Titanium oxide nano wire film on metallic titanium surface and manufacture method thereof

A technology of titanium oxide and metal titanium, which is applied in the coating process of metal materials, etc., to achieve the effects of increased specific surface area, abundant production raw materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Place the pre-washed 1×1cm 2 The metal titanium sheet was etched with 5wt% oxalic acid solution at 100° C. for two hours, ultrasonically cleaned with deionized water, and dried to obtain a clean surface titanium metal sheet.

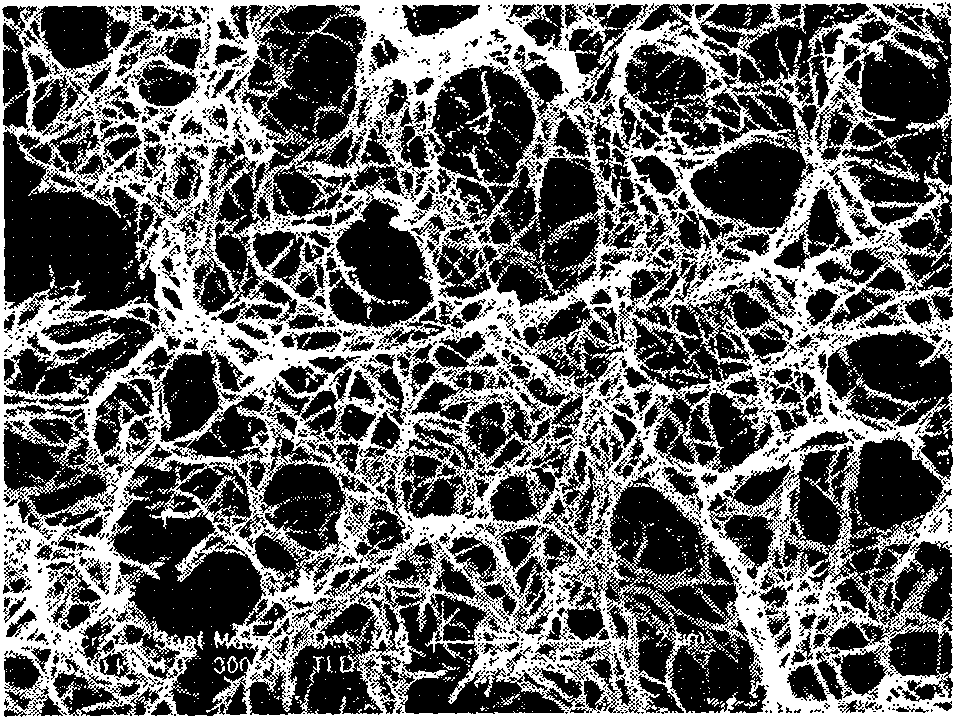

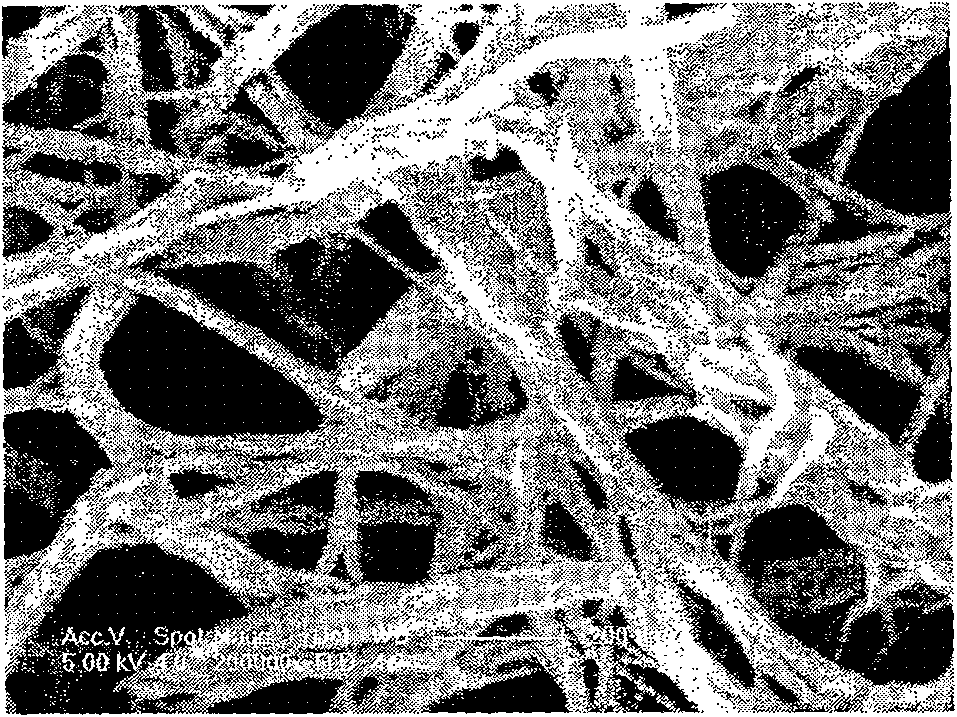

[0027] 2) The titanium sheet was immersed in an oxidation solution of 1ml NaOH (10M) and 1ml hydrogen peroxide (30%), placed in a closed reaction kettle and reacted in an oven at 80°C for 24 hours. After the reaction, the titanate nanowire network film on the titanium base is obtained, and the nanowire network structure formed on the surface is as follows: figure 1 and figure 2 As shown, it can be seen that nanowires with a diameter of about 40 nm are intertwined and intertwined to form pores of different sizes.

