Plasma display

A plasma display and phase separation technology, applied in solid cathode parts, cold cathode tubes, etc., can solve the problems of poor bonding between carbon nanotube layers and MgO layers, low working efficiency, easy to fall off, etc., to improve driving efficiency, reduce Manufacturing costs and the effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

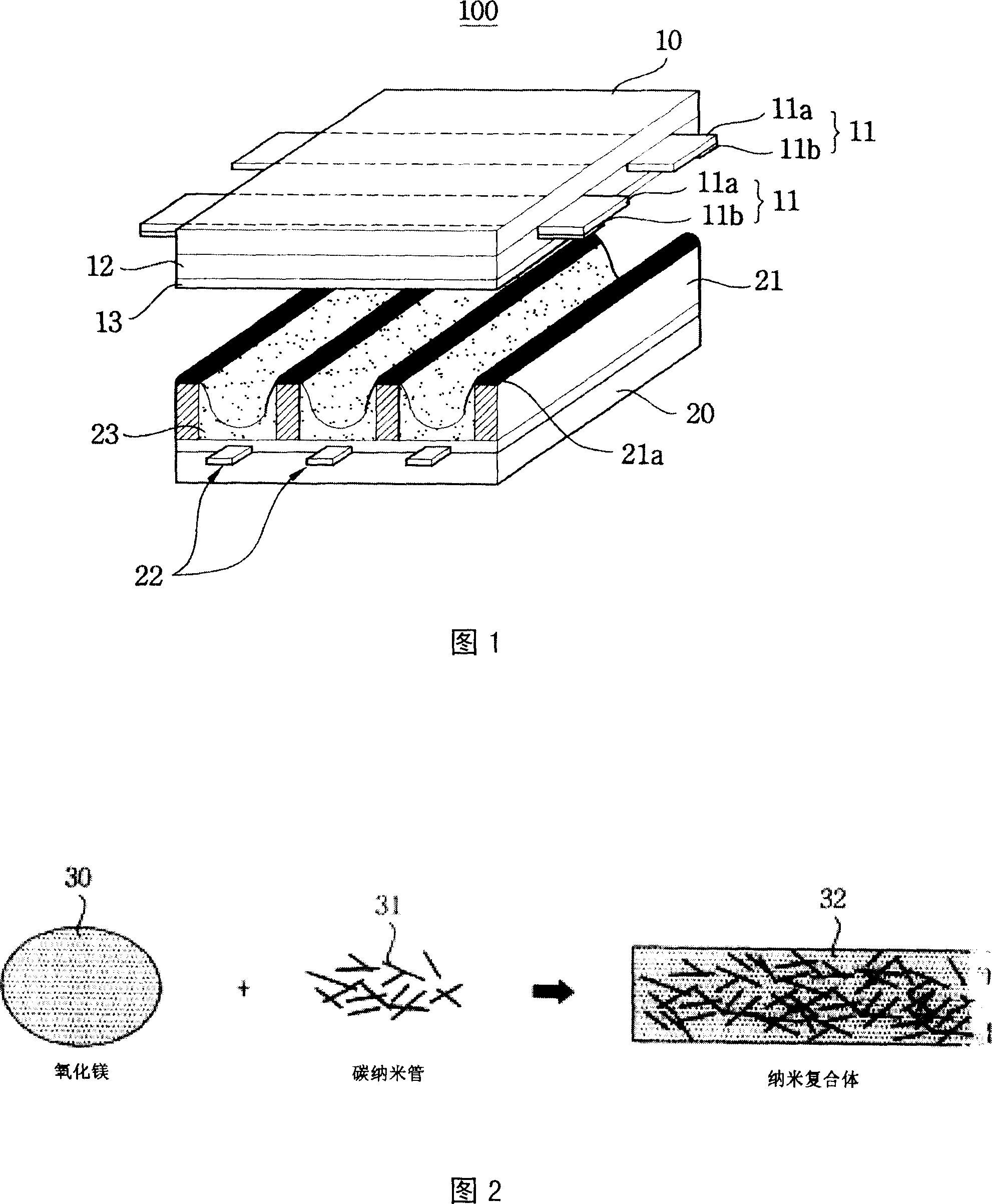

[0039] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0040]

