Nano silver copper particle dispersant silica dioxide optical thin film and preparation method thereof

A silicon dioxide and optical thin film technology, applied in the composite field of nano metal particles and inorganic non-metallic materials, can solve the problems of large difference in deposition rate, high cost, unproven and other problems, achieve good nonlinear optical properties and short preparation period , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

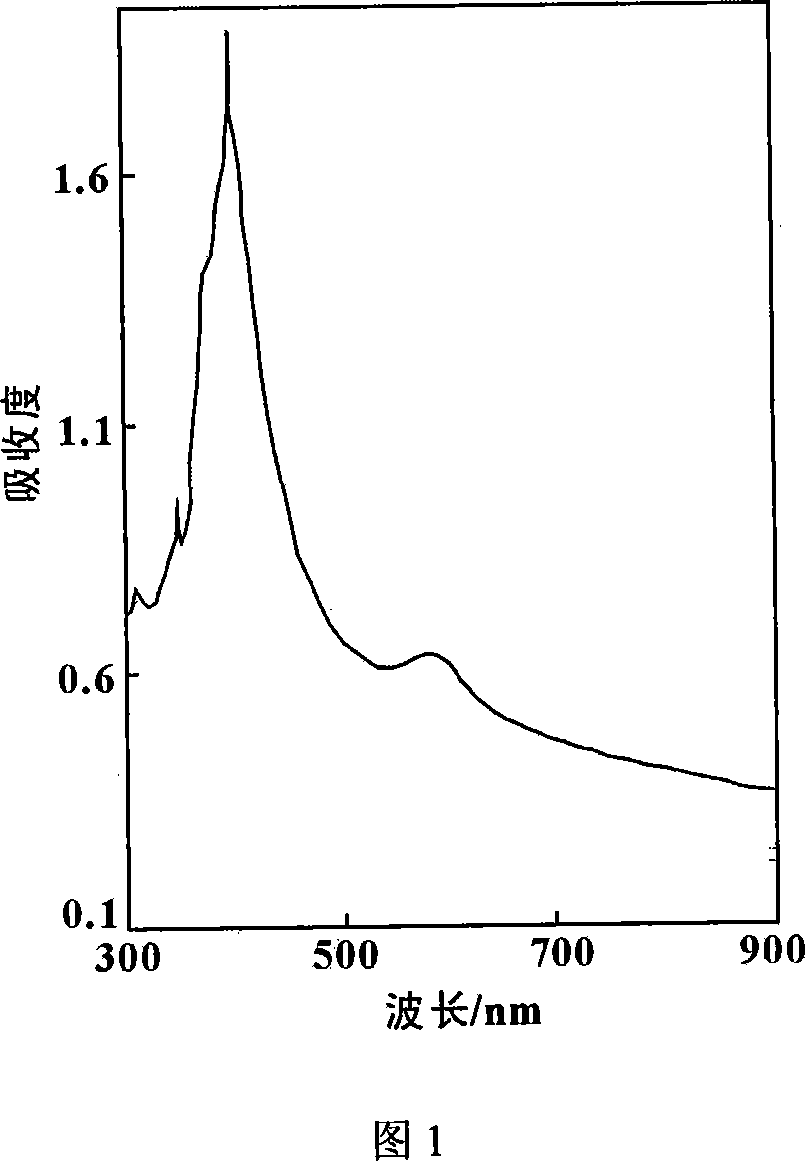

Image

Examples

Embodiment 1

[0016] Mix 2.8ml TEOS and 6.2ml H 2 O dissolved in 124.3ml CH 3 OCH 2 CH 2 OH, stirred in an ultrasonic cleaner for 20 minutes, after adding 20 drops of concentrated nitric acid, magnetically stirred for 1 hour to carry out hydrolysis and polycondensation, and then added 0.1888g Cu(NO 3 ) 2 ·3H 2 O, stirred for 2.5 hours to obtain Cu / SiO 2 solution, followed by the addition of 0.2361gAgNO 3 , and stirred again for 4 hours to obtain Ag x Cu y / (SiO 2 ) z Precursor solution; when the film is uniform, drop the solution onto the substrate, first run at 200rpm for 20 seconds, and then run at 5000rpm for 10 seconds. Every time the glue is evenly glued, the film is thermally decomposed at 100°C for 2 seconds. After 200 times of glue evenly, the sample is placed in H 2 Annealed at 900°C for 120 minutes to prepare Ag 0.15 Cu 0.05 / (SiO 2 ) 0.80 Composite film.

Embodiment 2

[0018] Mix 2.3ml TEOS and 1.8ml H 2 O dissolved in 9.2ml CH3 OCH 2 CH 2 OH, after stirring in an ultrasonic cleaner for 1 minute, add 1 drop of concentrated nitric acid, and stir for 10 hours for hydrolysis and polycondensation, then add 1.3213g Cu(NO 3 ) 2 ·3H 2 O, stirred for 2.5 hours to obtain Cu / SiO 2 solution, followed by the addition of 0.0157gAgNO 3 , and stirred again for 0.5 h to obtain Ag x Cu y / (SiO 2 ) z Precursor solution; when uniforming the film, drop the solution onto the substrate, first run at 500rpm for 6 seconds, then run at 4000rpm for 40 seconds. Every time the glue is evenly glued, the film is thermally decomposed at 150°C for 2 seconds. After 50 times of glue evenly, the sample is placed in H 2 Annealing at 600°C for 120 minutes to prepare Ag 0.01 Cu 0.35 / (SiO 2 ) 0.64 Composite film.

Embodiment 3

[0020] Mix 0.20ml TEOS and 1ml H 2 O dissolved in 8ml CH 3 OCH 2 CH 2 OH solvent, stirred in an ultrasonic cleaner for 1 minute, added 10 drops of concentrated nitric acid, stirred for 6 hours for hydrolysis and polycondensation, then added 1.3213g Cu(NO 3 ) 2 ·3H 2 O, stirred for 2 hours to obtain Cu / SiO 2 solution, followed by the addition of 0.9444gAgNO 3 , and stirred again for 1 hour to obtain Ag x Cu y / (SiO 2 ) z Precursor solution; when uniforming the film, drop the solution onto the substrate, first run at 1000rpm for 5 seconds, and then run at 1000rpm for 50 seconds. After homogenizing the glue once, the film was thermally decomposed at 600°C for 300 seconds, and then the sample was placed in H 2 Annealed at 300°C for 30 minutes in the atmosphere to prepare Ag 0.60 Cu 0.35 / (SiO 2 ) 0.05 Composite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com