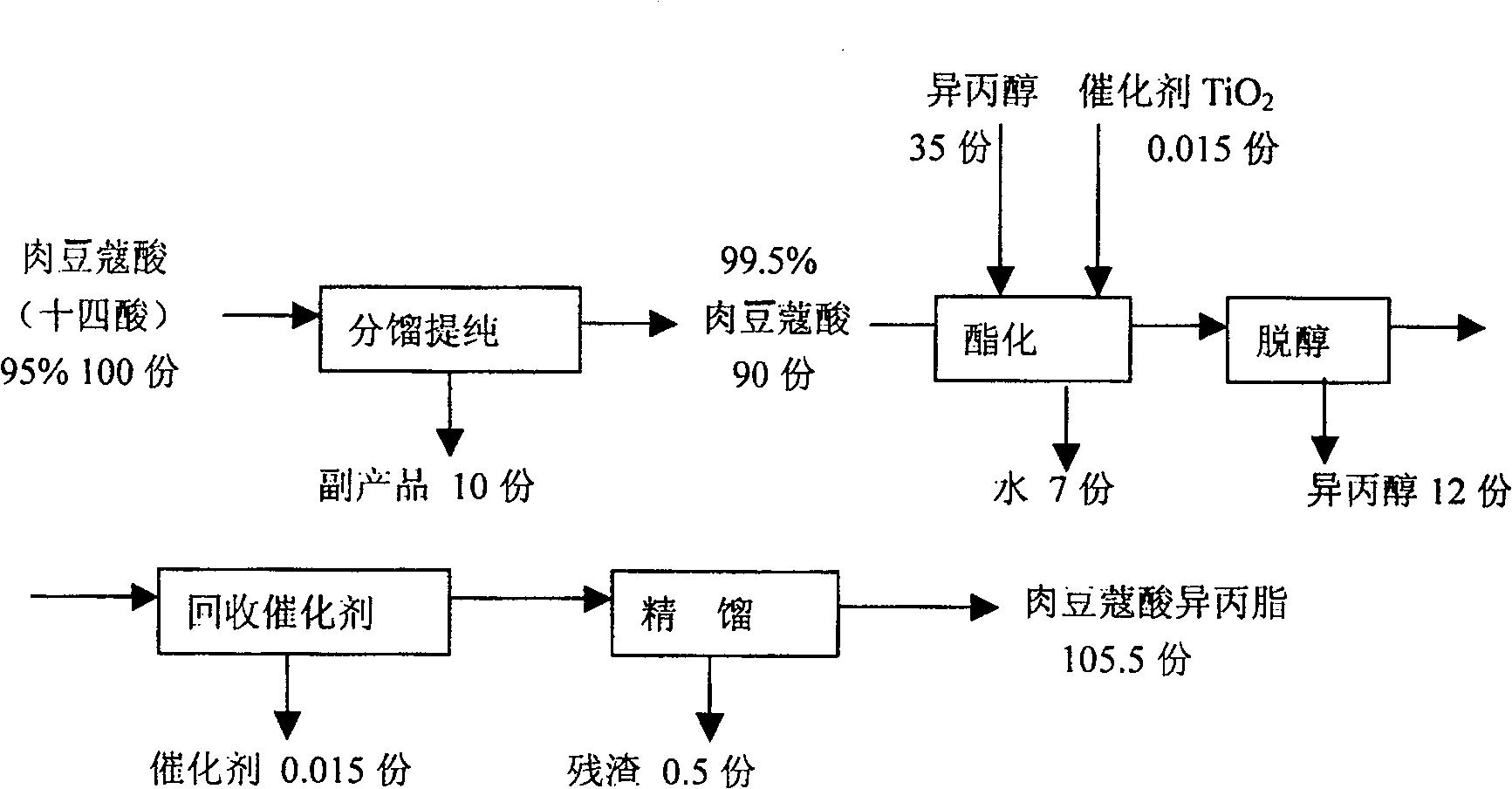

[0014] With 100 parts of 95% myristic acid (myristic acid) as raw material, adopt such as figure 2 Step shown, make 105.5 parts of isopropyl myristate of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com