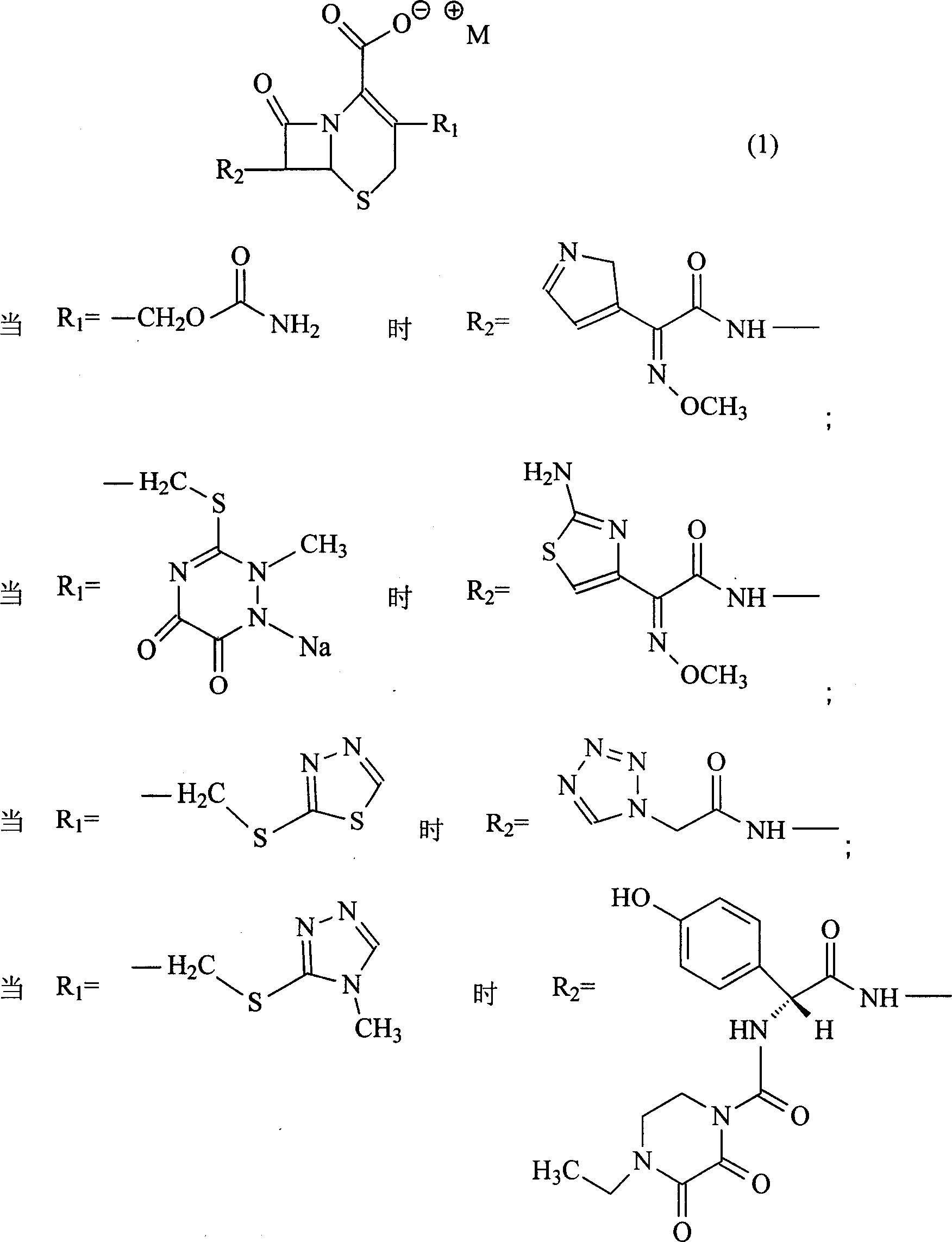

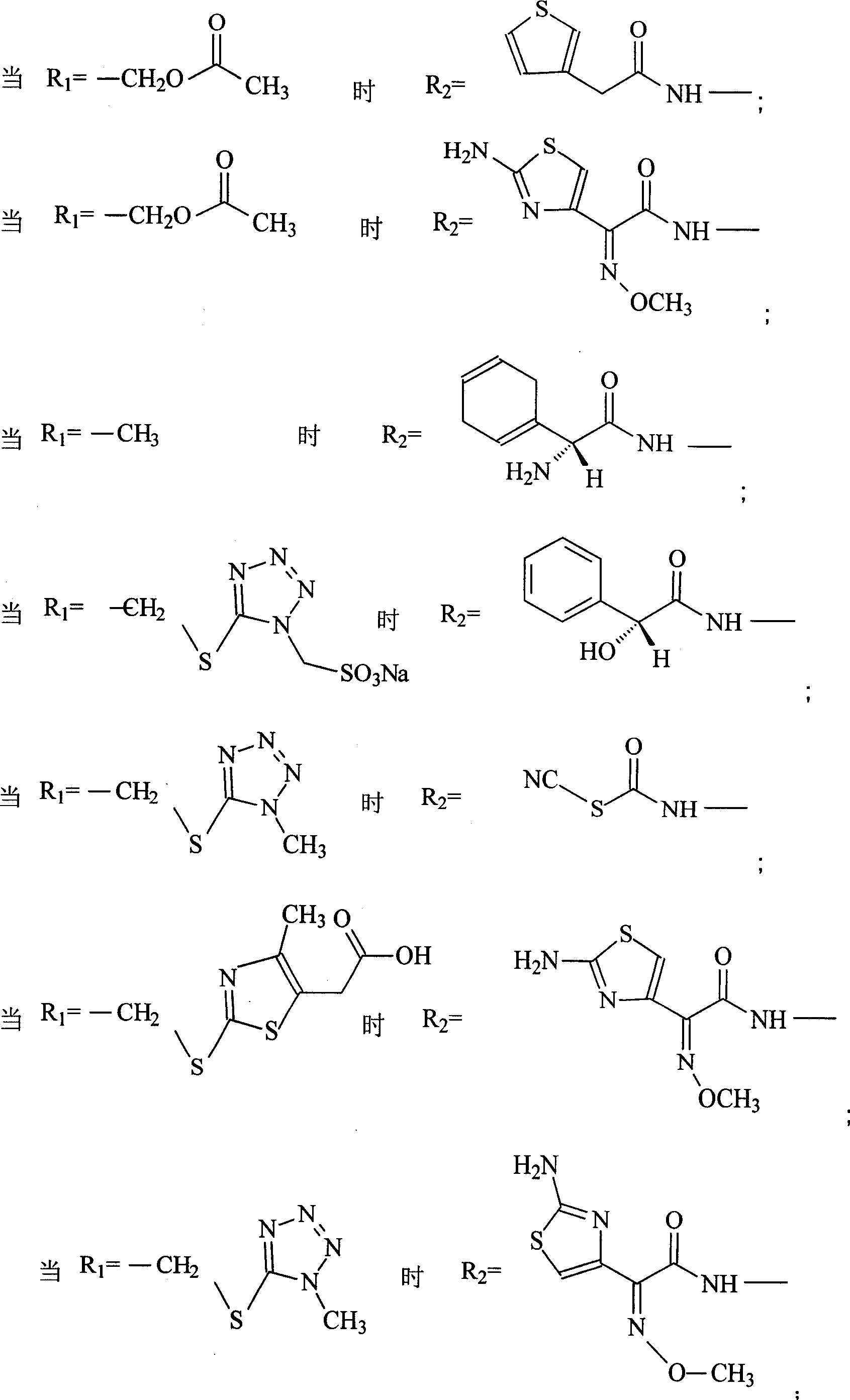

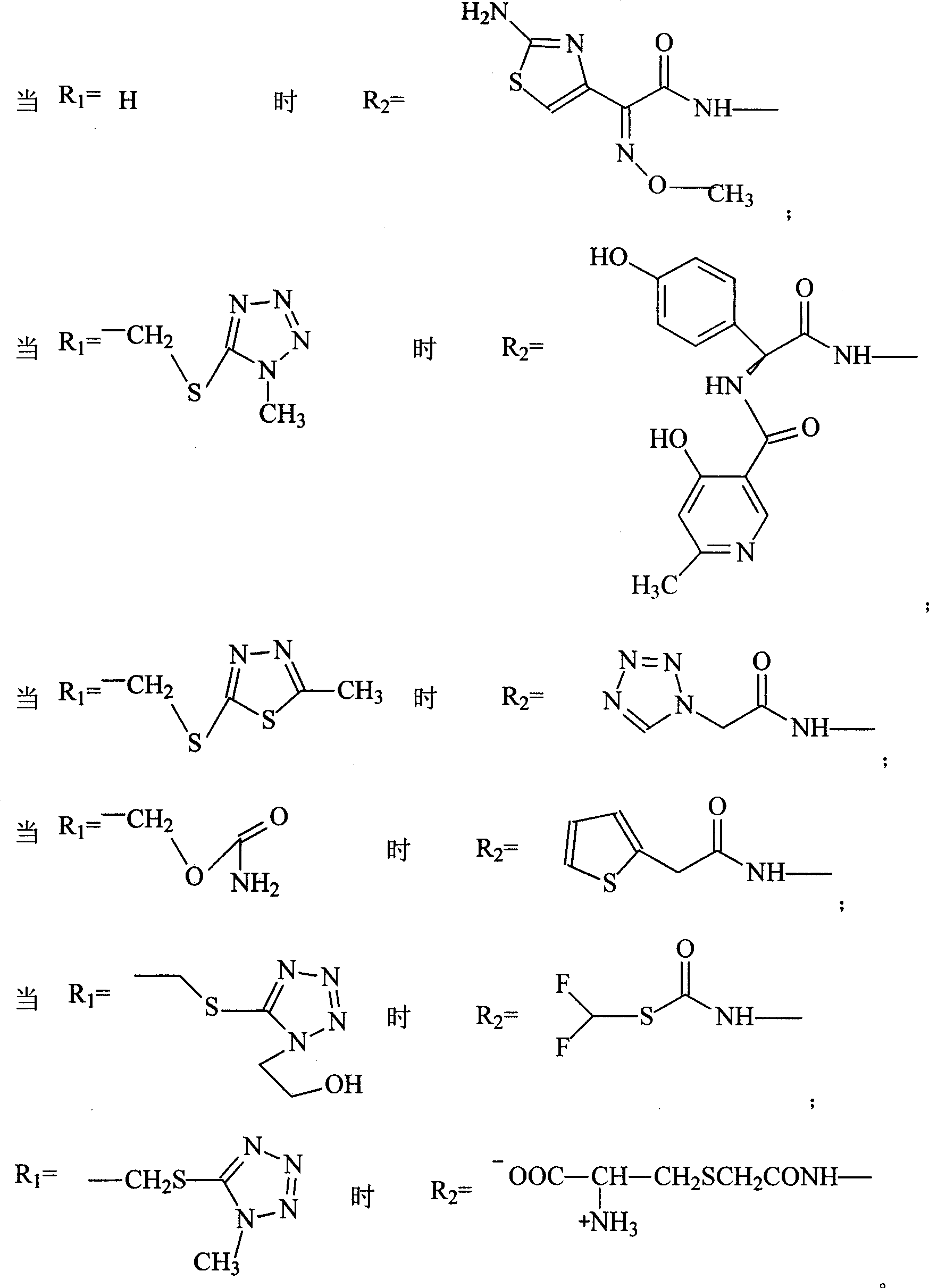

Organic amine salt of cephalosporin compound and its preparation method

A technology of organic amine salts and cephalosporins, which is applied in the field of derivatives of cephalosporins and their preparation, and can solve problems such as incompatibility, adverse reactions, and hypernatremia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1: Preparation of Cefuroxime Arginine

[0054] Add 17.4g (0.1mol) of arginine and 20ml of 60% ethanol into a 250ml three-necked flask, add 42.4g (0.1mol) of cefuroxime acid in 20ml 80% ethanol solution under high temperature stirring, and stir until the mixture is clear. After stirring for 2 hours at room temperature, the mixed reactants were dropped into 300ml (5-10℃) acetone solution to obtain white powdery crystals. The solid powder was filtered with suction, and the