Perfluorooctane sulfonic acid molecularly imprinted polymer as well as preparation method and application thereof

A perfluorooctane sulfonic acid and molecular imprinting technology, applied in the field of separation and analysis, can solve the problems such as the specificity and adsorption performance of molecularly imprinted polymers need to be improved, and achieve universality, high sensitivity, and easy large-scale production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

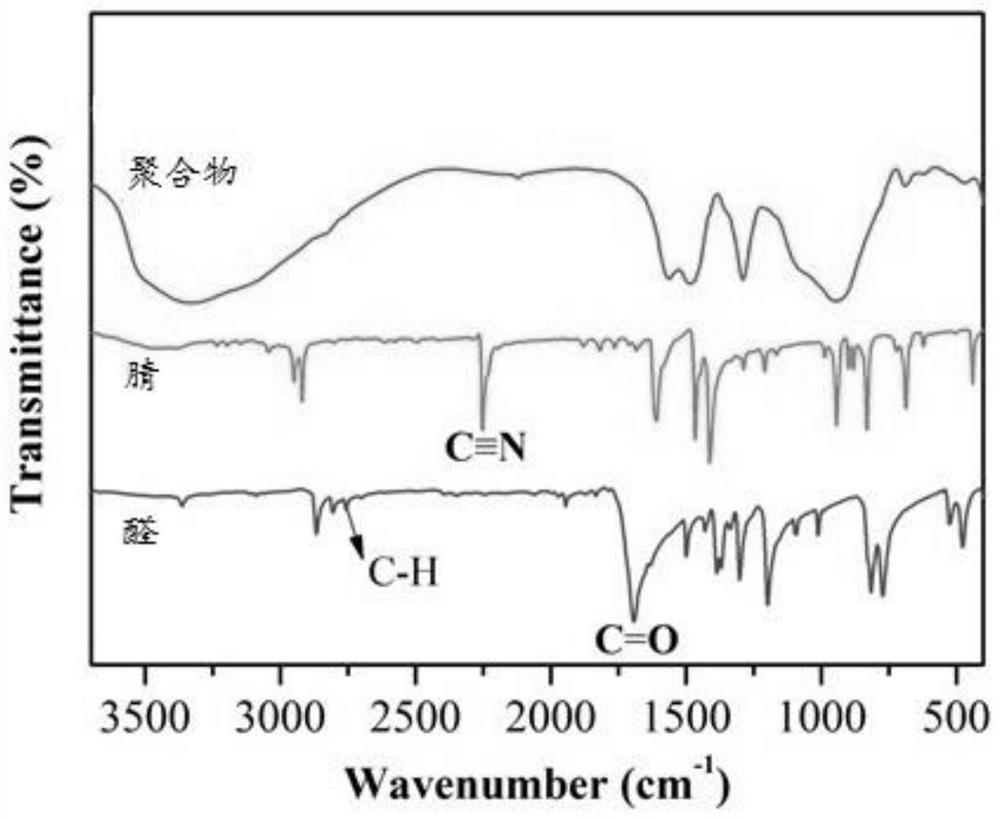

[0051] Preparation of Molecularly Imprinted Polymers:

[0052] (1) material preparation

[0053] Each raw material component is formulated according to the following dosage ratio: template perfluorooctane sulfonic acid 250.0mg (0.5mmol), functional monomer 1,4-benzenediacetonitrile 78mg (0.5mmol), functional monomer 1,4-bis( 95.5 mg (0.33 mmol) of 4-formylphenyl)benzene, 8.6 mg of catalyst sodium hydroxide, and 5 mL of porogen n-butanol.

[0054] (2) Preparation of molecularly imprinted polymers with template molecules

[0055] Add the above-mentioned prepared reactants into the test tube and mix evenly, ultrasonically degas for 15 minutes, seal and polymerize in a constant temperature oil bath at 105°C for 24 hours to obtain a polymer with template molecules;

[0056] (3) Preparation of molecularly imprinted polymers that remove template molecules

[0057] Grind the polymer prepared above through a 200-mesh sieve to obtain polymer particles with template molecules, elute w...

Embodiment 2

[0061] Preparation of Molecularly Imprinted Polymers:

[0062] (1) material preparation

[0063] Each raw material component is formulated according to the following dosage ratio: template perfluorooctane sulfonic acid 250.0mg (0.5mmol), functional monomer 1,4-benzenediacetonitrile 130mg (0.83mmol), functional monomer 1,4-bis( 95.5 mg (0.33 mmol) of 4-formylphenyl)benzene, 7.6 mg of catalyst sodium hydroxide, and 5 mL of porogen o-dichlorobenzene.

[0064] (2) Preparation of molecularly imprinted polymers with template molecules

[0065] Add the above prepared reactants into the test tube and mix evenly, ultrasonically degas for 10 minutes, seal and polymerize in a constant temperature oil bath at 110°C for 24 hours to obtain a polymer with template molecules;

[0066] (3) Preparation of molecularly imprinted polymers that remove template molecules

[0067] The polymer prepared above was ground through a 200-mesh sieve to obtain polymer particles with template molecules, wh...

Embodiment 3

[0071] Preparation of Molecularly Imprinted Polymers:

[0072] (1) material preparation

[0073] Each raw material component is formulated according to the following dosage ratio: template perfluorooctane sulfonic acid 250.0mg (0.5mmol), functional monomer 1,4-benzenediacetonitrile 104mg (0.67mmol), functional monomer 1,4-bis( 95.5 mg (0.33 mmol) of 4-formylphenyl)benzene, 7.5 mg of catalyst sodium hydroxide, and 5 mL of porogen o-dichlorobenzene.

[0074] (2) Preparation of molecularly imprinted polymers with template molecules

[0075] Add the above prepared reactants into the test tube and mix evenly, ultrasonically degas for 12 minutes, seal and polymerize in a constant temperature oil bath at 120°C for 18 hours to obtain a polymer with template molecules;

[0076] (3) Preparation of molecularly imprinted polymers that remove template molecules

[0077] The polymer prepared above was ground through a 200-mesh sieve to obtain polymer particles with template molecules, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com