Process for preparing epoxy-compound by catalytic oxidation of alpha-olefin by metal porphyrin

A technology of epoxy compounds and metalloporphyrins, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc. To achieve the effect of mild reaction conditions, simple solvent composition, easy and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

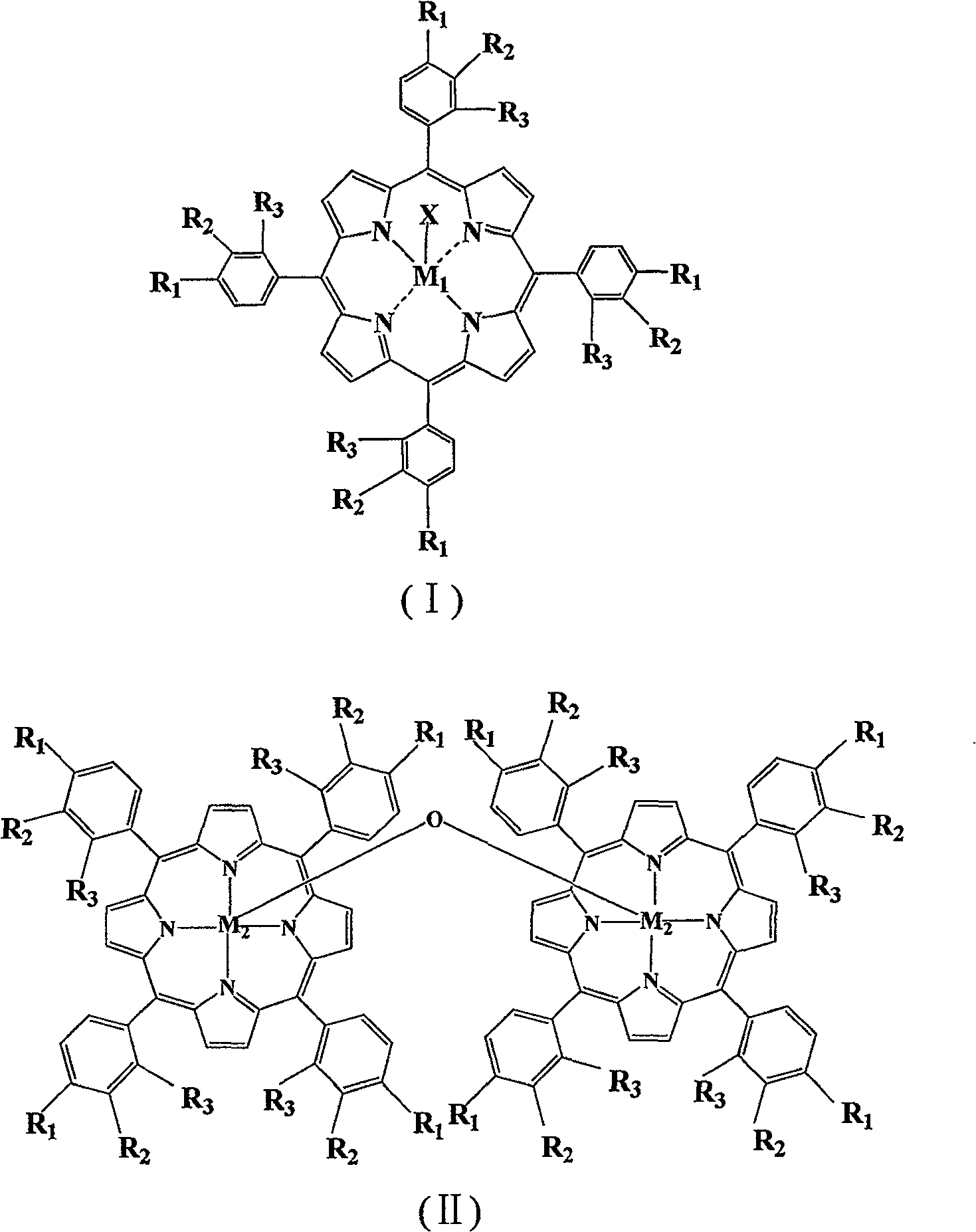

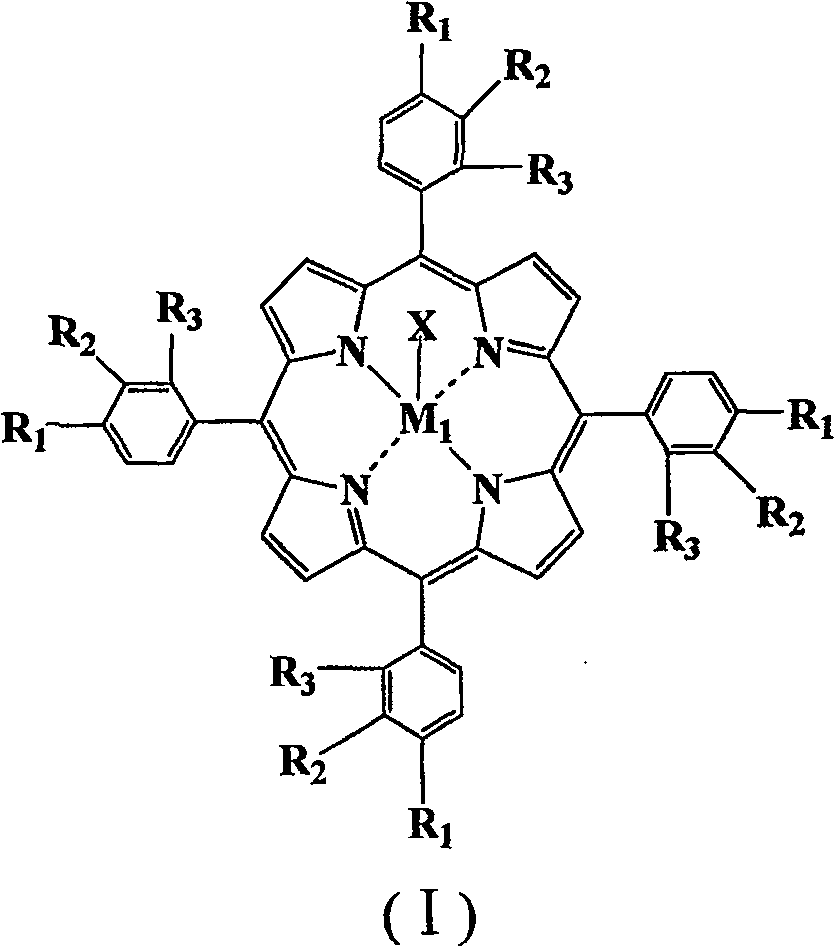

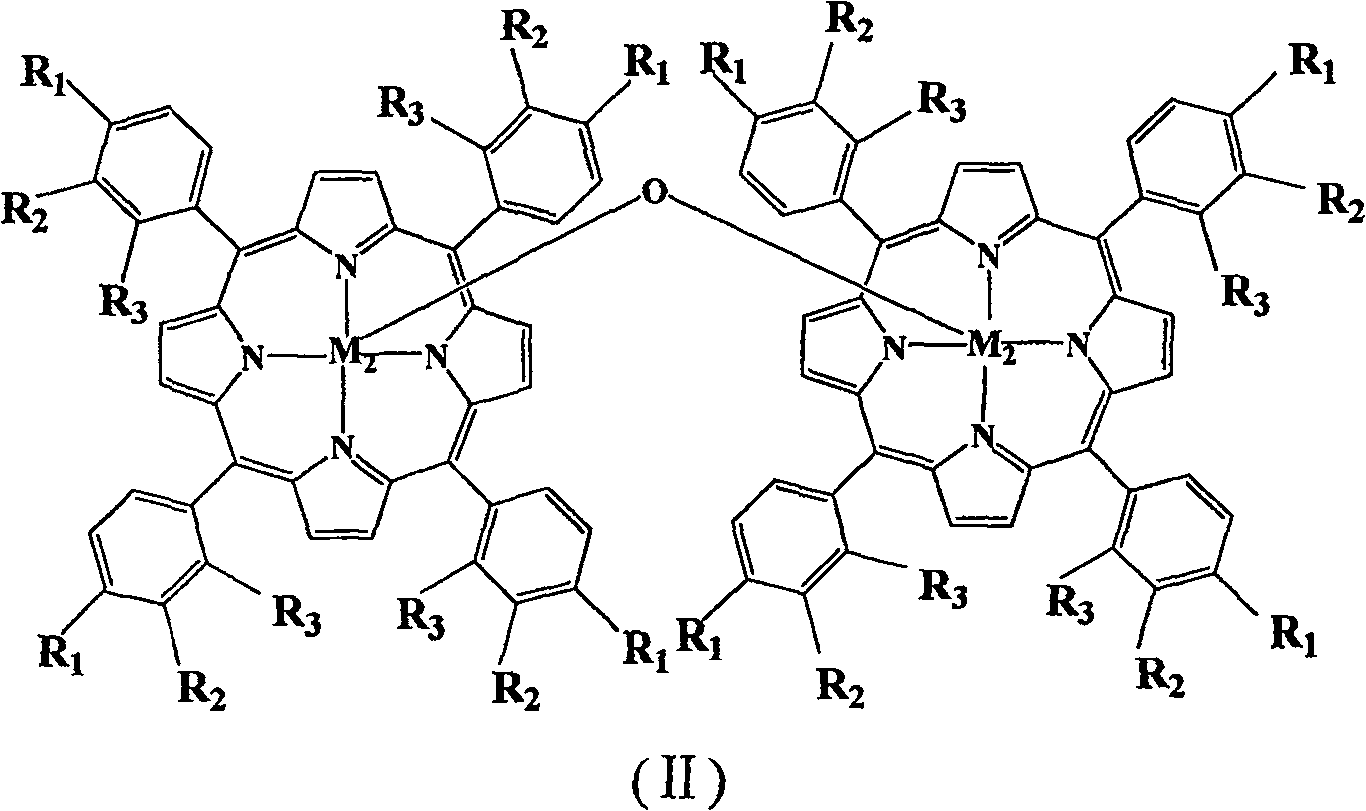

Method used

Image

Examples

Embodiment 1

[0019] In a 100mL three-necked flask, add 50mL of dichloromethane, 3mL of 1-hexene, 2mg of mononuclear metalloporphyrins with general formula (I) structure (wherein R 1 =R 2 = H, R 3 =OCH 