Method for making gallium nitride based laser tube core using face-down bonding technique

A gallium nitride-based, laser technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems that affect the working performance and life of the die, and the heat dissipation effect is not good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

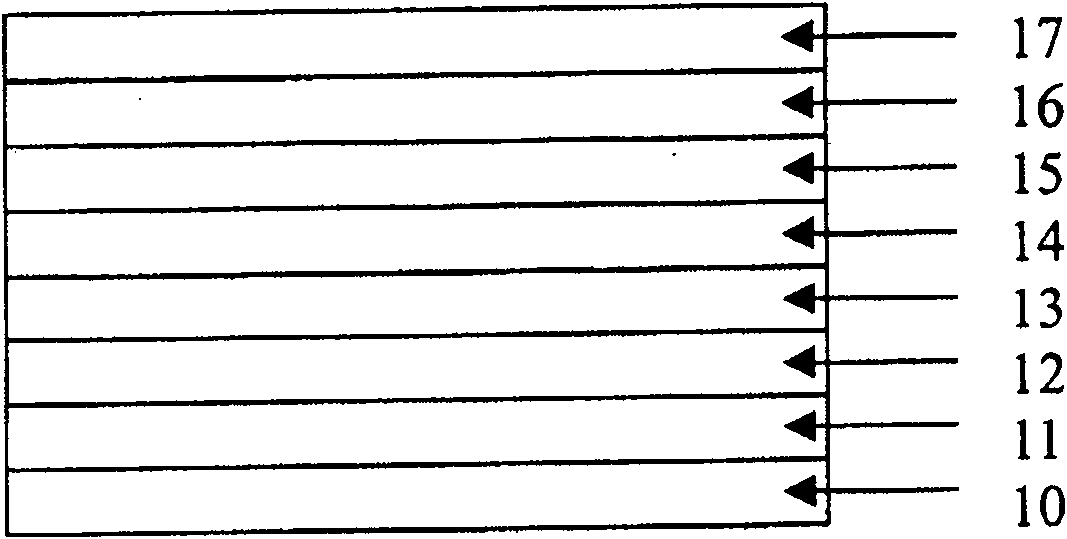

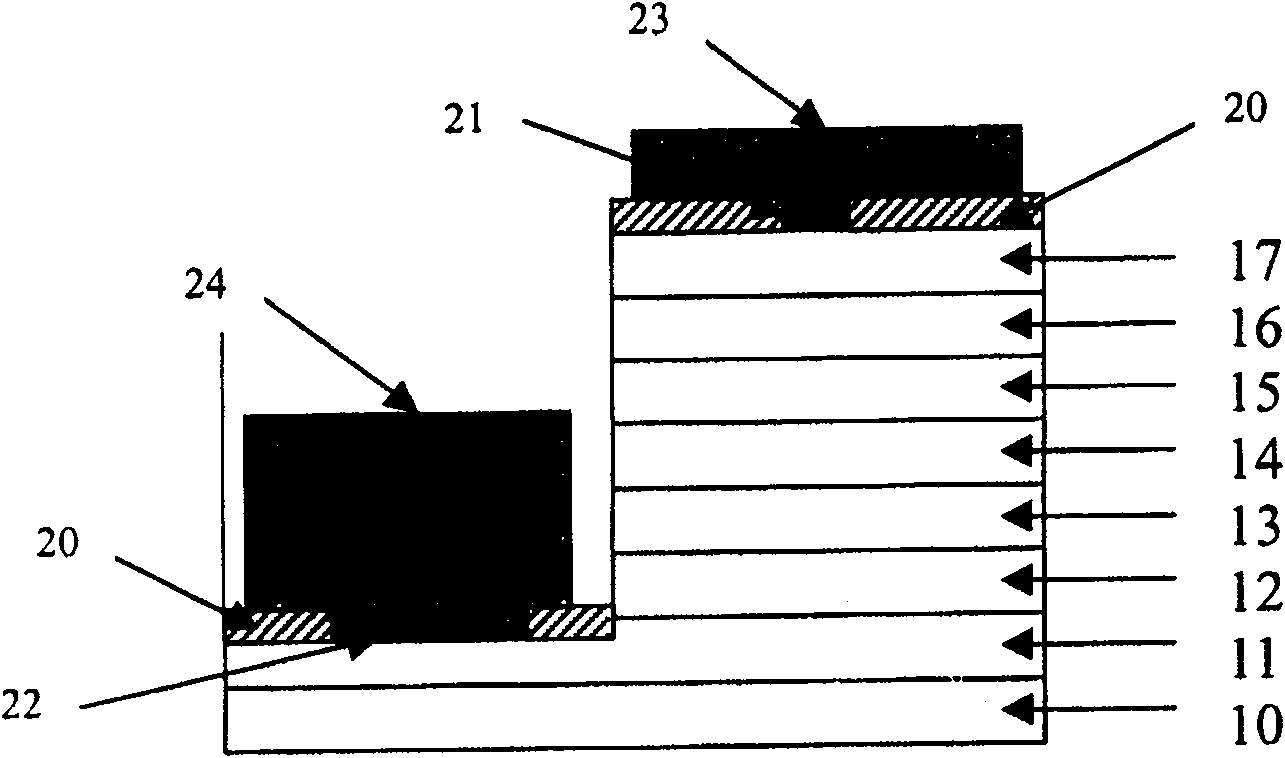

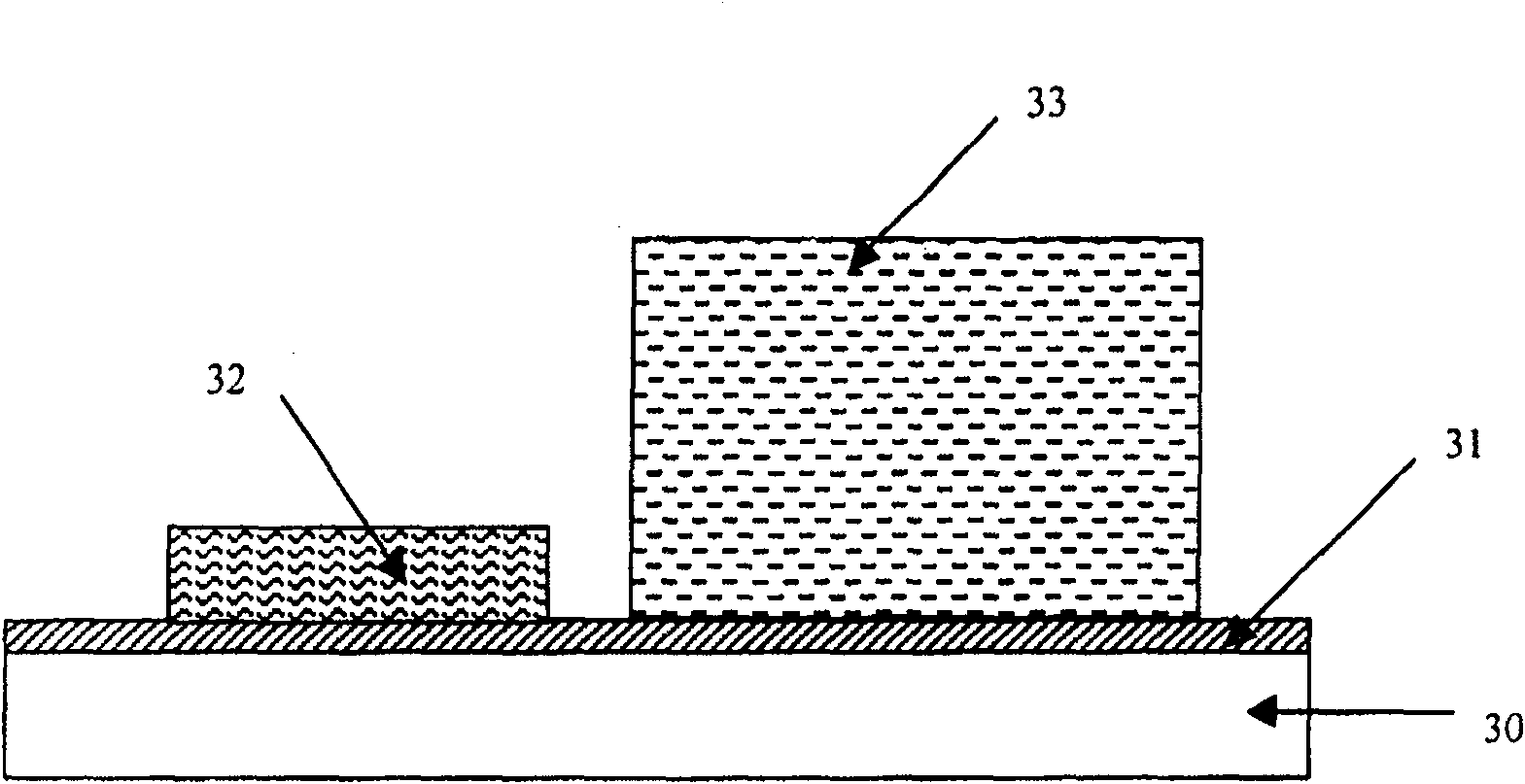

[0025] See first figure 1 As shown, this is a cross-sectional view of a gallium nitride-based laser die structure. The manufacturing process is to epitaxially grow a GaNN-type electrode contact layer 11 and an N-type AlGaN optical confinement layer 12 on a sapphire substrate 10 by using the MOCVD method. N-type GaN waveguide layer 13 , light emitting active region 14 , P-type GaN waveguide layer 16 , P-type AlGaN optical confinement layer 16 and P-type GaN electrode contact layer 17 . see again figure 2 As shown, the width of the die of the laser is designed to be 250 microns, the structure of the gallium nitride-based laser die and the size of the corresponding die division channel are designed, and the designed N-type electrode contact area and division are made using ion beam etching technology. The channel area is etched to the N-type GaN electrode contact layer, and then a layer of silicon dioxide insulating film 20 with a thickness of 0.2 microns is deposited on the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com