A preparation method of 'Sanjin' dispersible tablets

A technology of dispersible tablet and golden cherry root, which is applied in the field of Sanjin dispersible tablet and its preparation, to achieve the effects of high bioavailability, convenient taking and fast absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

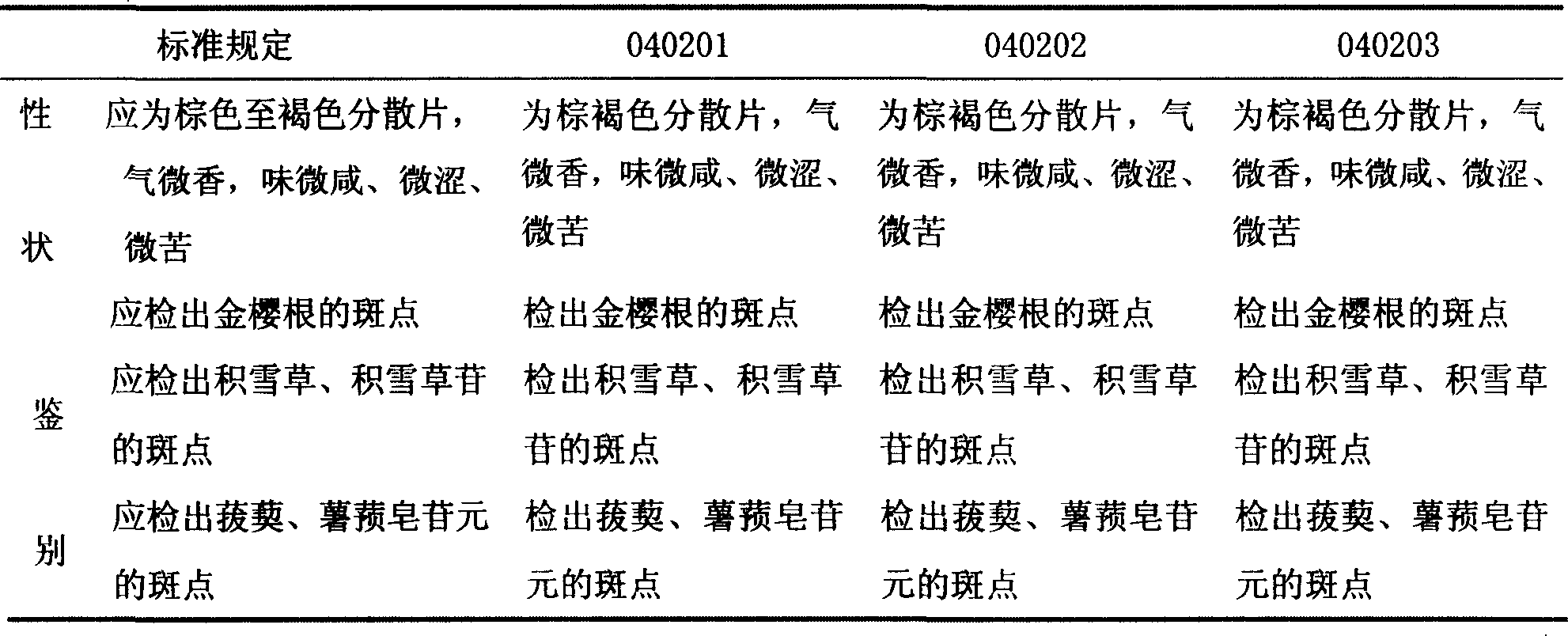

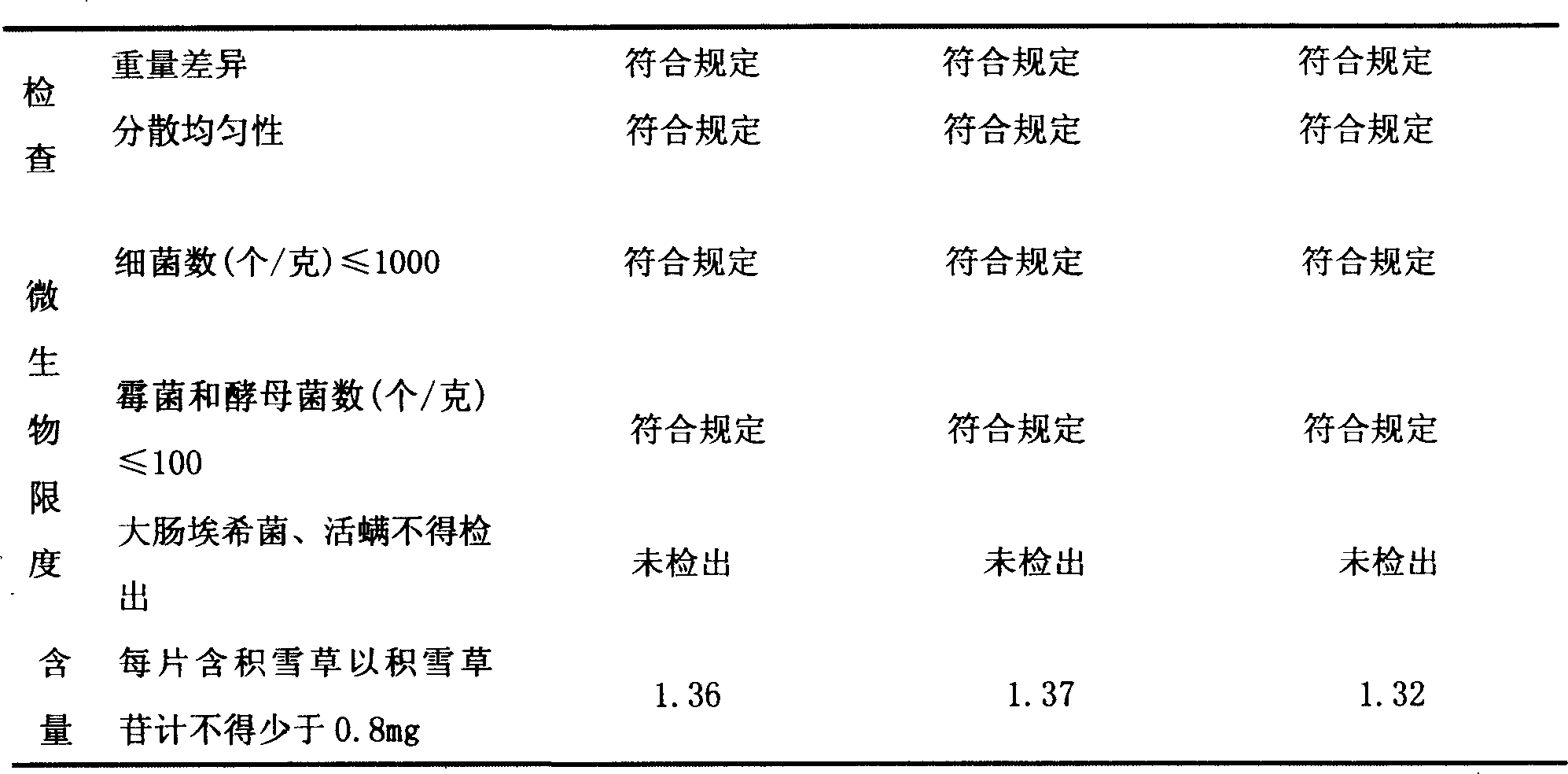

Embodiment 1

[0032] Take 2020g golden cherry root, 1010g sarsaparilla, 1010g sheep opening, 606g Jinsha rattan, 606g centella asiatica, add water to decoct twice, add 12 times of water for the first time, decoct for 2 hours; add 10 times of water for the second time, decoct 1 hour; combine the decoction, filter, and the filtrate adopts the method of three-effect decompression concentration (temperature: first effect 92°C, second effect 84°C, third effect 73°C; vacuum degree: first effect-0.03Mpa, second effect-0.05 Mpa, three-effect -0.07 Mpa) concentrated to the relative density of 1.15 ~ 1.20 (60 ℃) extract, spray drying under the conditions of the inlet air temperature of 155 ~ 160 ℃, the outlet air temperature of 75 ~ 80 ℃, it is dry Extract powder 265 g, weigh 213 g of micropowder silica gel, 73 g of sodium starch glycolate and mix evenly, granulate with 70% ethanol, dry, add 2 g of magnesium stearate and 47 g of sodium starch glycolate to the dry granules, mix evenly, and press into 1...

Embodiment 2

[0034] Take 20.2kg of golden cherry root, 10.1kg of sarsaparilla, 10.1kg of sheep opening, 6.06g of golden sand vine, 6.06g of centella asiatica, add water to decoct three times, add 10 times the water for the first time, and decoct for 2 hours; add 8 times the water for the second and third times Double the