Regeneration tower foam sulfur-film separation purification method and apparatus

A foamed sulfur and regeneration tower technology, applied in the chemical industry, can solve the problems of easy tower blockage, poor separation effect, and high energy consumption, and achieve the effects of small footprint, reduced sulfur recovery cost, and high packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

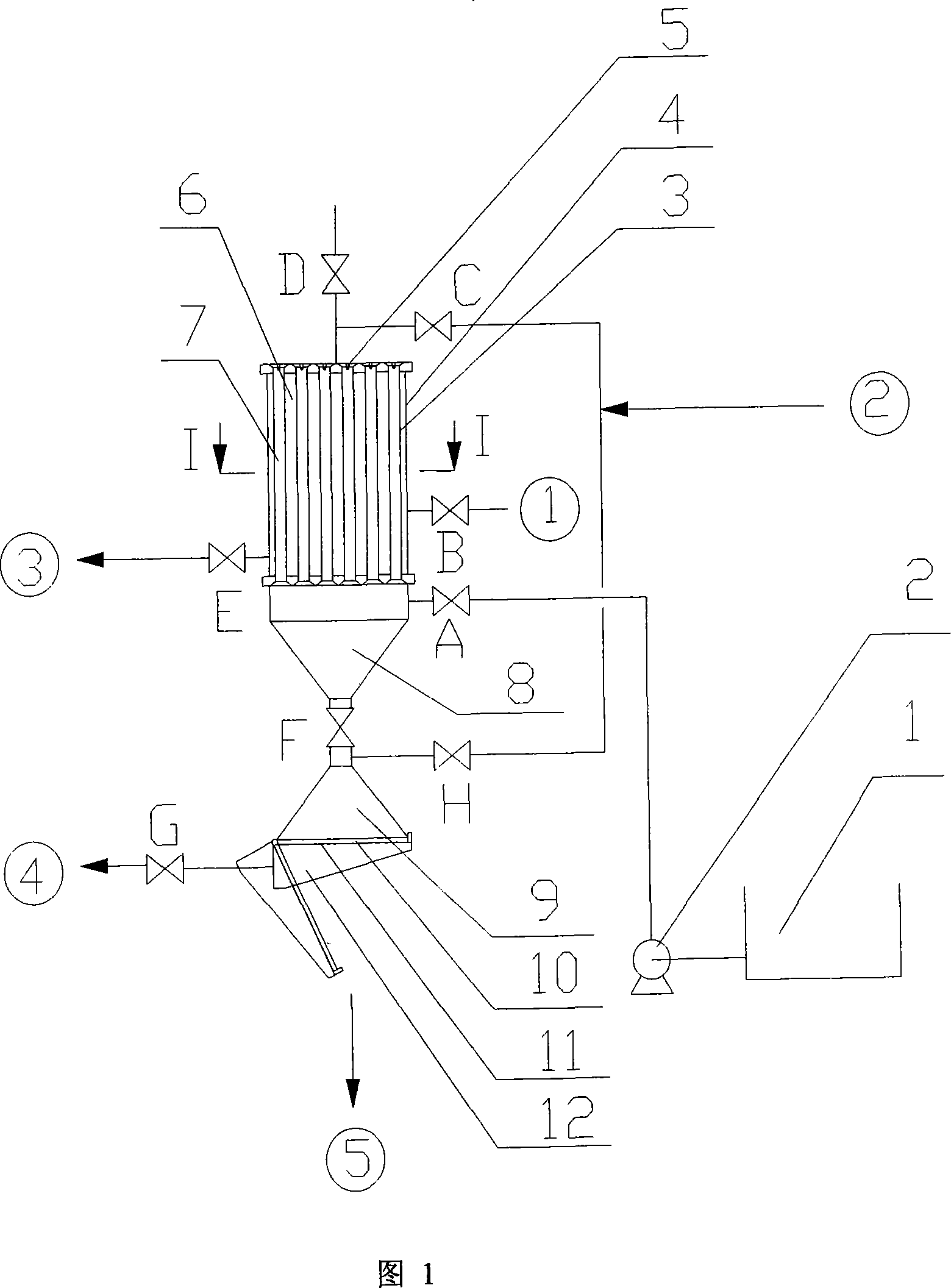

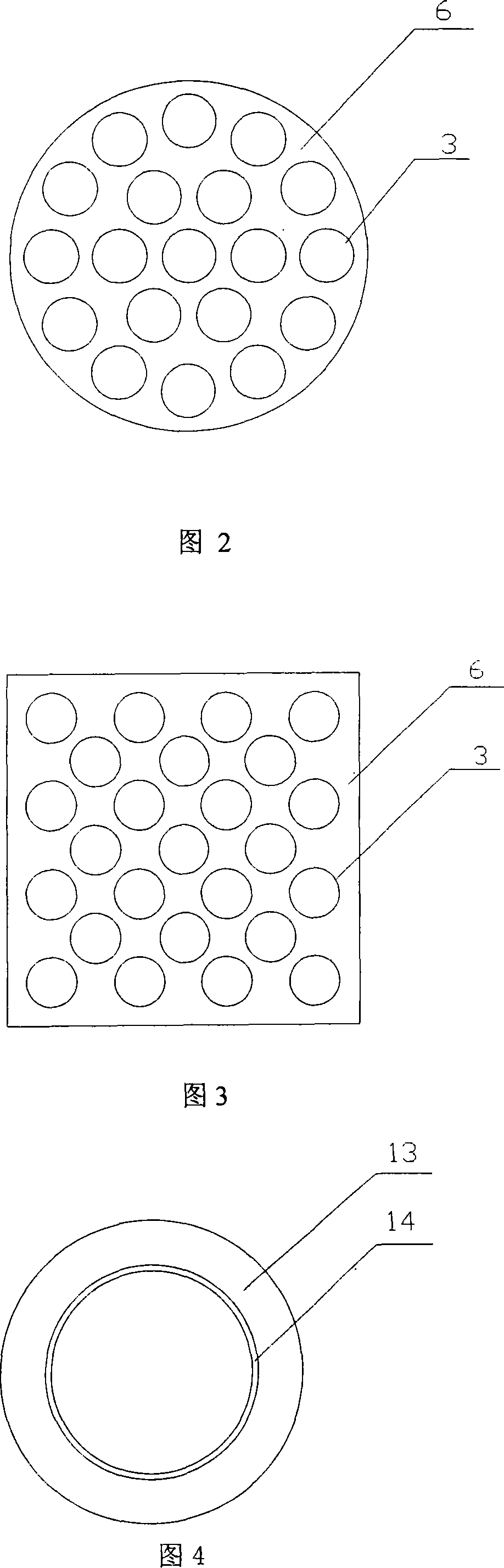

[0036](1) As shown in Figure 1, the sulfur foam at the top of the regeneration tower flows into the foam sulfur tank 1 by its own position difference, and then is sent to the membrane module 4 by the foam sulfur pump 2. The membrane module uses a 19-channel 500nmФ31 ceramic inner membrane with operating pressure It is 0.5MPa and adopts PLC automatic control. When the pressure exceeds the operating pressure, the feed valve A is automatically closed, and the discharge valve F and the backflush valve B at the bottom are opened at the same time, and 0.7MPa high-pressure steam is used to backflush the membrane hole 8S, The sulfur paste in the membrane channel is melted into a liquid, then the recoil valve B is closed and the channel purge valve C is opened at the same time, the membrane channel is purged with 0.7MPa compressed air ②, and the discharge valve F is opened at the same time to discharge.

[0037] (2) The material of the dehydrator 8 is 400 mesh polypropylene twill industria...

Embodiment 2

[0043] (1) As shown in Figure 1, the sulfur foam on the top of the regeneration tower flows into the foam sulfur tank 1 by its own position difference, and then is sent to the membrane module 4 by the foam sulfur pump 2. The membrane module uses a single-channel 200nmФ12 ceramic inner membrane, and the operating pressure It is 0.8MPa and adopts PLC automatic control. When the pressure exceeds the operating pressure, the feed valve A is automatically closed, and the discharge valve F and the backflush valve B at the bottom are opened at the same time. The sulfur paste in the membrane channel is melted into a liquid, then the recoil valve B is closed and the channel purge valve C is opened at the same time, the membrane channel is purged with 1MPa compressed air ②, and the discharge valve F is opened at the same time to discharge.

[0044] (2) The material of the dehydrator 8 is 600 mesh polyester twill industrial filter cloth. At the end of the discharge of the membrane module 4, c...

