Method for processing biological particles using lignin in paper-making waste liquid

A technology of biomass particles and papermaking waste liquid, which is applied in the direction of wood processing appliances, hollow objects, applications, etc., can solve the problems of rare utilization, and achieve the effects of reducing pollution, enhancing bonding, improving durability and relaxation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

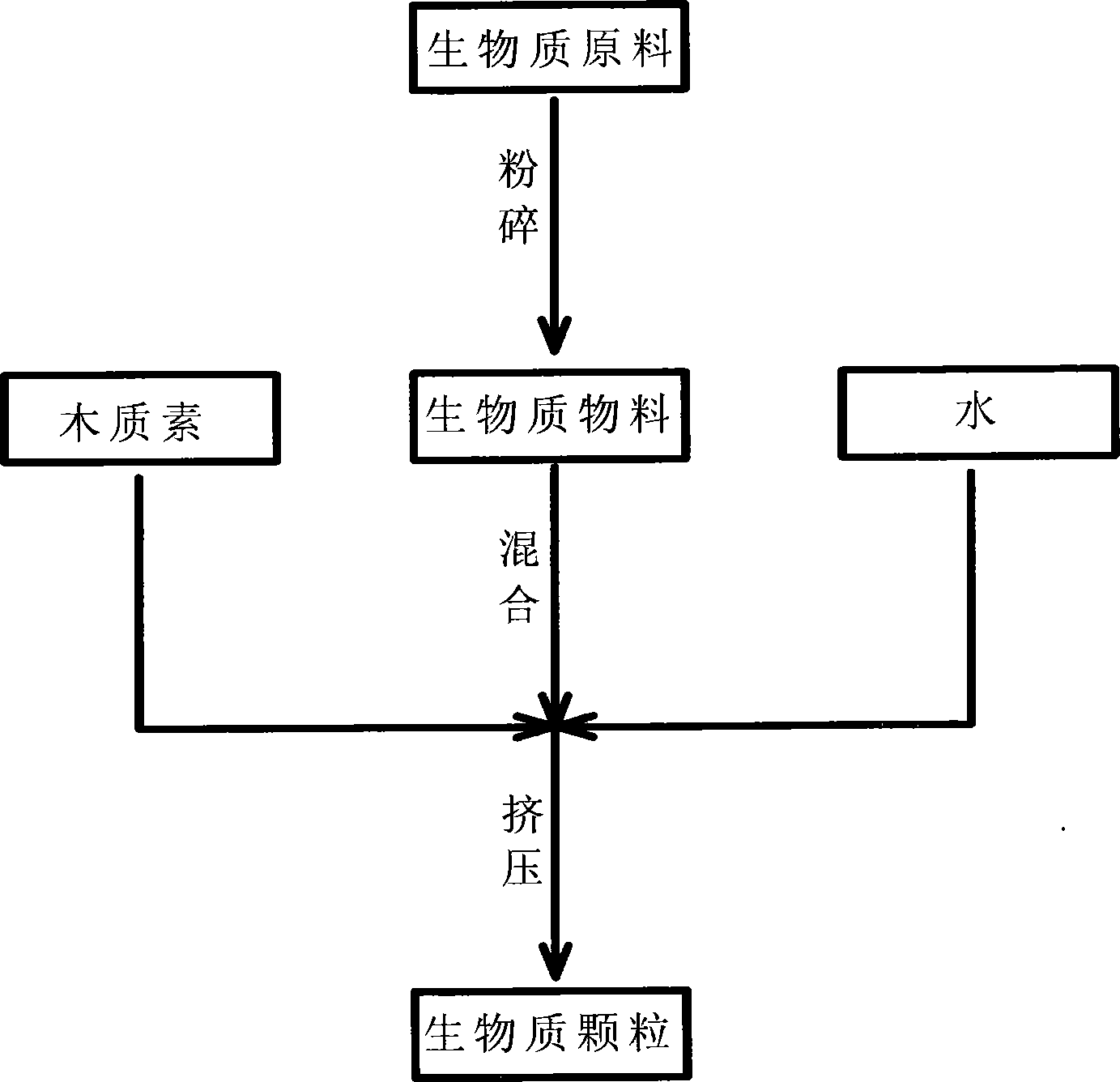

[0017] Biomass pellets are made from bark and lignin with a moisture content of less than 20% by the following steps:

[0018] 1. Pulverization: The bark is pulverized by a pulverizer and processed into a fine powder of more than 35 mesh.

[0019] Mixing: the bark fine powder and lignin are in the following weight ratio: fine powder 74%, lignin 18%, water 8%, and mix evenly.

[0020] Granulation: low-pressure extrusion molding at room temperature, the molding can use screw extrusion technology, piston extrusion technology and roller molding technology.

[0021] Drying: The formed biomass particles are heated and dried to enhance their strength.

[0022] 2. Crushing: The bark is crushed by a pulverizer and processed into particles below 35 mesh and above 15 mesh.

[0023] Mixing: the bark particles and lignin are mixed in the following weight ratio: 60% of particles, 30% of lignin, and 10% of water. well mixed.

[0024] Granulation: low-pressure extrusion molding at room te...

Embodiment 2

[0033] The processing steps of embodiment 2 are basically the same as that of embodiment 1, the difference is that the biomass particles of embodiment 2 are made of branches and lignin with a water content lower than 20%.

Embodiment 3

[0035] The processing steps of Example 3 are basically the same as those of Example 1, the difference being that the biomass particles of Example 3 are made of wood chips and lignin with a water content lower than 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com