Y2 O3 nanometer carrier Ag catalyst, its synthesis and use

A synthesis method and catalyst technology, which are applied in the field of new high-efficiency catalysts for in-situ supported Ag nanocrystals on single crystal Y2O3 nanobelts, can solve the problems of easy accumulation of hydroxylamine, potential safety hazards, low activity and selectivity, etc. The effect of shortened time, simple and safe operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In a clean and dry 250 ml round bottom flask or three-necked flask, add 2.05 g of yttrium nitrate hexahydrate (Y(NO 3 ) 3 .6H 2 O) solid, 10 milliliters of dodecylamine and 10 milliliters of octadecene, then rise to 320 ℃ with the rate of 8 ℃ per minute from room temperature, after reacting for 20 minutes, add 100 milligrams of silver nitrate (AgNO 3 ) solid, after continuing to react for 10 minutes, turn off the heating source and cool down to room temperature naturally. Disperse the product with 20 milliliters of n-heptane or n-hexane, then add 10 milliliters of absolute ethanol for precipitation, and finally centrifuge, repeat this operation 3-7 times, and vacuum-dry the final product at 60°C for 4 hours for use in Analysis and Characterization.

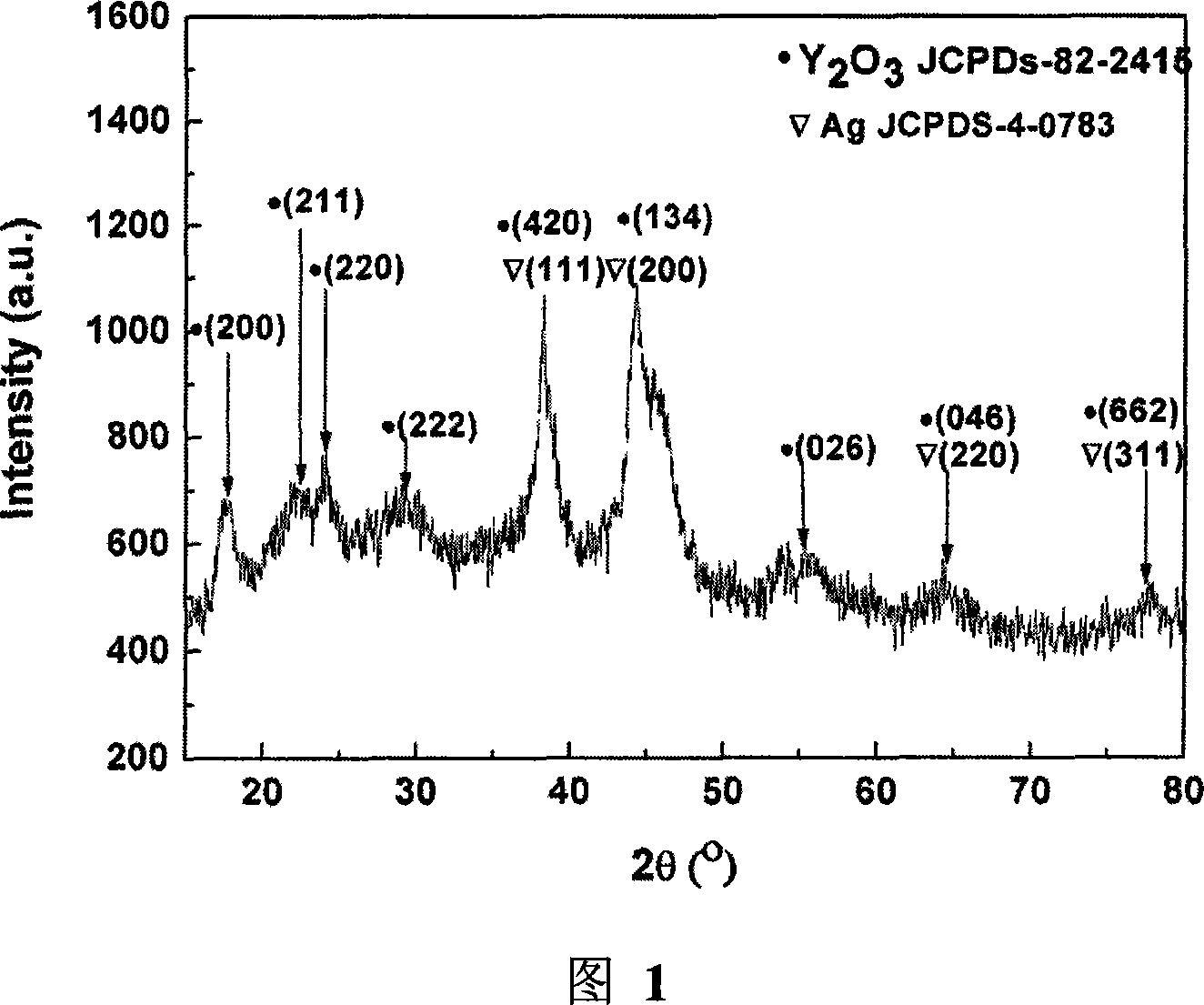

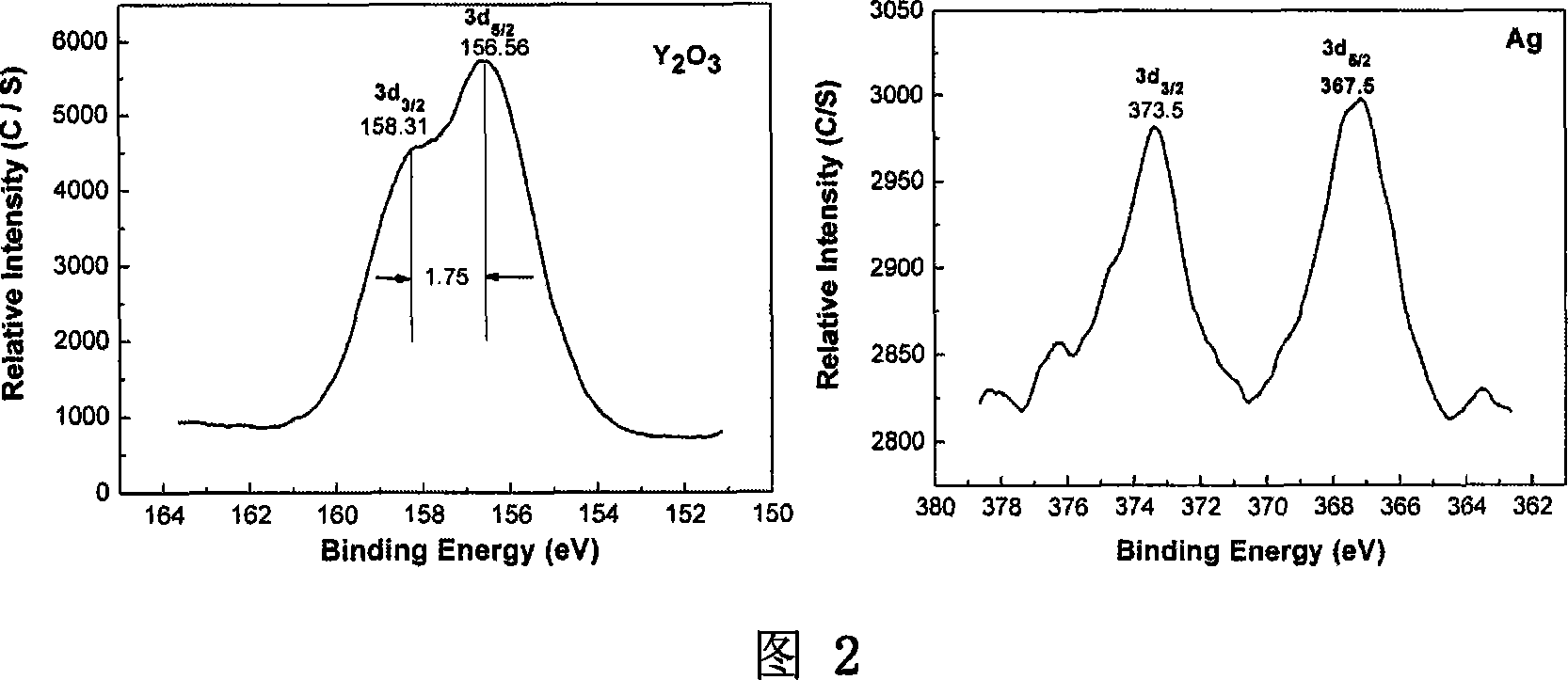

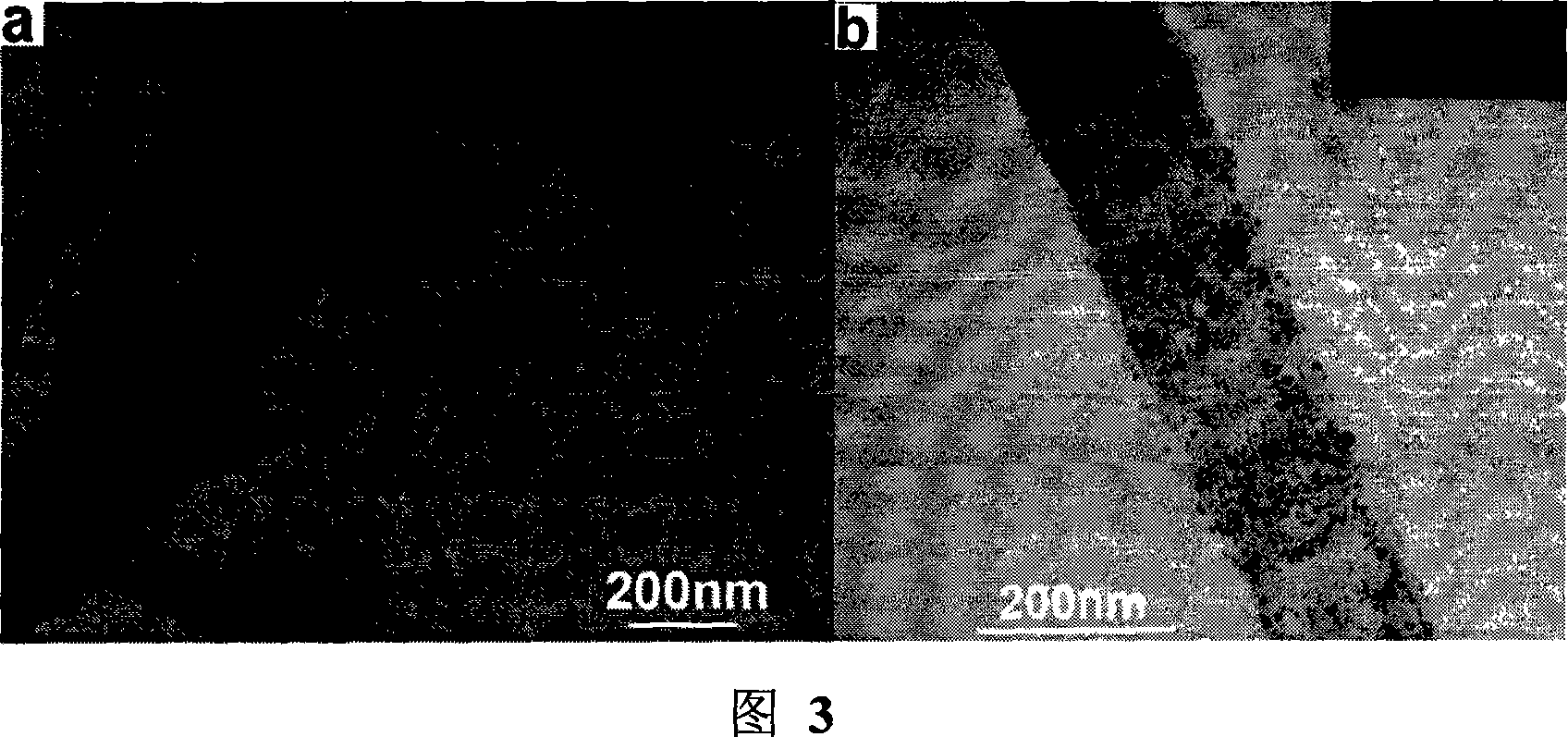

[0029] The components and phase structure of the product were analyzed by X-Ray powder diffraction (Fig. 1), which proved that there was Y in the product. 2 o 3 and Ag two components. X-Ray photoelectron spectroscopy ...

Embodiment 2

[0034] In a clean and dry 250 ml round bottom flask or three-necked flask, add 1.58 g of yttrium nitrate hexahydrate (Y(NO 3 ) 3 .6H 2 O) solid, 6 milliliters of dodecylamine and 8 milliliters of octadecene liquid, then the reactor was raised to 310 DEG C at a rate of 12 DEG C per minute from room temperature, and after 15 minutes of reaction, 30 milligrams of silver nitrate (AgNO 3 ) solid, after continuing to react for 10 minutes, turn off the heating source and cool down to room temperature naturally. Disperse the product with 20 milliliters of n-heptane or n-hexane, then add 10 milliliters of absolute ethanol for precipitation, and finally centrifuge, repeat this operation 3-7 times, and vacuum-dry the final product at 60°C for 4 hours for use in Analysis and Characterization.

[0035] The products were analyzed and characterized by X-Ray powder diffraction, X-Ray photoelectron spectroscopy and transmission electron microscopy. Using the catalytic hydrogenation reactio...

Embodiment 3

[0037] In a clean and dry 250 ml round bottom flask or three-necked flask, add 5.0 g of yttrium nitrate hexahydrate (Y(NO 3 ) 3 ) solid, 12 milliliters of dodecylamine and 15 milliliters of octadecene liquid, then raise the reactor from room temperature to 320 degrees Celsius at a rate of 6 degrees per minute in a sand bath, and after 25 minutes of reaction, quickly add 160 milligrams of nitric acid Silver (AgNO 3 ) solid, after continuing to react for 10 minutes, turn off the heating source and cool down to room temperature naturally. Disperse the product with 20 milliliters of n-heptane or n-hexane, then add 10 milliliters of absolute ethanol for precipitation, and finally centrifuge, repeat this operation 3-7 times, and vacuum-dry the final product at 60°C for 4 hours for use in Analysis and Characterization.

[0038] The products were analyzed and characterized by X-Ray powder diffraction, X-Ray photoelectron spectroscopy and transmission electron microscopy. Using the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com