Complex formulation of 3-hydroxy-3-methyl glutaryl coa reductase inhibitor and antihypertensive agent, and process for preparing same

A reductase inhibitor and anti-hypertensive technology, applied in pill delivery, drug combination, pharmaceutical formula, etc., can solve the problems that the therapeutic effect cannot be maintained for a long time, liver toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

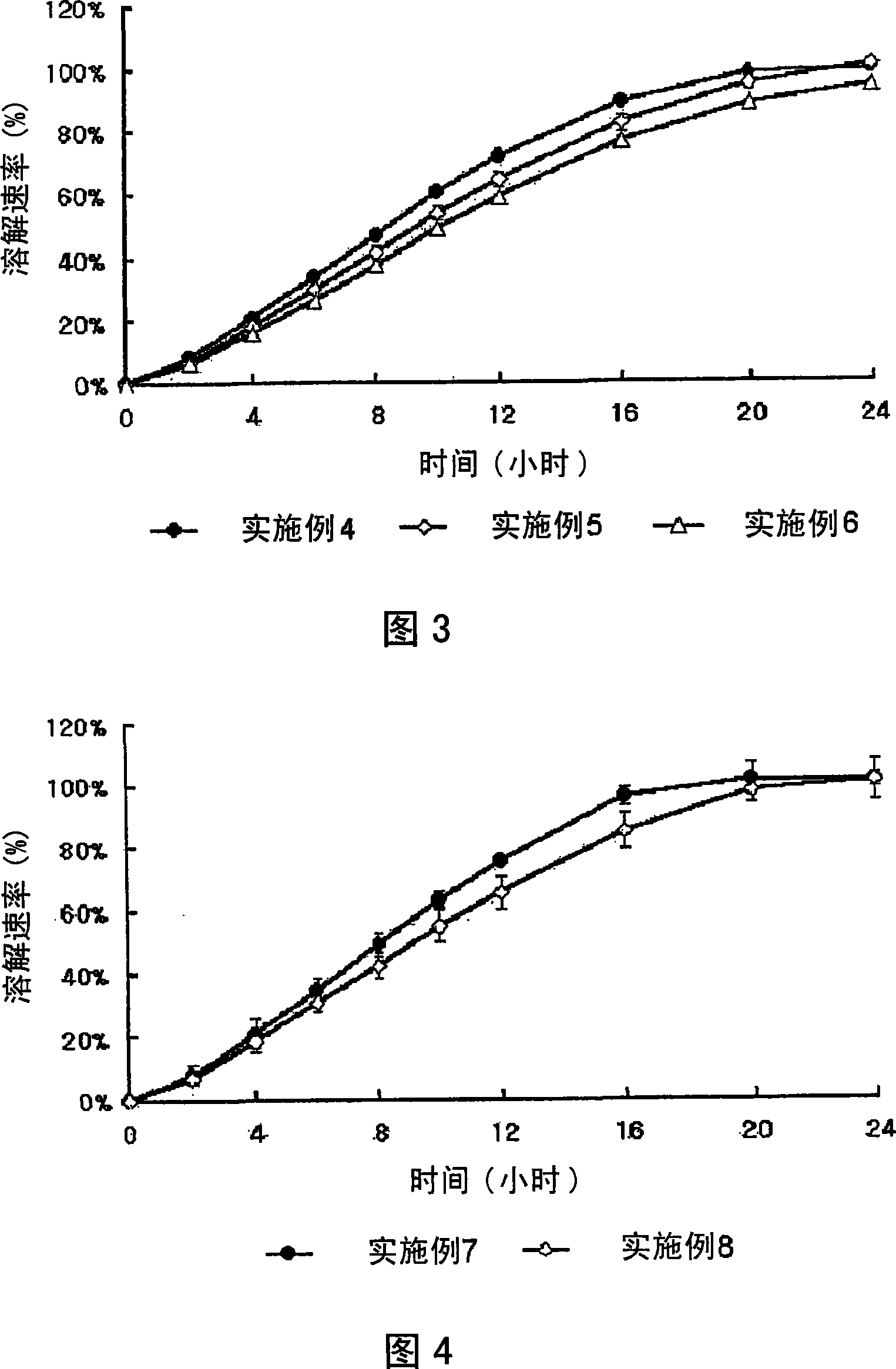

Embodiment 1 to 3 and comparative example 1

[0062] Examples 1 to 3 and Comparative Example 1: Preparation of Solid Dispersion

[0063]Simvastatin (Hanmi Fine Chemical Co., Ltd., Korea), MYRJ (ICI, USA), HPMC 2910 (viscosity: 3 to 15cps, Shin-Etsu, Japan), BHT (UENO Fine Chemical, USA) and light Quality anhydrous silicic acid (as a dispersant) was dissolved in a mixture of ethanol and dichloromethane according to the amounts described in Table 1, and each resulting mixture was spray-dried to obtain particles with an average particle size of 100 μm or less. solid dispersion. The solid dispersions of Examples 1 to 3 and Comparative Example 1 thus obtained are shown in Table 1.