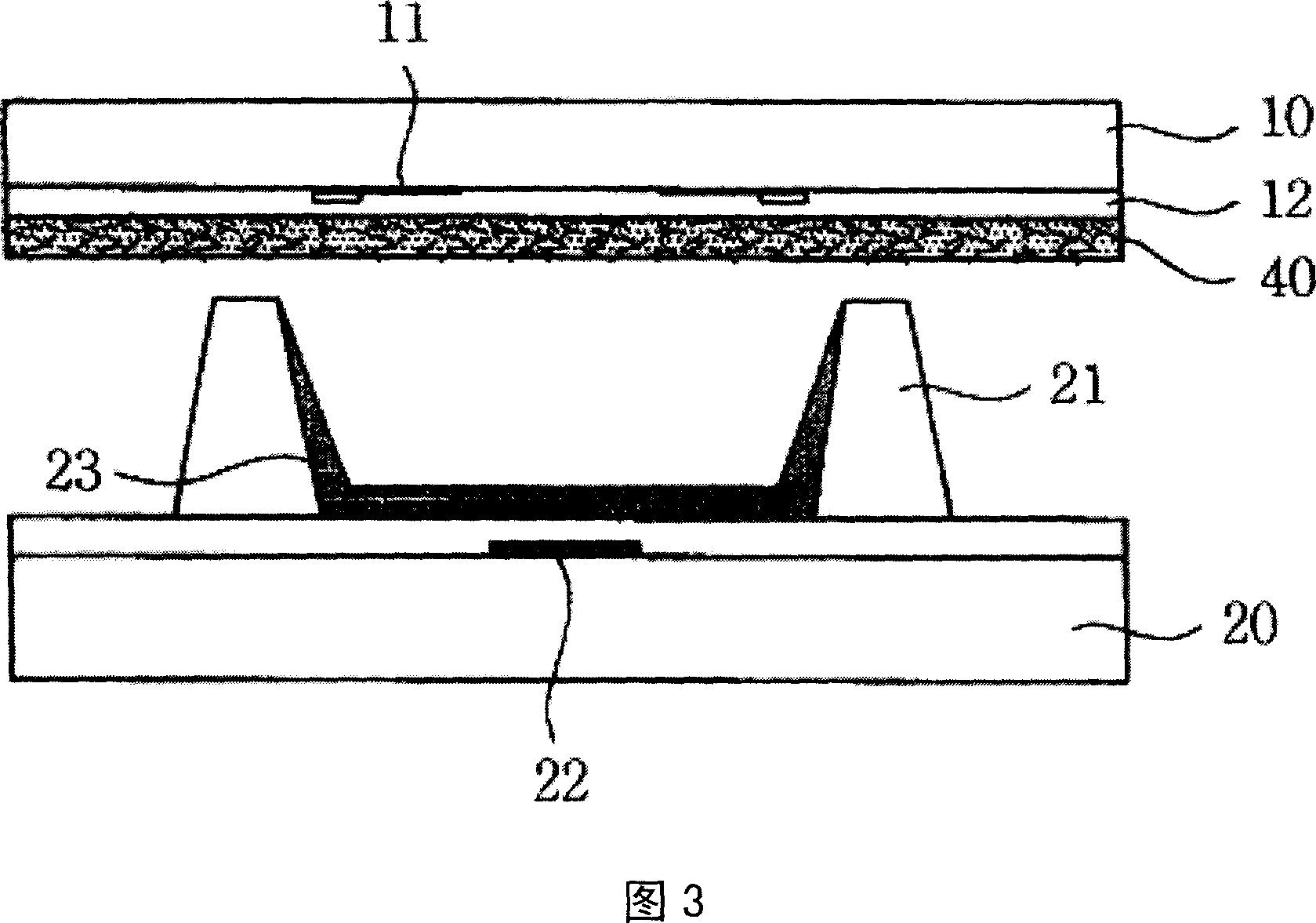

[0041] Fig. 2 is a conceptual diagram of formation of a nanocomposite using carbon nanotubes and MgO.

[0042] As shown in Fig. 2, the MgO solution formed by the sol-gel process and the carbon nanotubes are mixed to form a nanocomposite. That is, carbon nanotubes are added to the liquid MgO material formed by the sol-gel process, and mixed so that the two materials exist uniformly in the nanocomposite to form a nanocomposite. The present invention uses the nanocomposite mentioned here as the raw material of the protective film, so the strong mechanical properties of carbon nanotubes can be used to solve the traditional problem of poor mechanical properties of the protective film. A complex is formed to form a protective film, which solves the traditional problem that the carbon nanotubes and the MgO layer are separated to form a protective fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com