3 , X=Cl, M 1 =Fe), the reaction temperature was controlled to be 10° C., air was fed under normal pressure, and the reaction was carried out for 8 hours to obtain hexane oxide. According to gas chromatography analysis, the conversion rate of 1-hexene was 84%, the yield of hexane oxide was 80%, and the selectivity was 95%.

Embodiment 2

[0021] In a 100mL three-necked flask, add 50mL of dichloromethane, 3mL of 1-octene, 2mg of mononuclear metalloporphyrins with general formula (I) structure (wherein R 1 =CH 3 , R 2 =R 3 = H, X = Cl, M 1 =Mn), the reaction temperature was controlled to be 35° C., oxygen gas was fed under normal pressure, and the reaction was carried out for 2.5 hours to obtain octane oxide. According to gas chromatography analysis, the conversion rate of 1-octene was 94%, the yield of epoxyoctane was 91.5%, and the selectivity was 97%.

Embodiment 3

[0023] In a 100mL three-necked flask, add 50mL of dichloromethane, 2mL of 1-nonene, 5mg of μ-oxobinuclear metalloporphyrins (where R 1 =R 2 =R 3 = H, M 2 =Co), the reaction temperature was controlled to be 38° C., and oxygen was fed under normal pressure, and the reaction was carried out for 6 hours to obtain nonane oxide. According to gas chromatography analysis, the conversion rate of 1-nonene was 90%, the yield of epoxy nonane was 86%, and the selectivity was 95.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com