[0064]

[0065] components

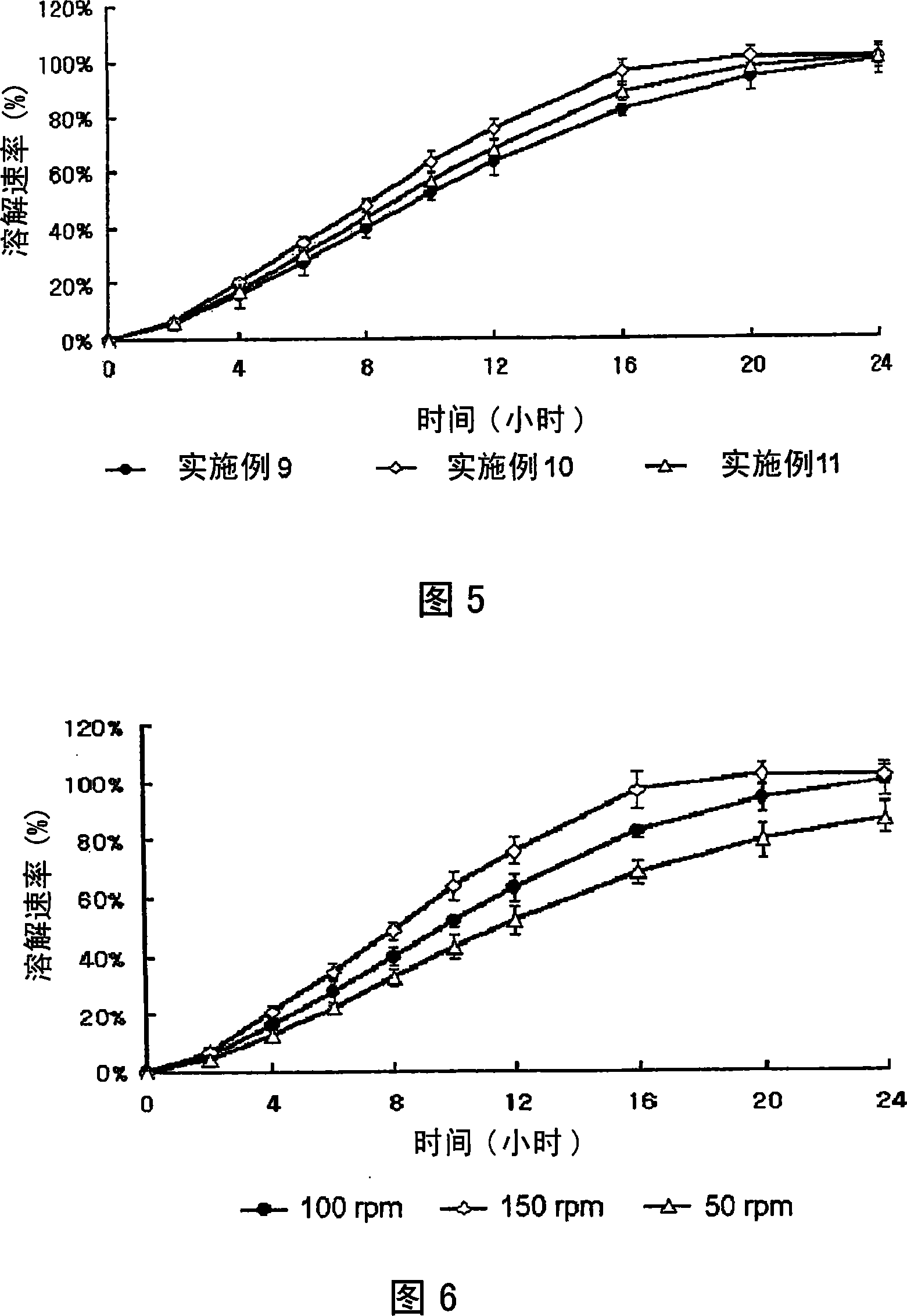

Embodiment 4 to 8

[0066] Examples 4 to 8: Preparation of sustained-release dosage forms for oral administration

[0067] According to the amounts described in Tables 2 to 4, respectively utilizing simvastatin, lovastatin or fluvastatin as active ingredients, together with MYRJ, HPMC 2910, BHT, and light anhydrous silicic acid, the procedure of Example 1 was repeated to obtain A solid dispersion is obtained. Then, each solid dispersion was mixed with xanthan gum (Kelco, USA), locust bean gum (Cesalpinia, Italy), propylene glycol alginate (ISP, USA), HPMC 2208 (viscosity: 4,000 to 100,000 cps, Shin -Etsu, Japan) and erythorbic acid were mixed for about 30 minutes; and sucrose fatty acid ester and light anhydrous silicic acid powder (finer than 40 mesh) were added and mixed for 5 minutes. Each of the resulting mixtures was molded into a block using a molding assembly, and the block was pulverized into particles having a mesh size ranging from 20 to 80. The granules are then formulated into tab...

Embodiment 9 to 11

[0074] Examples 9 to 11: Preparation of combination dosage forms for oral administration

[0075] Each sustained-release dosage form obtained in Examples 5, 7 and 8 was coated with Opadry AMB (Colorcon) film. Amlodipine camphorsulfonate (Hanmi Fine Chemical Co., Ltd., Korea), HPMC 2910 (viscosity: 3 to 15 cps) and acetylated monoglyceride (Myvacet) were dissolved respectively according to the amounts described in Table 5 In a mixture of ethanol and dichloromethane, it was applied to the film-coated formulations described above.

[0076]

[0077] components

(mg / tablet)

Example 9

Example 10

Example 11

Sustained-release dosage form core

Example 5

Example 7

Example 8

Active into

Minute

Ammonium D-camphorsulfonate

Clodipine

7.9

7.9

7.9

coating agent

HPMC 2910

10

10

10

Myvacet

1.6

1.6

1.6

stabilizer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com