Acrylate polymer capillary vessel electric chromatogram monolithic column modified by macrocyclic polyamines and preparation thereof

A technology of capillary electrochromatography and macrocyclic polyamine, which is applied in the fields of analytical chemistry and polymer chemistry, and can solve the problems of complex substance separation without specific selectivity and limited application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

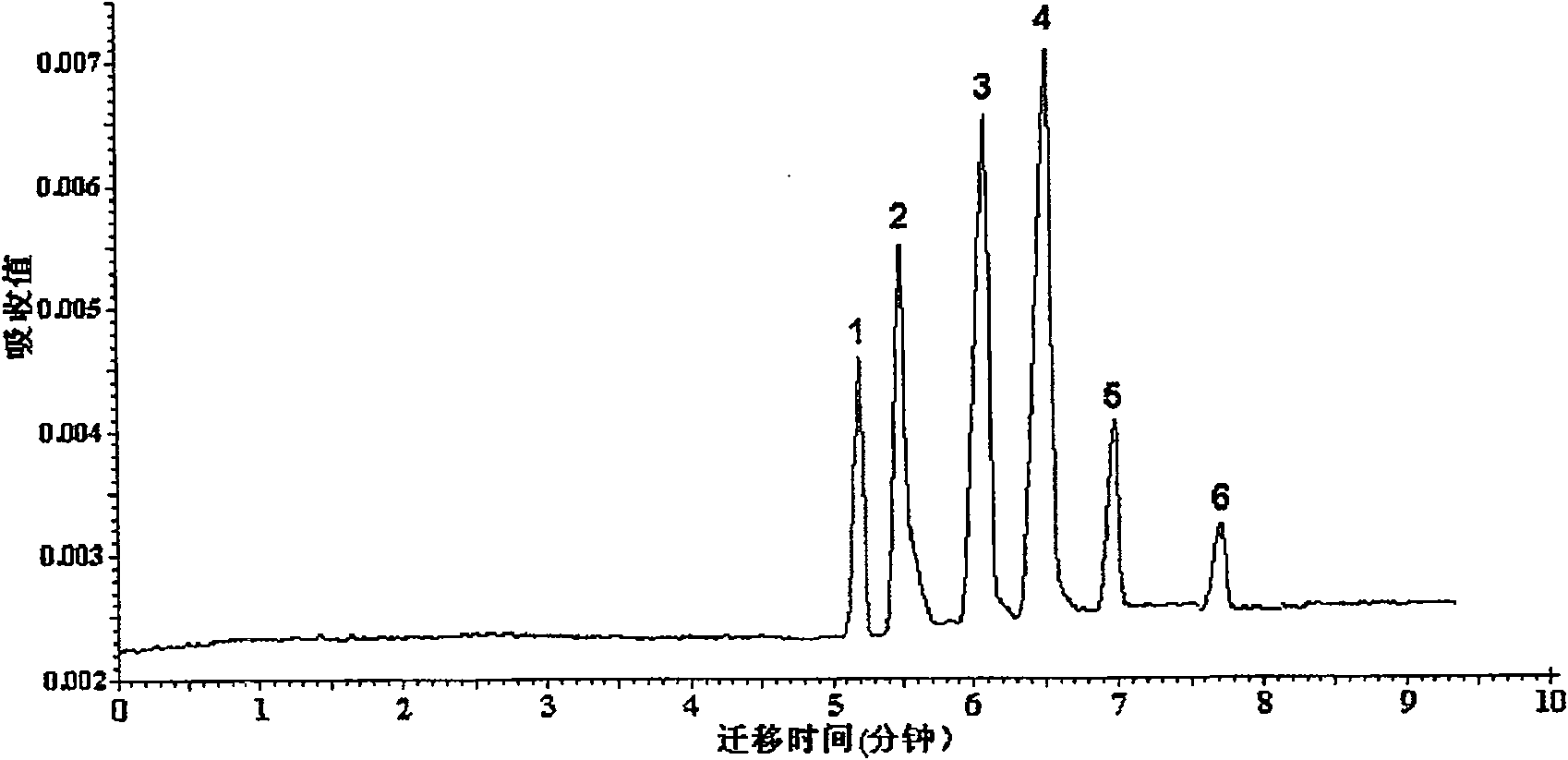

[0014] First, 30% (v / v) glycidyl methacrylate, 10% (v / v) ethylene glycol dimethacrylate, 20% (v / v) 1,4-butanediol, 30% (v / v) of n-propanol and 10% (v / v) of secondary water are fully mixed, then add azo Diisobutyronitrile, homogenize the resulting solution with N 2 The oxygen was purged to remove the oxygen and mixed into a homogeneous phase. The homogeneous solution obtained above was injected into a capillary with an inner diameter of 100 μm, and then sealed at both ends and placed in a water bath at 50°C for 20 hours to react. After the reaction is completed, the capillary is taken out and the seal is cut off, and the residual reaction solution is washed away with acetonitrile and methanol to obtain an unmodified polymer monolithic column. Inject a 3% (w / v) methanol solution of macrocyclic polyamines containing 1,4,10,13,16-pentaazatricyclohexacane-9,17-dione into the above-mentioned monolithic In the capillary, then seal the capillary and place it in a constant temperatur...

