Automobile and electronic waste recovery process and its system

A technology of electronic waste and recycling system, which is applied in the field of environmental protection and resource recovery, can solve the problems of high energy consumption, processing cost and thermal pollution that cannot be ignored, and the inability to recycle and process other electromechanical products and waste cars at the same time, so as to reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

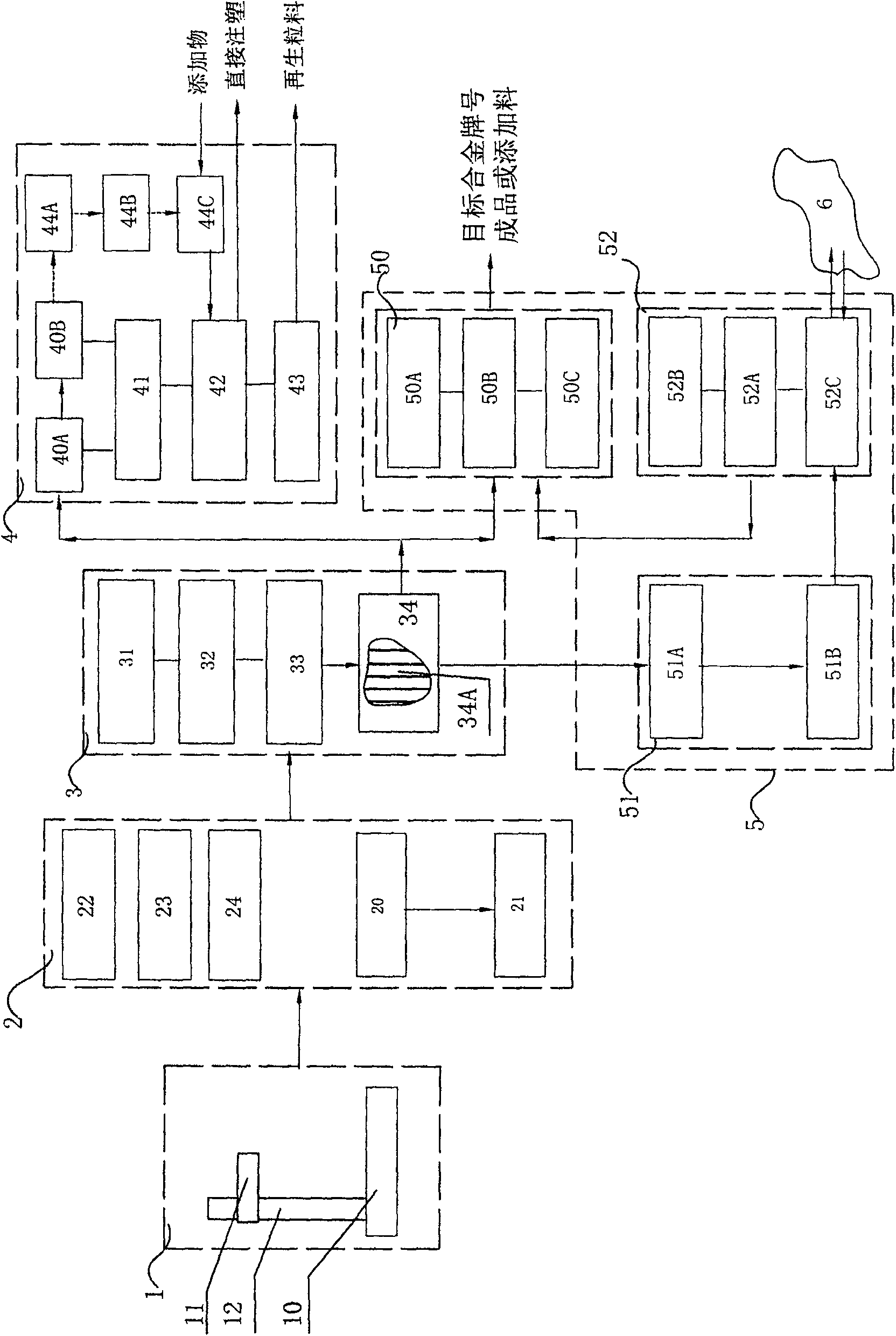

[0032] Recycling process and system embodiment:

[0033] Such as figure 1 , which is a schematic diagram of an embodiment of the recycling system for automobiles and electronic wastes of the present invention. The recovery system includes dismantling equipment 1, crushing equipment 2, sorting equipment 3, plastic recycling equipment 4 and metal parts deep processing equipment 5,

[0034] The dismantling equipment 1 includes a workbench 10 with a clamp 11 and a lift 12, and the clamp 11 includes an electric clamp and a manual clamp. The above-mentioned dismantling equipment 1 disassembles the non-melting welding and interconnected parts on the waste articles to obtain disassembled parts including metal parts, non-metal parts and circuit board parts; the metal parts in the dismantled parts are manually and / or Mechanical separation equipment is further separated into various metal parts; and then the non-metallic parts in the split parts are further separated into glass, rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com