Method of preparing ethylen-propylene rubber graft polymers

A technology of grafted polymers and ethylene-propylene rubber, applied in the field of polymer chemistry, can solve the problems of uncontrollable polymer chain structure, many side reactions, and easy cross-linking, etc., to overcome the difficulty of removing the initiator, the degree of polymerization and the Effects of structural control and less side reactions in coupling reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

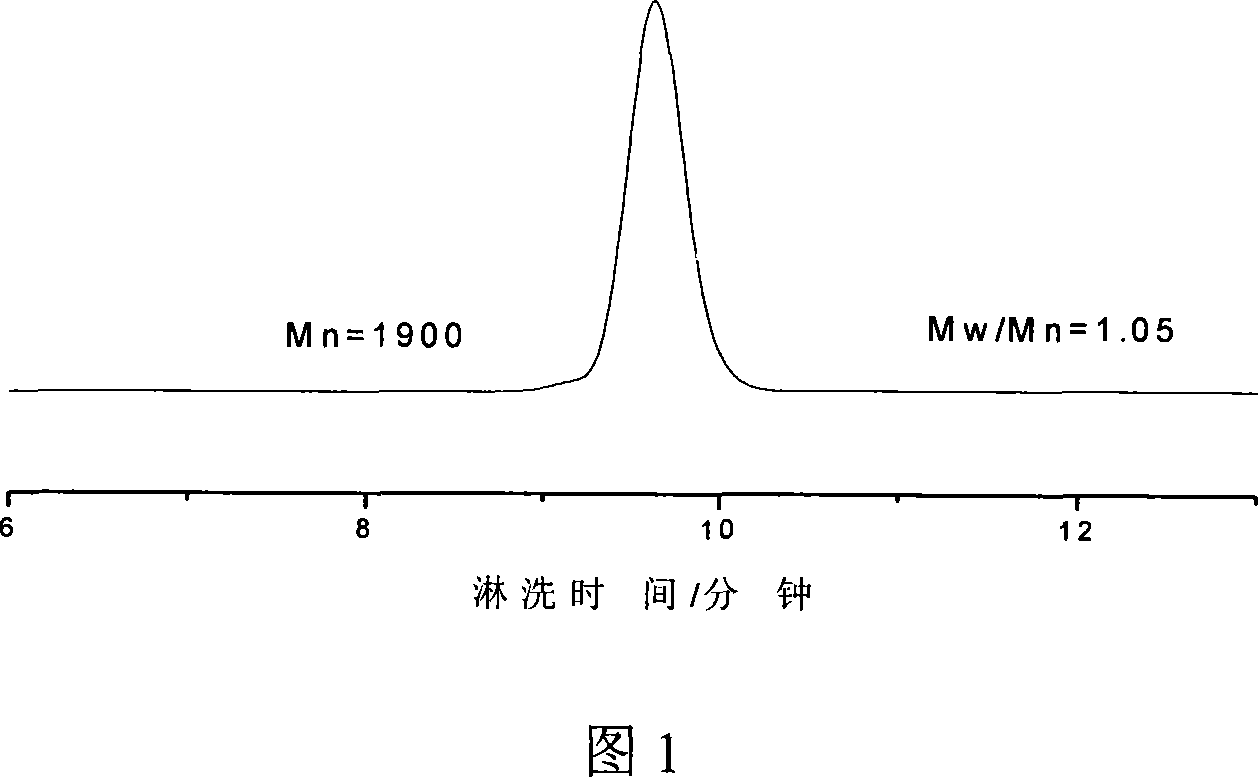

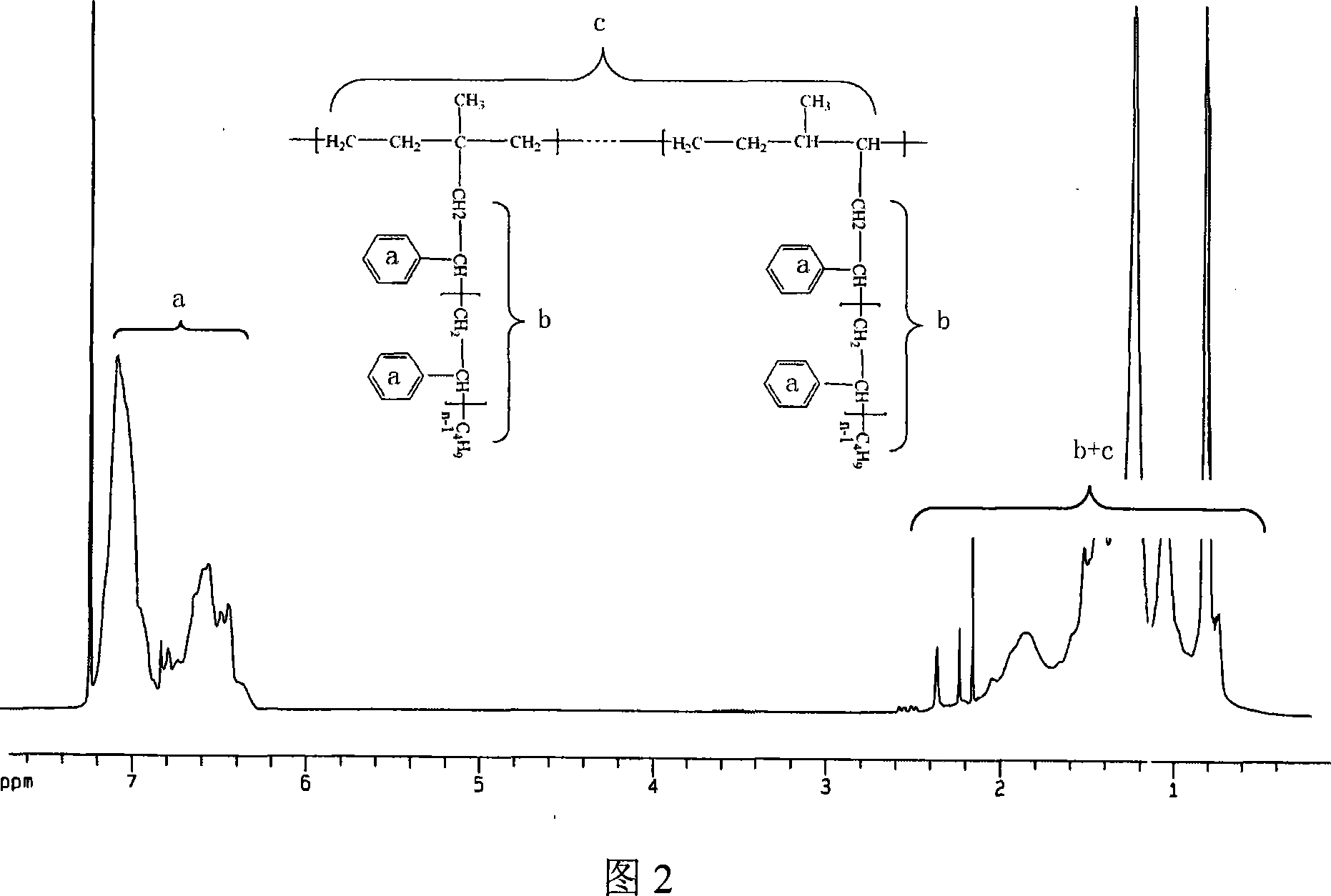

Embodiment 1

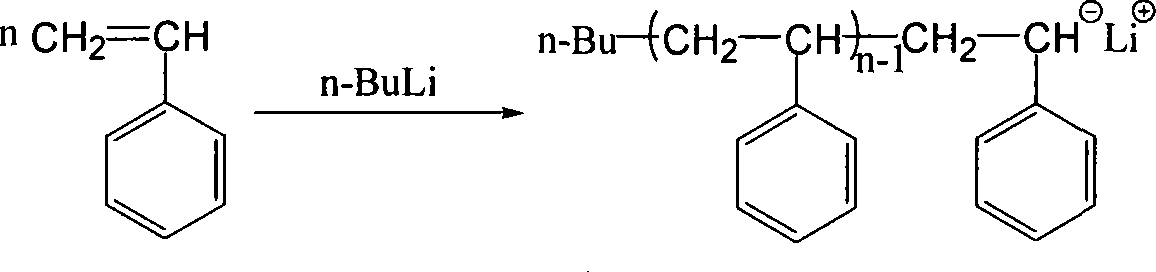

[0021] Nitrogen gas-vacuumization-gas lamp baking bottle-nitrogen gas, repeat this 3 times, and continue to nitrogen gas to maintain positive pressure in the reaction bottle. Add 0.6072g of chlorinated binary ethylene propylene rubber with a chlorine content (percentage by weight) of 12.5% and 25ml of hexanaphthene to the polymerization bottle under nitrogen protection with a pouring tube, keep positive pressure in the bottle, stir and dissolve for two days. Two days after dissolving, under the protection of nitrogen, pour the cyclohexane solution of chlorinated ethylene propylene diene rubber into another polymerization bottle with molecular sieves, pumping, baking, and filling with nitrogen three times, and let it dry for one day for later use.

[0022] Nitrogen gas-vacuumization-gas lamp baking bottle-nitrogen gas, repeat this 3 times, and continue to nitrogen gas to maintain positive pressure in the reaction bottle. Add 30 ml of cyclohexane into the reactor with a pourin...

Embodiment 2

