Forcipated diimidazoline palladium compound and its application in Suzuki reaction

A technology of bis-imidazoline and palladium compounds, which is applied in the field of pincer-shaped bis-imidazoline palladium compounds and its catalytic application in Suzuki reaction, can solve the problems of high toxicity of phosphine ligands, inconvenient operation, poor stability, etc., and achieve special reaction Strong performance, little impact on the environment, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

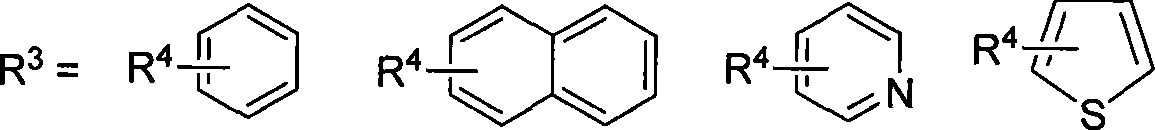

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Preparation of 2,6-bis(4,5-dihydro-1-p-methoxyphenyl-1H-imidazol-2-yl)phenylpalladium(II) chloride: under reflux with stirring Add 1,3-bis(4,5-dihydro-1-p-methoxyphenyl-1H-imidazol-2-yl)benzene (0.43g, 1mmol) and palladium acetate (0.27g , 1.2mmol) and 60mL of glacial acetic acid, protected from light, stirred and refluxed under nitrogen atmosphere for two days, steamed out glacial acetic acid, then added 50mL of acetone / water solution of lithium chloride (0.42g, 10mmol), the volume ratio of acetone to water was Acetone: water = 3: 2 (the same below), stirred at room temperature for two days, extracted with dichloromethane (3 times, 30 mL each time), combined the organic phases, washed with saturated brine, anhydrous MgSO 4 Dry, evaporate solvent under vacuum, utilize the volume ratio of acetone and dichloromethane to be acetone: the acetone / dichloromethane mixed solvent of dichloromethane=1: 1 is made developing solvent, thin-layer chromatographic separation...

Embodiment 2

[0025] Example 2: 2,6-bis[(S)-4-isopropyl-4,5-dihydro-1-p-tolyl-1H-imidazol-2-yl]phenylpalladium(II) chloride Preparation: Add 1,3-bis[(S)-4-isopropyl-4,5-dihydro-1-p-tolyl-1H-imidazol-2-yl to a 100mL three-neck flask equipped with a stirring reflux device ] Benzene (0.48 g, 1 mmol), palladium acetate (0.23 g, 1 mmol) and 60 mL of glacial acetic acid, protected from light, stirred and refluxed under a nitrogen atmosphere for one day, evaporated glacial acetic acid, and then added lithium chloride (0.50 g, 12 mmol) Acetone / water solution 50mL, stirred at room temperature for one day, extracted with dichloromethane (3 times, 30mL each time), combined organic phases, washed with saturated brine, anhydrous MgSO 4Dry, evaporate the solvent under vacuum, use the acetone / dichloromethane mixed solvent whose volume ratio of acetone and dichloromethane is acetone: dichloromethane=1:50 as developing solvent, and separate the product by thin layer chromatography to obtain the product, nam...

Embodiment 3

[0026] Embodiment 3: 2,6-bis[(S)-4-isopropyl-4,5-dihydro-1-p-methoxyphenyl-1H-imidazol-2-yl]phenylpalladium chloride ( II) Preparation: add 1,3-bis[(S)-4-isopropyl-4,5-dihydro-1-p-methoxyphenyl-1H to a 100mL three-necked flask equipped with a stirring reflux device -imidazol-2-yl]benzene (0.51g, 1mmol), palladium acetate (0.34g, 1.5mmol) and 60mL of glacial acetic acid, protected from light, stirred and refluxed under nitrogen atmosphere for 4 days, evaporated the glacial acetic acid, and then added chlorinated acetic acid Lithium (0.63 g, 15 mmol) in 50 mL of acetone / water solution, stirred at room temperature for 4 days, extracted with dichloromethane (3 times, 30 mL each), combined organic phases, washed with saturated brine, anhydrous MgSO 4 Dry, evaporate the solvent under vacuum, use the acetone / dichloromethane mixed solvent whose volume ratio of acetone and dichloromethane is acetone: dichloromethane=1:70 as developing solvent, and separate the product by thin layer chr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com