Silk broadcloth scouring agent

A scouring agent and scouring technology are applied in the field of scouring agents for textile finishing and silk scouring processing to achieve the effects of enhancing the washing effect, improving the scouring effect and shortening the scouring time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The prescription of the scouring agent that is used for real silk scouring process is composed as follows by weight part:

[0020] Sodium N,N'-difatty acyl ethylenediamine dipropionate: 10%

[0021] Sodium Alkyl Polyoxyethylene Ether Carboxylate: 12%

[0022] Maleic / acrylic acid copolymer: 8%

[0023] Glycerol Glucose: 3%

[0024] Yuanming powder: 2%

[0025] the rest is water;

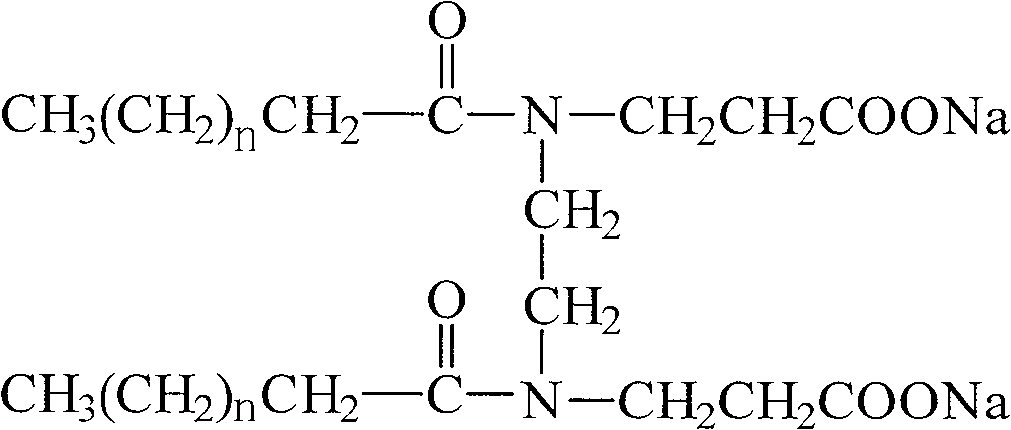

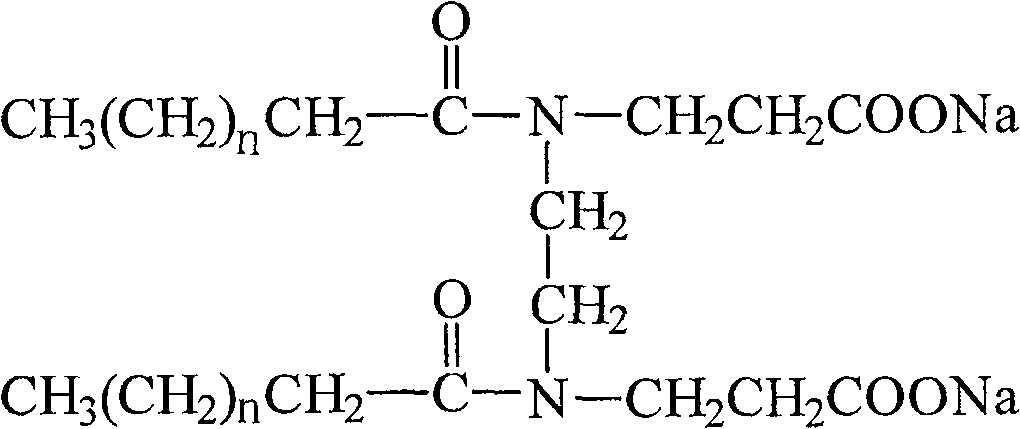

[0026] Used N, N '-difatty acyl ethylenediamine dipropionate sodium structure is as follows:

[0027]

[0028] The sodium alkyl polyoxyethylene ether carboxylate structure used is as follows:

[0029] C 12 h 25 O(CH 2 CH 2 O) 3 CH 2 COONa

[0030] The maleic acid / acrylic acid copolymer used is a conventional industrial product, and its molecular weight can be between 1000 and 2000.

Embodiment 2

[0032] Its formula for the scouring agent of real silk scouring process is composed as follows by weight:

[0033] Sodium N,N'-difatty acyl ethylenediamine dipropionate: 12%

[0034] Sodium alkyl polyoxyethylene ether carboxylate: 6%

[0035] Maleic / acrylic acid copolymer: 8%

[0036] Lauryl sucrose ester: 3%

[0037] Salt: 3%

[0038] the rest is water;

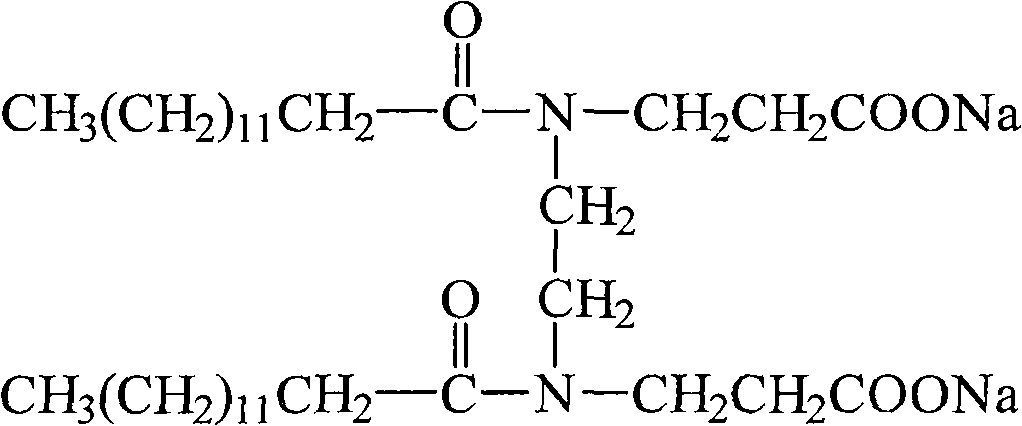

[0039] Used N, N '-difatty acyl ethylenediamine dipropionate sodium structure is as follows:

[0040]

[0041] The sodium alkyl polyoxyethylene ether carboxylate structure used is as follows:

[0042] C 14 h 29 O(CH 2 CH 2 O) 5 CH 2 COONa

[0043] The maleic acid / acrylic acid copolymer used is a conventional industrial product, and its molecular weight can be between 1000 and 2000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com