[0026] Nitrogen gas-vacuumization-gas lamp baking bottle-nitrogen gas, repeat this 3 times, and continue to nitrogen gas to maintain positive pressure in the reaction bottle. Add 0.5944g of chlorinated binary ethylene propylene rubber with a chlorine content (percentage by weight) of 5.4% and 25ml of hexanaphthene to the polymerization bottle under nitrogen protection with a pouring tube, keep positive pressure in the bottle, stir and dissolve for two days. Two days after dissolving, under the protection of nitrogen, pour the cyclohexane solution of chlorinated ethylene propylene diene rubber into another polymerization bottle with molecular sieves, pumping, baking, and filling with nitrogen three times, and let it dry for one day for later use.

[0027] Nitrogen gas-vacuumization-gas lamp baking bottle-nitrogen gas, repeat this 3 times, and continue to nitrogen gas to maintain positive pressure in the reaction bottle. Add 25ml of cyclohexane into the reactor with a pouring tu...

Embodiment 3

[0031] Nitrogen gas-vacuumization-gas lamp baking bottle-nitrogen gas, repeat this 3 times, and continue to nitrogen gas to maintain positive pressure in the reaction bottle. Add 0.6106g of chlorinated binary ethylene propylene rubber with a chlorine content (percentage by weight) of 5.4% and 25ml of hexanaphthene to the polymerization bottle under nitrogen protection with a pouring tube, keep positive pressure in the bottle, stir and dissolve for two days. Two days after dissolving, under the protection of nitrogen, pour the cyclohexane solution of chlorinated ethylene propylene diene rubber into another polymerization bottle with molecular sieves, pumping, baking, and filling with nitrogen three times, and let it dry for one day for later use.

[0032] Nitrogen gas-vacuumization-gas lamp baking bottle-nitrogen gas, repeat this 3 times, and continue to nitrogen gas to maintain positive pressure in the reaction bottle. Add 25ml of cyclohexane into the reactor with a pouring tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grafting efficiency | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com