[0028] 3) Wash the titanium sheet of the titanate nanowire film formed above with deionized water, soak it in 0.1M hydrochloric acid for 0.5 hours, then rinse it with deionized water until neutral, perform the same operation three ...

Embodiment 2

[0032] 1) Place the pre-washed 2×4cm 2 The titanium metal sheet was etched in a mixture of hydrofluoric acid: nitric acid: deionized water with a volume ratio of 1:3:6 for 1 minute, ultrasonically cleaned with deionized water, and dried to obtain a titanium metal sheet with a clean surface.

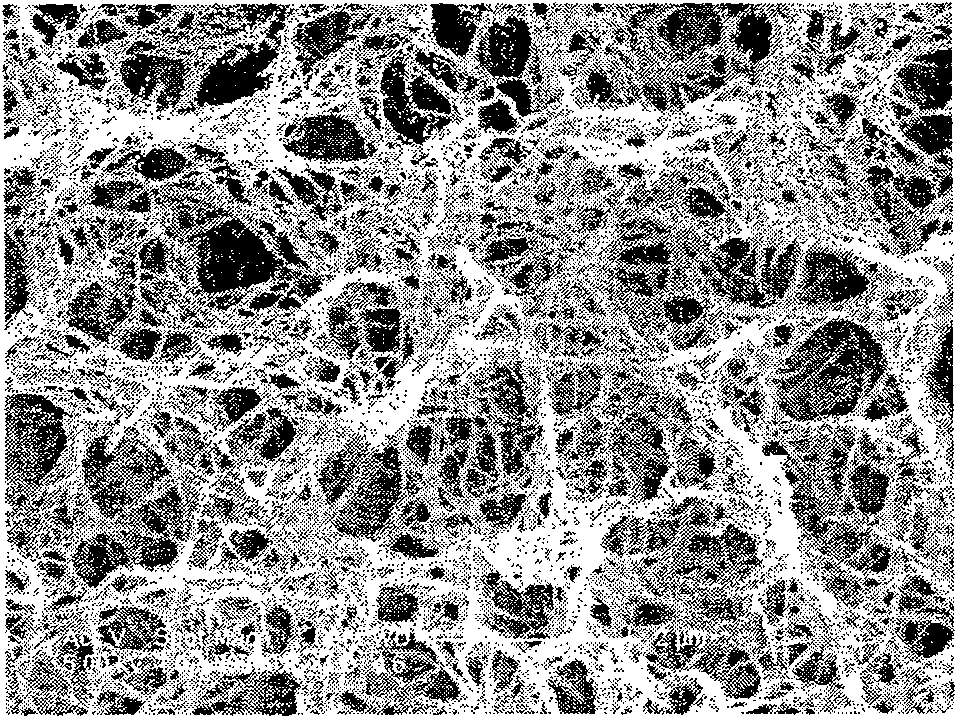

[0033] 2) The titanium sheet was immersed in an oxidation solution of 1.5ml NaOH (10M) and 15ml hydrogen peroxide (30%), placed in a closed reaction kettle and reacted in an oven at 80°C for 6 hours. After the reaction, the titanate nanowire network film on the titanium base is obtained, and the nanowire network structure formed on the surface is as follows: Figure 4 As shown, nanowires with a diameter of about 30-50 nm are intertwined and intertwined to form pores of a certain size.

[0034]3) Wash the titanium sheet of the titanate nanowire film formed above with deionized water, soak it in 0.05M hydrochloric acid for 1 hour, then rinse it with deionized water until it is neutral, per...

Embodiment 3

[0038] 1) Place the pre-washed 2×2cm 2 The metal titanium sheet was etched with 5wt% oxalic acid solution at 100°C for two hours, ultrasonically cleaned with deionized water, and dried to obtain a clean surface titanium sheet

[0039] 2) The titanium sheet was immersed in an oxidation solution of 2ml NaOH (10M) and 10ml hydrogen peroxide (30%), placed in a closed reaction kettle and reacted in an oven at 80°C for 12 hours. After the reaction, the titanate nanowire network film on the titanium base is obtained, and the nanowire network structure formed on the surface is as follows: Figure 6 shown.

[0040] 3) Wash the titanium sheet of the titanate nanowire film formed above with deionized water, soak it in 0.1M hydrochloric acid for 2 hours, then rinse it with deionized water until neutral, and dry it in an oven at 80°C. A titanate nanowire film on the surface of metal titanium is obtained.

[0041] 4) Calcining the metal titanium sheet with the titanate nanowire film form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com