Embodiment 3

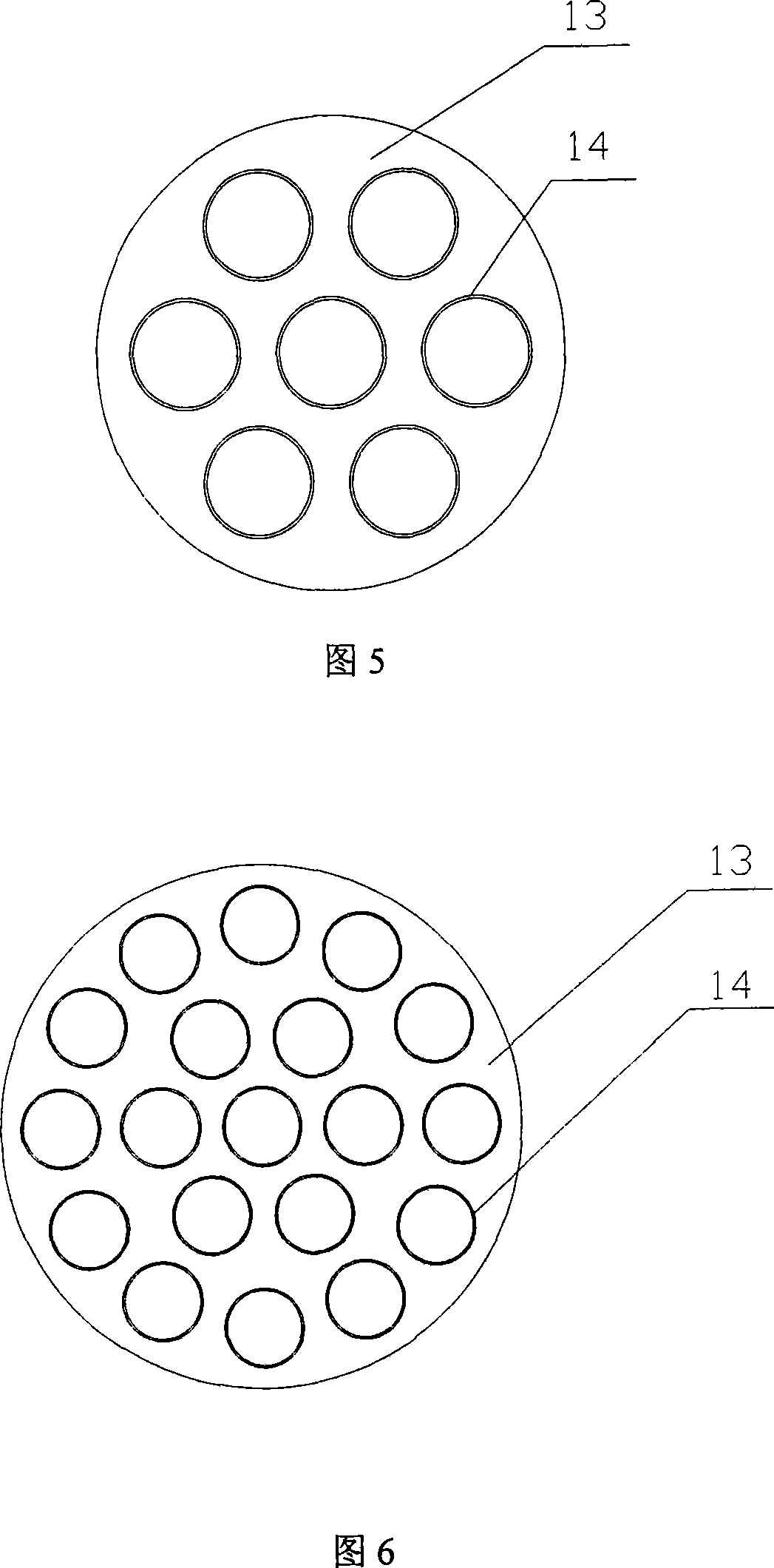

[0050] (1) As shown in Figure 1, the sulfur foam at the top of the regeneration tower flows into the foam sulfur tank 1 by its own position, and then is sent to the membrane module 4 by the foam sulfur pump 2. The membrane module adopts a 7-channel inner membrane of 1μmФ31 polyethylene material. , The operating pressure is 0.2MPa, and it is automatically controlled by PLC. When the pressure exceeds the operating pressure, the feed valve A is automatically closed, and the bottom discharge valve F and the backflush valve B are opened at the same time, and 0.5MPa high-pressure steam is used to backflush the membrane. Hole 15S to melt the sulfur paste in the membrane channel into a liquid, then close the backflush valve B and open the channel purge valve C at the same time, use 0.5MPa compressed air ② to purge the membrane channel, and open the discharge valve F to discharge the material.

[0051] (2) The material of the dehydrator 8 is 400 mesh polyester twill industrial filter cloth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com