Method of preparing barium yttrium borate and barium yttrium borate crystal and use thereof

A barium borate and crystal technology, applied in the field of scintillation crystals and their growth, achieves the effects of sensitive response, simple equipment and mild experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] First prepare barium yttrium borate polycrystalline raw material:

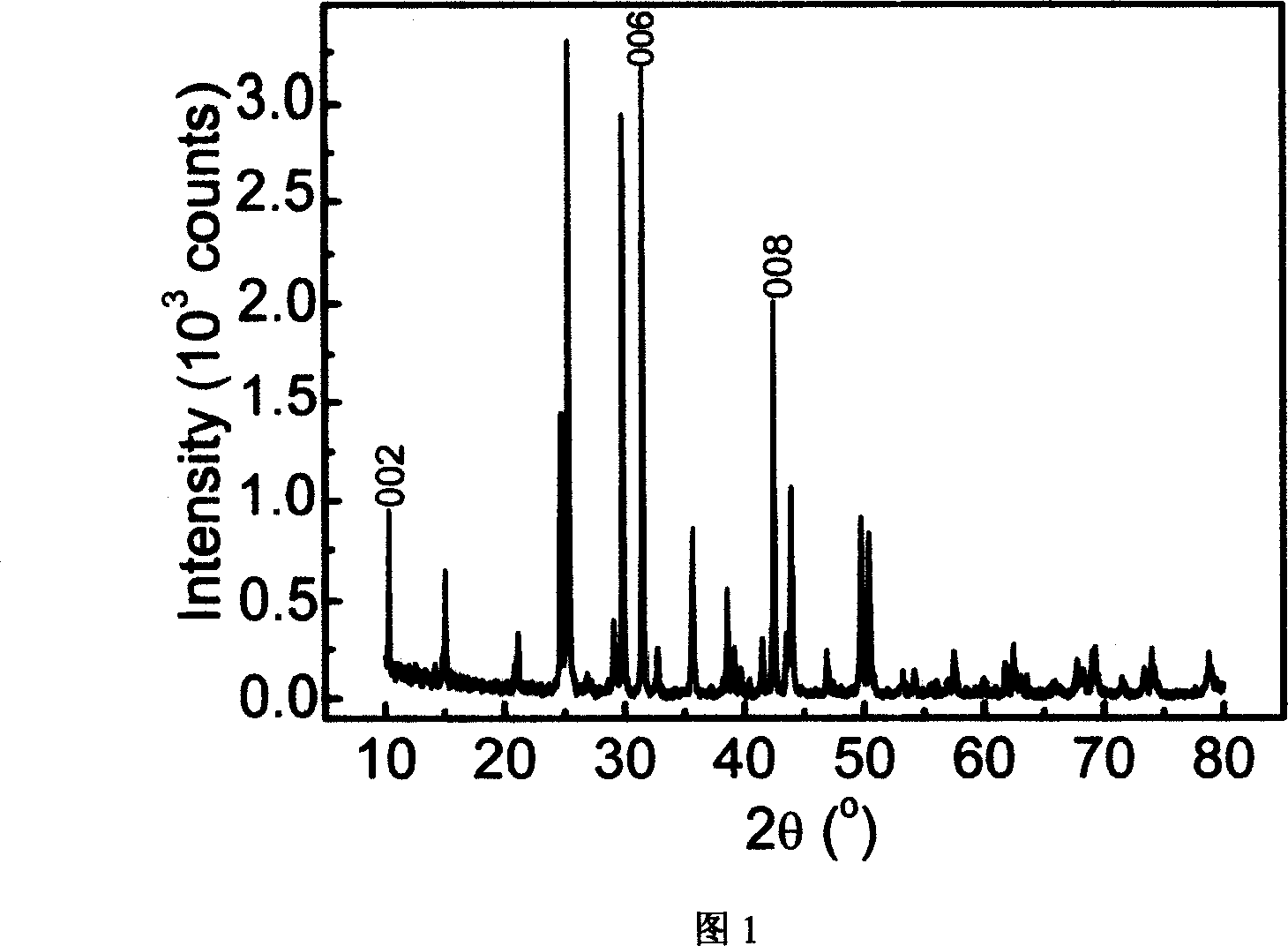

[0022] Analytical pure yttrium oxide (Y 2 o 3 ), barium carbonate (BaCO 3 ), boric acid (H 3 BO 3 ) in a molar ratio of 1:3:9.0-9.1 is ground in an agate mortar and mixed evenly, then put into a platinum crucible, put the platinum crucible into a muffle furnace, heat to 920°C and keep at this temperature for 72 Hours, grind 3 times during the heating process to make the reactants fully react in solid phase, then turn off the power, and cool the sample to room temperature with the furnace to obtain YBa 3 B 9 o 18 Polycrystalline. The X-ray diffraction spectrum of the obtained sample is shown in Figure 1, indicating that the obtained powder is barium yttrium borate. The purity of the above-mentioned analytically pure yttrium oxide, barium carbonate, and boric acid is not less than 99.9%;

[0023] Utilize above-mentioned raw material to grow and obtain barium yttrium borate single crystal:

[002...

Embodiment 2

[0026] First prepare barium yttrium borate polycrystalline raw material:

[0027] Analytical pure yttrium oxide (Y 2 o 3 ), barium carbonate (BaCO 3 ), boric acid (H 3 BO 3 ) in a molar ratio of 1:3:9.0-9.1 is ground in an agate mortar and mixed evenly, then put into a platinum crucible, put the platinum crucible into a muffle furnace, heat to 930°C and keep at this temperature for 24 Hours, grind 3 times during the heating process to make the reactants fully react in solid phase, then turn off the power, and cool the sample to room temperature with the furnace to obtain YBa 3 B 9 o 18 Polycrystalline. The X-ray diffraction spectrum of the obtained sample is shown in Figure 1, indicating that the obtained powder is barium yttrium borate. The purity of the above-mentioned analytically pure yttrium oxide, barium carbonate, and boric acid is not less than 99.9%;

[0028] Utilize above-mentioned raw material to grow and obtain barium yttrium borate single crystal:

[002...

Embodiment 3

[0031] First prepare barium yttrium borate polycrystalline raw material:

[0032] Analytical pure yttrium oxide (Y 2 o 3 ), barium carbonate (BaCO3 ), boric acid (H 3 BO 3 ) in a molar ratio of 1:3:9.0-9.1, ground in an agate mortar and mixed evenly, then put into a platinum crucible, put the platinum crucible into a muffle furnace, heat to 940°C and keep the temperature for 12 hours , grind 5 times during the heating process to make the reactants fully react in solid phase, then turn off the power, let the sample cool down to room temperature with the furnace to get YBa 3 B 9 o 18 Polycrystalline. The X-ray diffraction spectrum of the obtained sample is shown in Figure 1, indicating that the obtained powder is barium yttrium borate. The purity of the above-mentioned analytically pure yttrium oxide, barium carbonate, and boric acid is not less than 99.9%;

[0033] Utilize above-mentioned raw material to grow and obtain barium yttrium borate single crystal:

[0034] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com