Embodiment 2

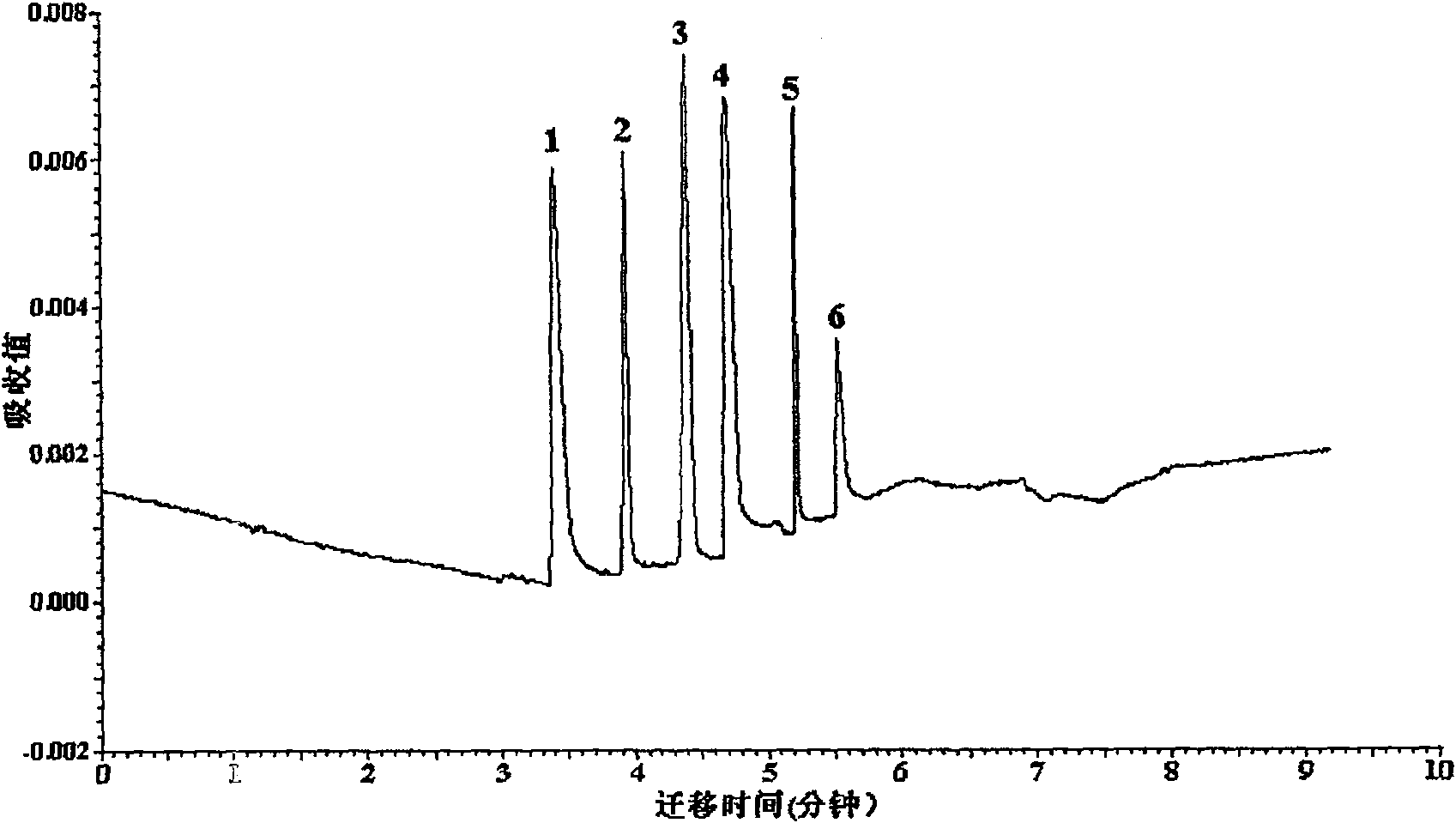

[0016] First, 40% (v / v) glycidyl methacrylate, 15% (v / v) ethylene glycol dimethacrylate, 15% (v / v) 1,4-butanediol, After fully mixing 25% (v / v) of n-propanol and 5% (v / v) of secondary water, add azobis Isobutyronitrile, the resulting solution was homogenized by ultrasonic oscillation and then washed with N 2 The oxygen is purged to remove the oxygen and it is mixed into a homogeneous phase. The homogeneous solution obtained above was injected into a capillary with an inner diameter of 100 μm, and then both ends of the capillary were sealed and placed in a water bath at 60° C. for 16 hours to react. After the reaction is completed, the capillary is taken out and the seal is cut off, and the residual reaction solution is washed away with acetonitrile and methanol to obtain an unmodified polymer monolithic column. Inject a 12% (w / v) methanol solution of macrocyclic polyamines containing 1,4,10,13,16-pentaazatricyclohexacane-9,17-dione into the above-mentioned monolithic In the...

Embodiment 3

[0018] First, 35% (v / v) of glycidyl methacrylate, 12% (v / v) of ethylene glycol dimethacrylate, 18% (v / v) of 1,4-butanediol, 30% (v / v) of n-propanol and 5% (v / v) of secondary water are fully mixed, and then add azobis Isobutyronitrile, the resulting solution was homogenized by ultrasonic oscillation and then washed with N 2 The oxygen is purged to remove the oxygen and it is mixed into a homogeneous phase. The homogeneous solution obtained above was injected into a capillary with an inner diameter of 100 μm, and then both ends of the capillary were sealed and placed in a water bath at 50° C. for 20 hours to react. After the reaction is completed, the capillary is taken out and the seal is cut off, and the residual reaction solution is washed away with acetonitrile and methanol to obtain an unmodified polymer monolithic column. Inject the macrocyclic polyamine methanol solution containing 1,4,10,13,16-pentaazatricyclohecodecane-9,17-dione 3% (w / v) into the above-mentioned inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com