Thermoplastic polyimide composite material and its production

A composite material and polyimide technology, applied in the field of thermoplastic polyimide-based composite materials and its preparation, to achieve excellent comprehensive performance, easy operation, and the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

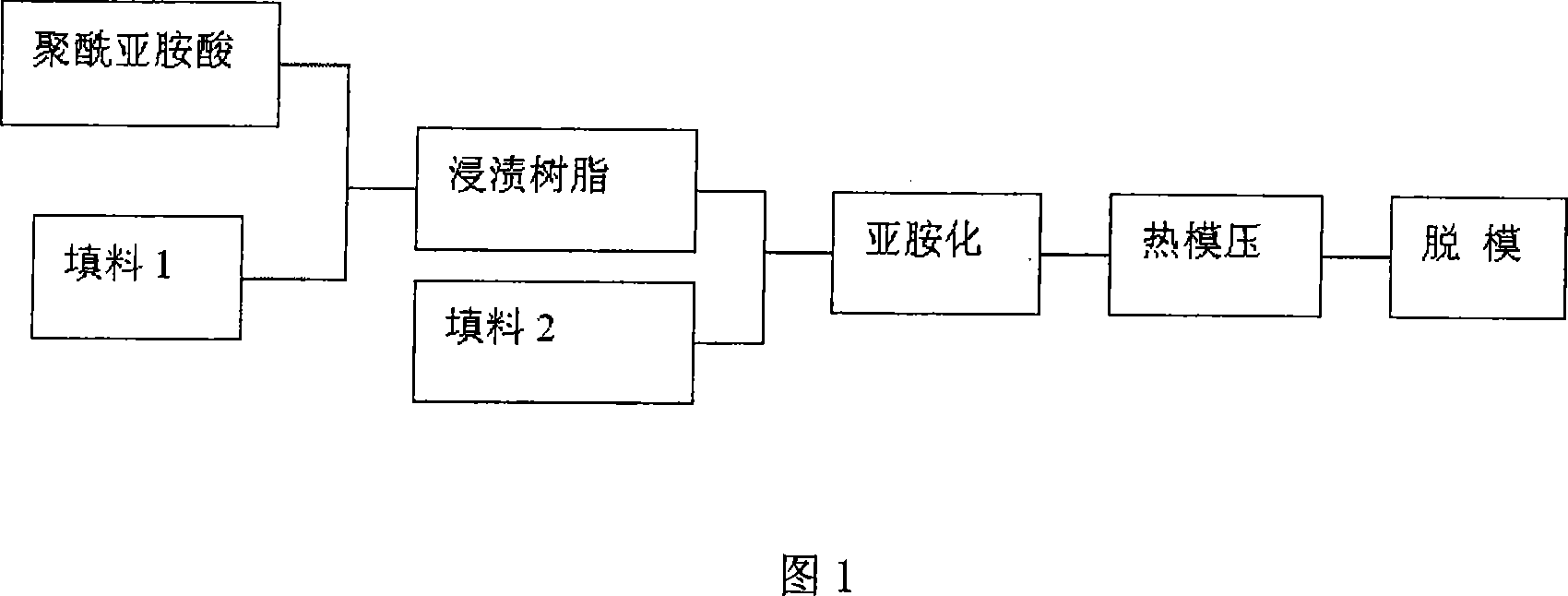

Method used

Image

Examples

Embodiment 1

[0029] Select 500g of ABRON-S10 polyamic acid solution from ABR Organic Compound Company, the product report intrinsic viscosity is 1.5~2.5dL / g, and the solid content is 10%, so the solid content of polyamic acid can be calculated to be 50g; 30g of powdery graphite with a particle size of 200 meshes was stirred at high speed for 2 hours to obtain powdery graphite / polyamide impregnated resin. Dip-coat the impregnated resin on the unidirectional carbon fiber cloth with a thickness of 0.20mm, and repeatedly dip-coat until the thickness reaches 0.35mm. According to the usage amount of the polyimide acid solution, it can be determined that the addition amount of the thermally conductive filler 2 is 25 g. Put the obtained greige in an oven for imidization treatment, program the temperature from 100°C to 300°C for 3 hours, and then take it out of the oven after cooling down to 30°C to obtain imidized polyimide Composite fabric. The above-mentioned polyimide composite gray cloth is ...

Embodiment 2

[0031] Select N,N'-dimethylacetyl as the solvent, prepare 700g of polyamic acid solution with a solid content of 10%, and the intrinsic viscosity is 2.0dL / g, so the solid content of the polyamic acid can be calculated to be 70g; 30 g of flaky graphite with a particle size of 300 meshes was stirred at high speed for 2 hours to obtain flaky graphite / polyamide impregnated resin. Dip-coat the impregnated resin on the single-weft carbon fiber cloth with a thickness of 0.25mm, and repeat the dip-coating until the thickness reaches 0.50mm. According to the amount of polyimide acid solution used, it can be determined that the amount of thermally conductive filler 2 added is 32 g. Put the obtained greige in an oven for imidization treatment, program the temperature from 100°C to 300°C for 3 hours, and then take it out of the oven after cooling down to 30°C to obtain imidized polyimide Composite fabric. The above-mentioned polyimide composite gray cloth is cut and stacked according to...

Embodiment 3

[0033]Select N-methylpyrrolidone as a solvent to prepare 600g of polyamic acid solution with a solid content of 10%, and the intrinsic viscosity is 1.7dL / g, so that the solid content of polyamic acid can be calculated to be 60g; adding 30g of polyamic acid with a particle size of 700-mesh copper powder was stirred at high speed for 2 hours to obtain flaky graphite / polyamide impregnated resin. Dip-coat the impregnating resin on the bidirectional carbon fiber plain weave cloth with a thickness of 0.32mm, and repeatedly dip-coat until the thickness reaches 0.60mm. According to the amount of polyimide acid solution used, it can be determined that the added amount of the thermally conductive filler 2 is 18 g. Put the obtained greige into an oven for imidization treatment, program the temperature from 100°C to 300°C for 3 hours, and then take it out of the oven after cooling down to 40°C to obtain imidized polyimide Composite fabric. The above polyimide composite gray cloth is cut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com