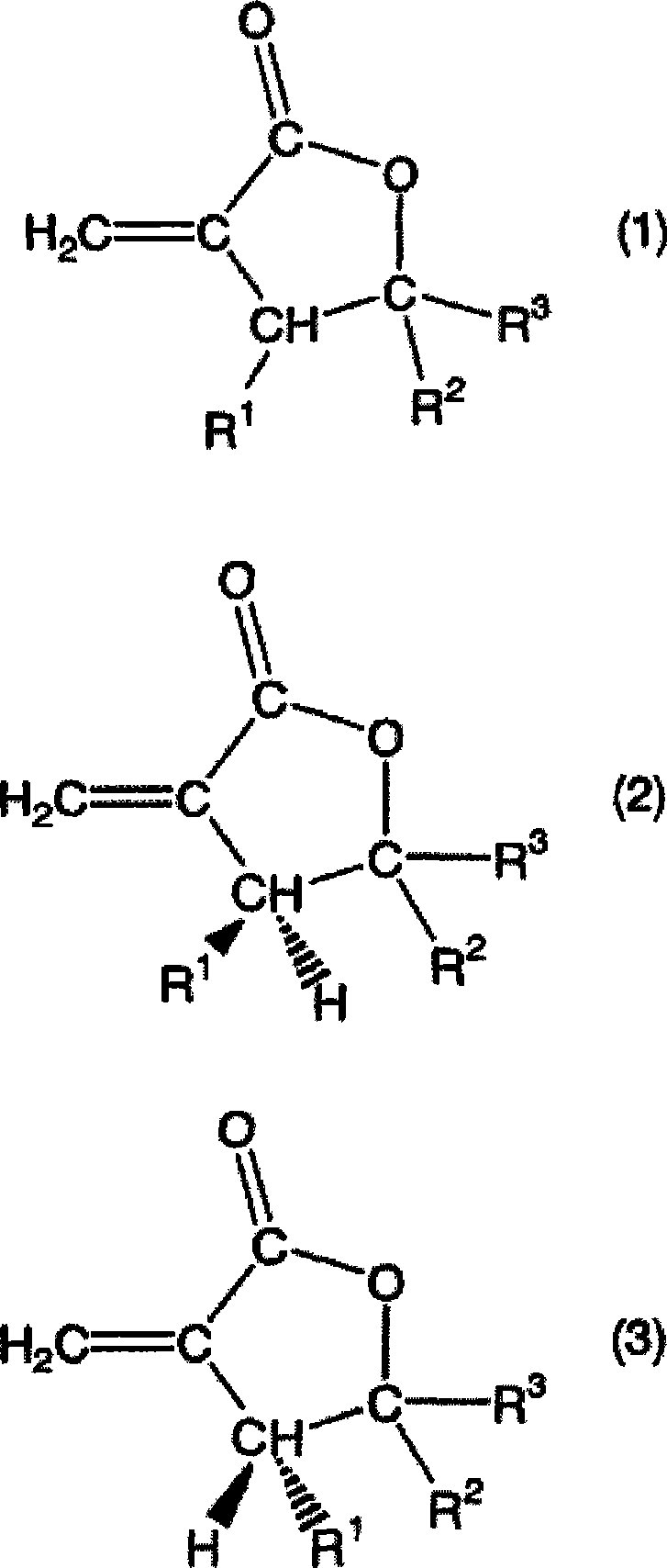

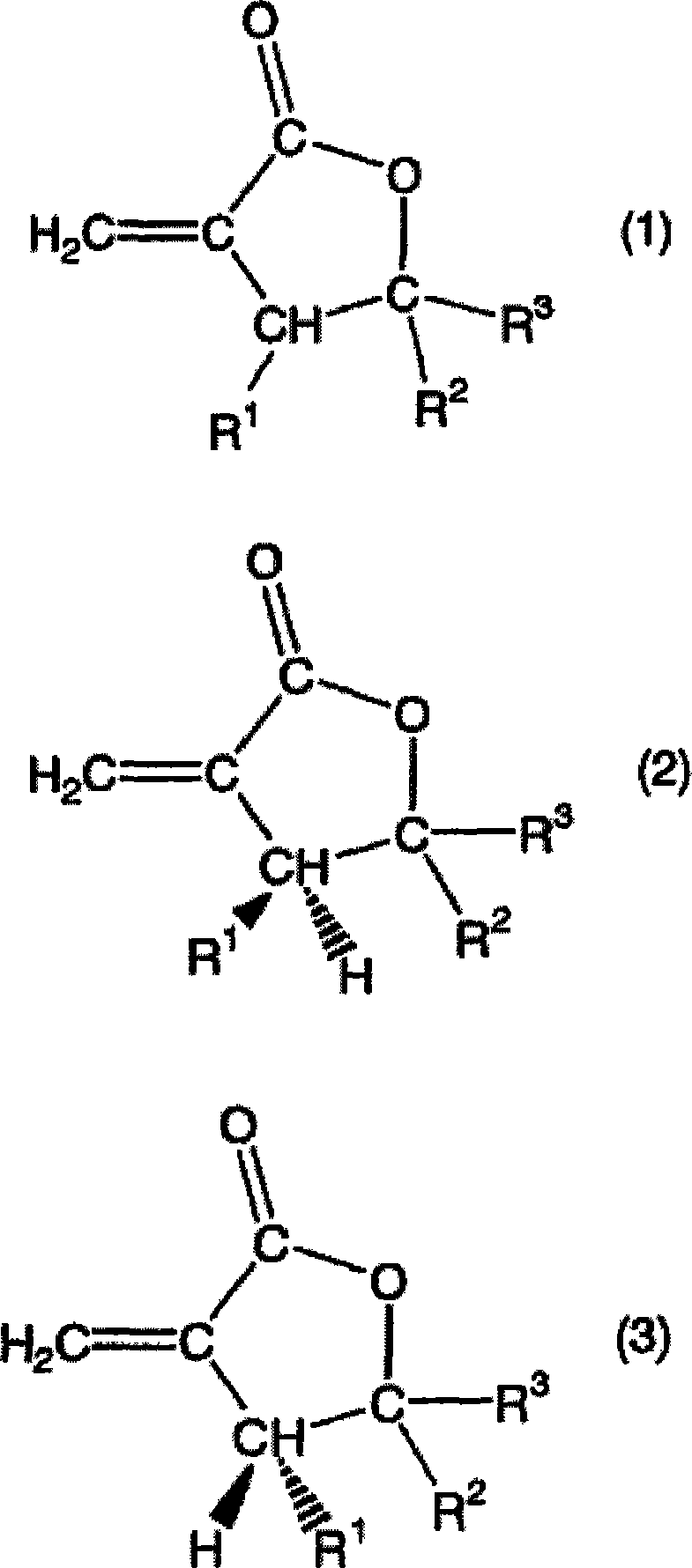

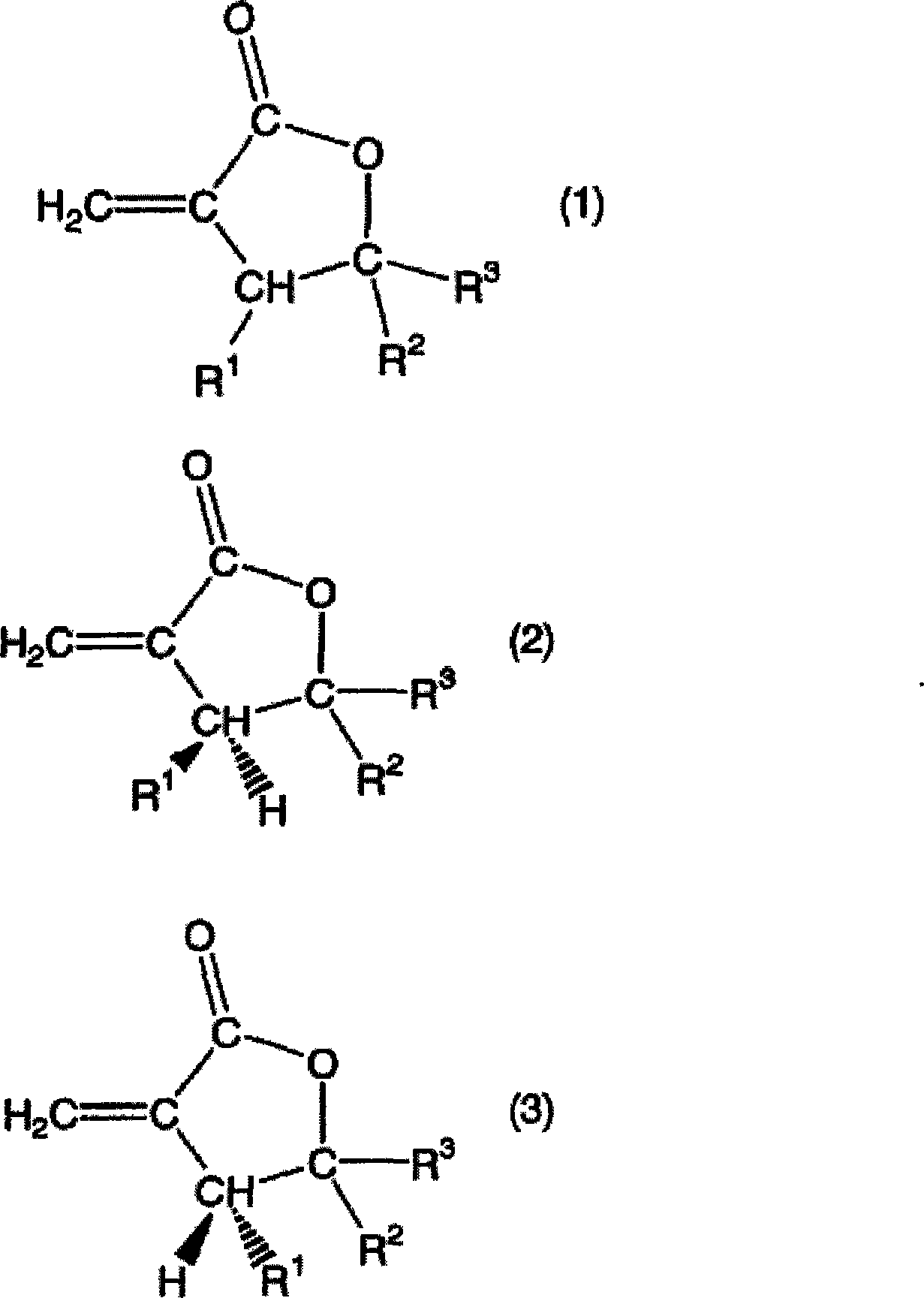

Polymer composition, plastic optical fiber, plastic optical fiber cable and method for producing plastic optical fiber

A plastic optical fiber, polymer technology, applied in optics, light guides, optical components, etc., to achieve the effect of reducing transmission loss, excellent transparency, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0255] Mix 50 parts by mass of each of (R)-βMMBL obtained in (Synthesis 7) and (S)-βMMBL obtained in (Synthesis 8) to obtain a mixture of (R) and (S) bodies of β MMBL ((R / S)-βMMBL) (h).

