Engineering bacterium producing 5-glycyl ethylformic acid and construction and application method thereof

A technology of aminolevulinic acid and engineering bacteria, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of long cultivation period, many by-products, cumbersome steps, etc., and achieve low cost and controllability The effect of high reliability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

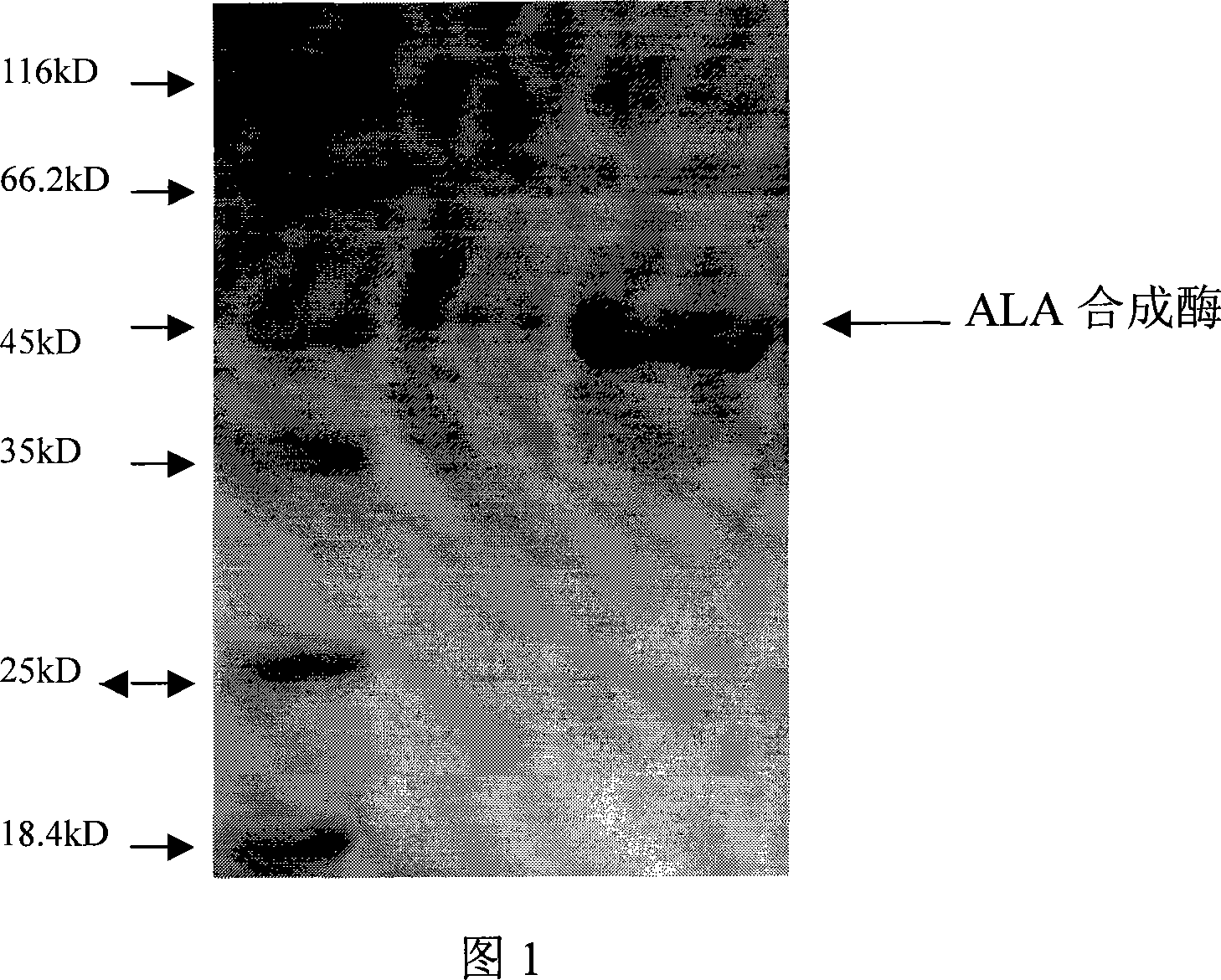

[0023] The 5-aminolevulinic acid engineering bacterium that obtains, its construction comprises the following steps:

[0024] 1. Extraction of recombinant plasmid pET28a-A.R-hemA

[0025] 1) Inoculate the engineering bacteria with the preservation number CGMCC No.1332 into the liquid medium, shake and culture at 37°C for 12 hours, and harvest the bacteria in the logarithmic growth phase;

[0026] 2) Take 3ml of bacterial culture solution (2 times, 1.5ml each time) in an Eppendorf tube, centrifuge at 13,000rpm for 30s, discard the supernatant (as complete as possible);

[0027] 3) Add 100ul of ice-precooled solution I (50mmol / L glucose; 25mmol / L TrisCl (pH8.0); 10mmol / LEDTA (pH8.0), can be prepared in batches, steam sterilized for 15min, and stored at 4°C) , shake vigorously to completely resuspend the cells, and let stand at room temperature for 5-10 minutes;

[0028] 4) Add 200ul of newly prepared solution II (0.2mol / L NaOH; 1% SDS), quickly invert 4 times, mix gently to mi...

