Ionic liquid type hydrate inhibitor

A hydrate inhibitor, ionic liquid technology, applied in drilling composition, gas fuel, petroleum industry, etc., can solve the problem of immature development of kinetic inhibitor, poor solubility of kinetic inhibitor, inhibitor Problems such as unsatisfactory molecular structure, to achieve the effect of long inhibition time, reduced generation rate, and reduced contact opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] When the aqueous solution does not contain ionic liquid, the THF test is carried out, and the results are listed in Table 2.

Embodiment 2-4

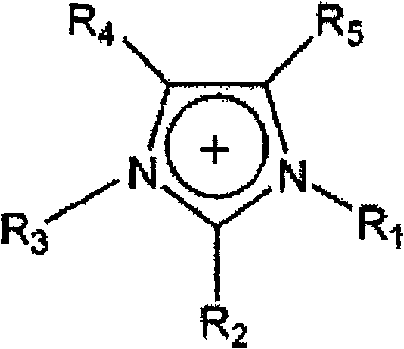

[0048] Preparation of ionic liquid:

[0049] Synthesis of quaternary ammonium halide salts by tertiary amines and alkyl halides, such as 1-butyl-3-methylimidazolium chloride salt ([C 4 mim][Cl]) synthesis:

[0050] The reaction requires an organic solvent and excess haloalkane. After heating to reflux for several hours, use a rotary evaporator to remove the remaining haloalkane from the organic solvent after the reaction is complete. The response is as follows:

[0051] mim+EtCl=[C 4 mim][Cl]

[0052] Preparation concentrations were 0.005, 0.01 and 0.05wt% [C 4 mim] [Cl] ionic liquid aqueous solution, carry out THF test, the results are shown in Table 2.

Embodiment 5-7

[0054] 1-Ethyl-3-methylimidazolium bromide ([C 4 mim] [Br]) is similar to that in Example 2-4, only need to replace EtCl with EtBr to obtain ([C 4 mim][Br]). Preparation concentration is respectively 0.005,0.01 and 0.05wt% ([C 4 mim][Br]) ionic liquid aqueous solution, carry out THF test, the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com