[0256] In a beaker, 0.3 parts by mass of a polymerization initiator dimethyl 2,2'-azobisisobutyrate (V-601), 0.3 g The chain transfer agent n-butyl mercaptan of parts by mass is stirred. Put the stirred and dissolved mixture into a glass ampoule tube, repeat freezing and vacuum removal of volatile components 5 times, remove dissolved oxygen, heat treatment at 65°C for 12 hours in an oil bath, and then heat treatment at 120°C for 5 hours to complete the polymerization.

[0257] The obtained massive polymer was dissolved in methylene chloride, precipitated with methanol, filtered, washed with water, and dried at 75° C. for 24 hours to obtain a polymer. Thereafter, it was extruded at a barrel temperature of 230° C. using a twin-screw extruder (PCM30, manufactured by Ikegai Co., Ltd.), and pe...

Embodiment 2~7、 comparative example 1~7

[0261] Except for changing the composition of the mixture of (R)-βMMBL and (S)-βMMBL and MMA as shown in Table 1, polymerization, granulation, production of test pieces were carried out in the same manner as in Example 1, and various evaluations were performed. The obtained evaluation results are shown in Table 1 together.

Embodiment 8~11、 comparative example 8~11

[0263] Except for changing the composition of the mixture of (R)-βMMBL and (S)-βMMBL and MMA as shown in Table 2, polymerization, granulation, preparation of test pieces were carried out in the same manner as in Example 1, and light transmittance was evaluated. . Table 2 shows the obtained evaluation results together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| enthalpy of fusion | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com