water, decoct for 1 hour each; combine the decoction, filter, and the filtrate adopts the method of three-effect decompression concentration (temperature: first effect 90°C, second effect 80°C, third effect 70°C; vacuum degree: first effect-0.04 Mpa, second effect -0.06Mpa, third effect -0.08 Mpa) concentrated to the extract with a relative density of 1.12~1.17 (60°C), use micropowder silica gel 1.21kg as the base material, spray into the extract, and the spray pressure is 0.08~ One-step granulation under the conditions of 0.09Mpa, material temperature of 70-75°C, inlet air temperature of 95-98°C, outlet air temperature of 85-86°C, and drying temperature of 65-70°C, and the...

Embodiment 3

[0036] Take 20.2kg of golden cherry root, 10.1kg of sarsaparilla, 10.1kg of sheep opening, 6.06g of golden sand vine, 6.06g of centella asiatica, add water to decoct three times, add 9 times the water for the first time, and decoct for 2 hours; add 7 times the water for the second and third times Double the water, decoct for 1 hour each; combine the decoction, filter, and the filtrate adopts the method of three-effect decompression concentration (temperature: first effect 86°C, second effect 78°C, third effect 68°C; vacuum degree: first effect-0.05 Mpa, second effect -0.07Mpa, third effect -0.09Mpa) concentrated to the extract with a relative density of 1.18~1.20 (60°C), use micropowder silica gel 2.10kg as the base material, spray into the extract, and the spray pressure is 0.12~ Carry out one-step granulation under the conditions of 0.14Mpa, material temperature of 65-70°C, inlet air temperature of 103-105°C, outlet air temperature of 82-84°C, and drying temperature of 75-85°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com