Embodiment 2

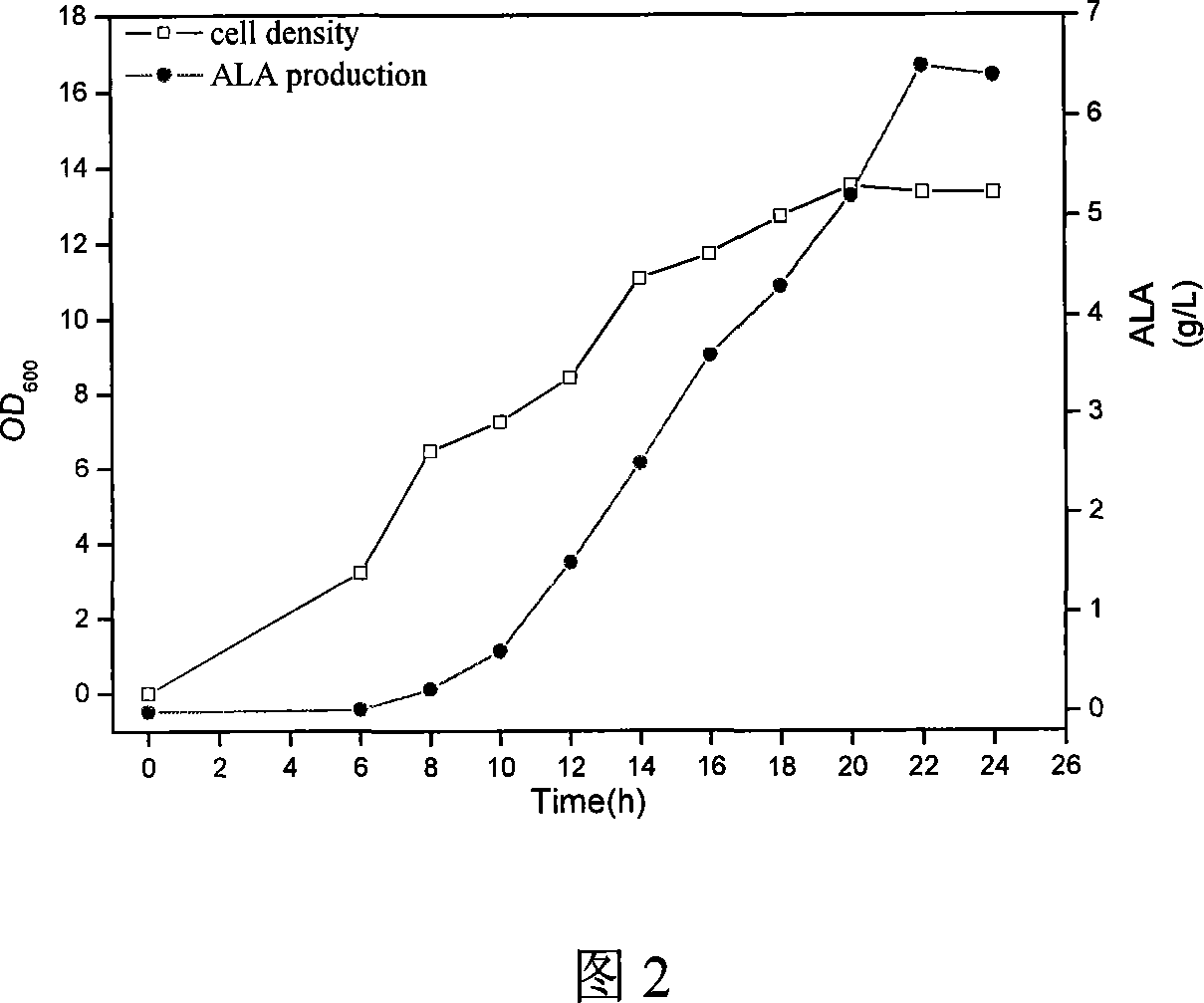

[0039] The method for producing 5-aminolevulinic acid with engineering bacteria comprises the following steps:

[0040] 1. Use an inoculation needle to dip a small amount of bacterial liquid from the glycerol tube of CGMCC No.1938 engineering bacteria Rosetta (DE3)-pET28a-A.R.hemA, and add 30 μg / ml kanamycin and 34 μg / ml chloramphenicol Streak on the LB medium plate and cultivate overnight in a 37°C oven;

[0041] 2. Pick a single clone and inoculate it in a 250ml shake flask containing 50ml LB medium at a rotation speed of 200rmp, and culture at 37°C for 8h to obtain first-grade seeds;

[0042] 3. Take 2ml of primary seeds and inoculate them in a 500ml shake flask containing 100ml of fermentation medium, and culture them at 37°C and 200rpm for 3 hours to obtain secondary seeds. Wherein the initial fermentation medium is composed of 1% peptone, 0.5% yeast powder, 0.3% succinic acid, 0.2% glycine and 0.2% glucose in mass volume ratio, and the pH value is adjusted to 5.9 with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com