solid was washed with a small amount of acetone. Under vacuum drying conditions for 24 hours, 53.0 g of powdered solids were obtained, with a yield of 88.7%. Content analysis: (HPLC method) containing 70.2-71.4% of cefuroxime acid. NMR, MS, UV, IR and HPLC analysis showed that the product was cefuroxime arginine salt with a purity of 99.3%.

Embodiment 2

[0055] Example 2: Preparation of ceftriaxone arginine

[0056] In a 250ml three-necked flask, add 17.4g (0.1mol) of arginine, 4ml of methanol, and 2ml of water. Stir at high temperature. Add 57.7g (0.1mol) of ceftriaxone. Drop into 500ml of acetone at high temperature to precipitate a large amount of white crystalline powder, filter the solid with a small amount of acetone, and dry at high temperature under phosphorus pentoxide for 24 hours to obtain 67.2g of white crystalline ceftriaxone arginine salt. Yield: 89.8%, content analysis (HPLC method): 76.1-77.3% containing ceftriaxone acid. NMR, MS, UV, IR and HPLC analysis showed that the product was ceftriaxone arginine salt with a purity of 99.4%.

Embodiment 3

[0057] Example 3: Preparation of Cefotizole Arginine

[0058] In a 250ml three-necked flask, add 17.4g (0.1mol) of arginine, 4ml of methanol, and 2ml of water. Stir at high temperature. Add 44g (0.1mol) of cefotiazole. Stir to dissolve and stir for another 1 hour. Put the mixture at high temperature. Drop it into 500ml of acetone to precipitate a large amount of white crystalline powder, filter the solid with a small amount of acetone, and dry it at high temperature under phosphorus pentoxide for 24 hours to obtain 54.5g of white crystalline cefotizole arginine salt. Yield: 88.8%, content analysis (HPLC method): containing 71.2-72.2% of cefotizolic acid. NMR, MS, UV, IR and HPLC analysis showed that the product was cefotizole arginine salt with a purity of 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com