Electricity vacuum glass products lead-free seal glass and preparing method thereof

A glass product, electric vacuum technology, applied in glass manufacturing equipment, glass furnace equipment, glass molding and other directions, can solve the problems of high sealing temperature, high cost, large thermal expansion coefficient, etc., to achieve the effect of good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

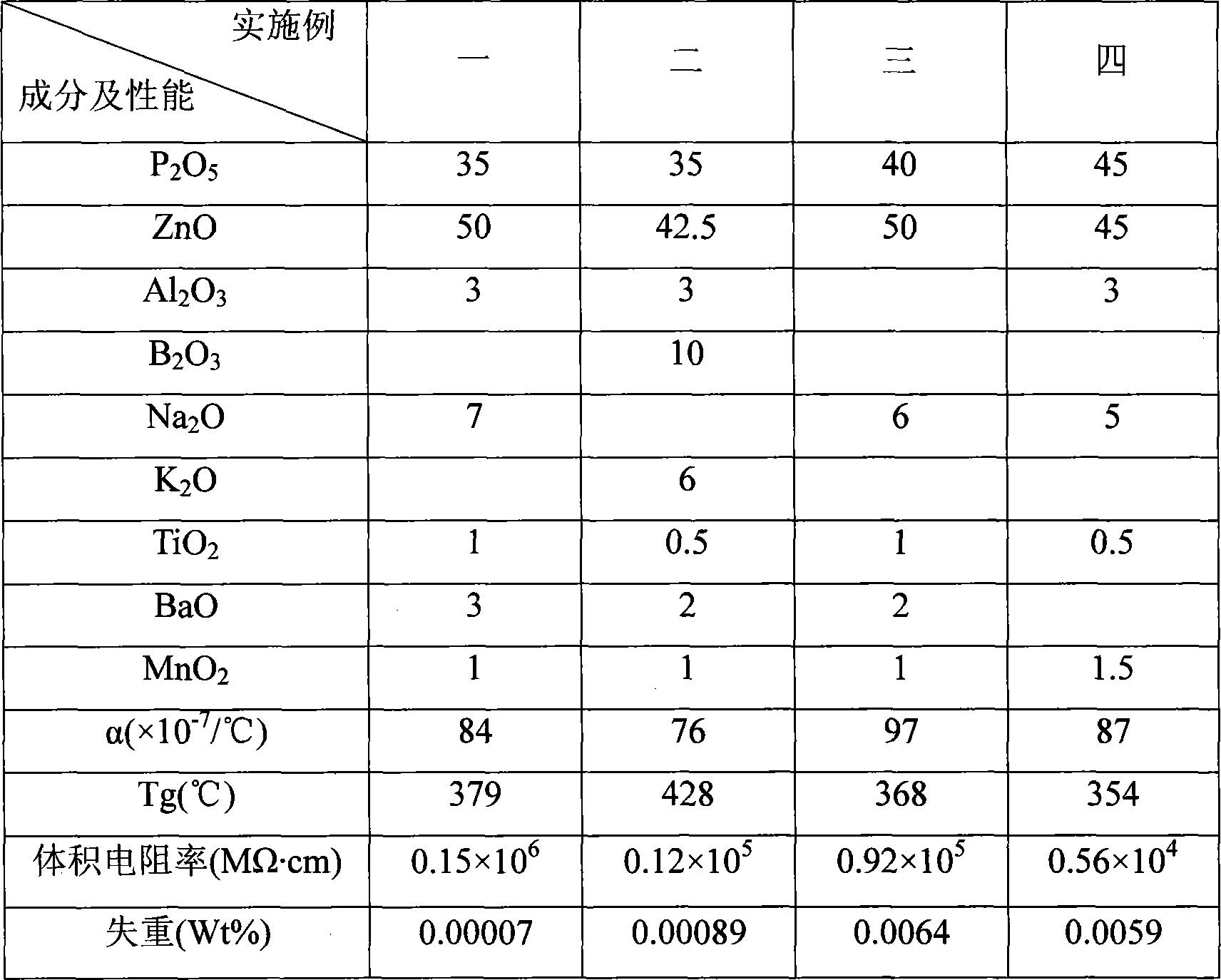

[0030] The present invention is further described in detail through the composition of specific examples 1-4.

[0031] Table 1 (mol%)

[0032]

[0033] The preparation methods of the four lead-free sealing glasses listed in the above Table 1 are the same.

[0034] Due to the volatility and high water content of phosphoric acid, at higher temperatures, the raw materials are prone to violent tumbling, resulting in P 2 o 5 Excessive volatilization cannot form glass, and the quartz crucible used is easy to break. The above problems also occur when using ammonium dihydrogen phosphate. Stratification occurs and the volatility is large. Comparative experiments have found that the use of analytically pure phosphorus pentoxide can effectively solve the above problems, the key is to mix the phosphorus pentoxide quickly, and put a lid on the crucible to reduce volatilization.

[0035] Therefore, phosphorus oxide uses chemically pure grade phosphorus pentoxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sealing temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com